This Decoded article on clear opening requirements was first published almost 10 years ago, and remains a frequently visited post on iDigHardware. It has now been updated with current code references.

This post was published in Doors & Hardware

At the beginning of my career in the hardware industry, there was a lot of confusion about how to measure the clear opening width of doors. The codes and standards weren’t specific, so on doors with panic hardware, some fire marshals were taking the projection of the hardware into account when measuring the clear width. Since then, the codes and standards have been clarified, and now include instructions for how to measure the width of a door opening; acceptable projections into the required clear opening width are also defined.

At the beginning of my career in the hardware industry, there was a lot of confusion about how to measure the clear opening width of doors. The codes and standards weren’t specific, so on doors with panic hardware, some fire marshals were taking the projection of the hardware into account when measuring the clear width. Since then, the codes and standards have been clarified, and now include instructions for how to measure the width of a door opening; acceptable projections into the required clear opening width are also defined.

These requirements are found in the International Building Code (IBC), the International Fire Code (IFC), ICC A117.1 – Accessible and Usable Buildings and Facilities, the 2010 ADA Standards for Accessible Design, and NFPA 101 – The Life Safety Code, as well as state and local codes. Note that the minimum clear opening width does not apply only to doors on an accessible route, but also to doors in a means of egress.

Clear Opening Width Requirements:

- Doors must typically provide a minimum of 32 inches of clear opening width.

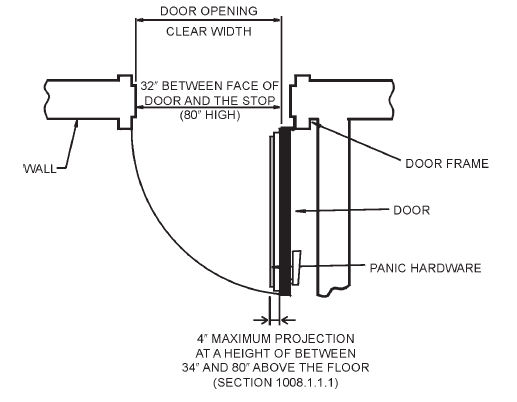

- Clear opening width is measured between the face of the door and the stop on the strike jamb, with the door open 90 degrees. If necessary, swing-clear hinges may be used to increase the clear opening width, by relocating the 90-degree position of the door.

- For pairs of manually-operated doors, at least one leaf of the pair must provide 32 inches of clear opening width, when measured from the face of the open door to the edge of the inactive leaf in the closed position (or to the mullion). When replacing an existing pair of 30-inch doors, an unequal-leaf pair is usually required.

- For pairs of automatic doors, the accessibility standards allow the full width of the opening (the clear width of all leaves in the open position) to be taken into account when measuring the clear opening width. Adding automatic operators may be an acceptable way to resolve clear width problems on existing doors. Note that the IBC requires one leaf of a pair to provide 32 inches clear, and does not differentiate between manually-operated and automatic doors with regard to clear opening width.

- Sliding and folding doors in most locations must also provide at least 32 inches of clear opening width. Accessibility standards require sliding doors – including pocket doors, to have surface-mounted hardware. This hardware may prevent the doors from sliding fully open; potentially affecting the clear opening width.

Openings (with or without doors) that are more than 24 inches deep must provide a clear opening width of at least 36 inches (see photo at right).

Openings (with or without doors) that are more than 24 inches deep must provide a clear opening width of at least 36 inches (see photo at right).- No projections are allowed into the required clear opening width between the floor and a point 34 inches above the floor. This does not necessarily mean that nothing can project off the door; it means that nothing can project into the 32-inch required clear width dimension (note that manual doors on an accessible route are not allowed to have any projections on the push side between the floor and 10 inches above the floor).

- Projections into the clear opening width of up to 4 inches are allowed between 34 inches and 80 inches above the floor. Since operable hardware is required to be mounted between 34 inches and 48 inches above the floor (or as required by state codes), hardware is not taken into account unless it projects more than 4 inches into the clear opening width. Note that NFPA 101 limits these 4-inch projections to the hinge side of the opening, between 34 inches and 48 inches above the floor, solely for the purpose of accommodating panic hardware or fire exit hardware.

- Projections into the clear opening width above 80 inches are not limited by the model codes or referenced standards.

- Some occupancy types require a greater clear opening width; for example, hospital doors used for the movement of beds are required to provide at least 41 ½ inches of clear opening width.

- Past editions of the model codes limited the maximum width of an egress door to 48 inches. This dimension is not the maximum clear opening width, but the maximum door size. This maximum dimension has been removed from recent editions of NFPA 101, and from the IBC and IFC beginning with the 2021 edition.

- There are exceptions within the codes for some applications – for example, the IBC includes exceptions related to some doors in residential occupancies, Group I-3 sleeping rooms, small storage closets, and revolving doors. There is also an exception related to automatic sliding doors in break out / break away mode.

The codes and standards also include requirements for the minimum clear opening height of a door opening. The minimum headroom requirement is typically 80 inches nominal above the floor, with an allowance for the projection of the stop on the frame head. Most publications have an exception for a door closer arm or overhead stop arm, which is allowed to project down into the required opening height as long as a dimension of 78 inches of headroom is maintained. Other projections, such as electromagnetic locks, are not currently addressed in the accessibility standards, however, the 2021 edition of the IBC includes a change that allows automatic operators and electromagnetic locks to project down to the 78-inch location.

There are some exceptions to the requirements for the 32-inch clear opening width and 80-inch clear opening height, but typically these are the dimensions to keep in mind when specifying or supplying doors and hardware on an accessible route or in a means of egress. Consult the applicable codes for exceptions.

Graphic: International Building Code Commentary

You need to login or register to bookmark/favorite this content.

Leave A Comment