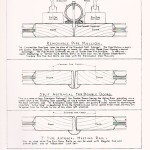

FF: Unequal Leaf Pair

This is not how I would have specified the hardware for this unequal leaf pair. I think the panic hardware on the small leaf actually results in an opening that is less safe, because the removable mullion makes the small leaf difficult or impossible to use...