This post was published in Doors & Hardware

For many of us, the current area of focus with regard to school safety and security is protection from intruders, and with good reason. Schools should be designed and equipped to keep children safe when they’re away from home. But a danger is present in many of the schools and other buildings we visit that most of us aren’t even aware of – traditional wired glass that can cause severe and life-threatening injuries when subjected to human impact.

For many of us, the current area of focus with regard to school safety and security is protection from intruders, and with good reason. Schools should be designed and equipped to keep children safe when they’re away from home. But a danger is present in many of the schools and other buildings we visit that most of us aren’t even aware of – traditional wired glass that can cause severe and life-threatening injuries when subjected to human impact.

Many people believe that traditional wired glass – the glass with criss-crossed wires creating diamonds or squares, is “safety glass,” and that it is more secure than other types of glass. The reality is the exact opposite. The wires used in traditional wired glass weaken the glass – it is only half as strong as ordinary annealed glass. And when traditional wired glass breaks, it forms large sharp pieces which are held in place by the wires. When an adult or child impacts the glass, and an arm, leg, or other part of their body projects through, they will then typically pull the injured limb back through the broken glass, causing further injury.

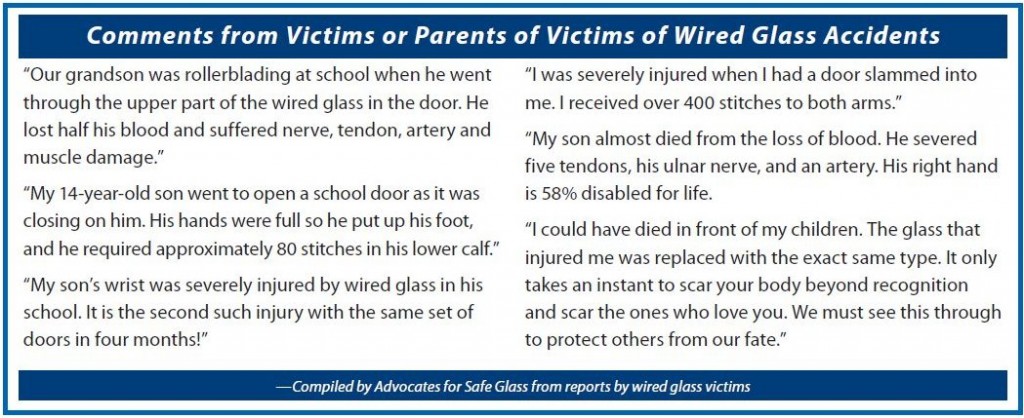

While the threat of an intruder entering a school building is statistically unlikely, injuries related to traditional wired glass occur frequently. In 2002, an epidemiologic study of the Consumer Product Safety Commission (CPSC) injury data was conducted by a professor from Emory University – Philip L. Graitcer, DMD, MPH. Of the 2,554 glass door injuries that occurred in U.S. schools in a 1-year period, Dr. Graitcer stated that he would “conservatively estimate that 90% of the 2,500 glass door injuries seen each year in the CPSC system involved wired glass.” That is 2,250 wired glass injuries – in our nation’s schools – in one year. These injuries are often debilitating and life-altering, some even result in death due to blood loss. Also compelling – the hundreds of thousands of dollars in damages paid annually in the legal cases which arise because of these injuries.

These doors were installed within the last six months and contain traditional wired glass, even though the doors are not fire-rated and the code requires impact-resistant glass in all doors.

The Ontario School Boards’ Insurance Exchange (OSBIE) compiled a statistical analysis of the risks of injuries, after paying out over $3,000,000 to settle injury claims. Their report states: “OSBIE receives many reports of incidents and notices of claims with respect to injuries received by students seriously cut through impact with glass. Many of these injuries are cause by wired safety glass in schools. From 1987 to 2000 there have been 107 claims against schools for glass injuries. Over this period, costs related to glass injuries amounted to $3,154,202. More important than the dollars is the pain and suffering, permanent reduced mobility and scarring caused by these impacts with glass.”

Safety Glass Standards

You may be wondering why wired glass was ever allowed to be installed in locations where human impact was likely, creating a hazard for decades to come. Prior to the 1960’s, the building codes were silent on the subject of safety glazing. But because of numerous lawsuits, glass manufacturers recognized the need for industry standards. A task group was formed and their studies found an average of 320,000 injuries per year from people impacting glass in doors and windows (all building types including residential). In 1966, the standard developed by this task group was accepted as a national standard called ANSI Z97.1 – American National Standard for Safety Glazing Materials Used in Buildings.

When the Consumer Product Safety Commission was created in 1972, one of their first initiatives was to address the standards for safety glazing. The Safety Standard for Architectural Glazing Materials, CPSC 16 CFR Part 1201, was developed as a two-tiered standard that went beyond the requirements of ANSI Z97.1, and became law in 1977. ANSI Z97.1 has since been revised to include three levels of impact-resistance – Category A (similar to CPSC 16 CFR 1201 Category II), Category B (similar to Category I), and Category C (the original Z97.1 standard with no equivalent in the CPSC standard). CPSC 16 CFR 1201 Category II and ANSI Z97.1 Category A provide the highest level of impact-resistance required by the safety glazing standards – the category required depends on the size and location of the glazing. ANSI Z97.1 Category C does not protect against human impact except for very young children, and is no longer allowed by the IBC where safety glazing is required.

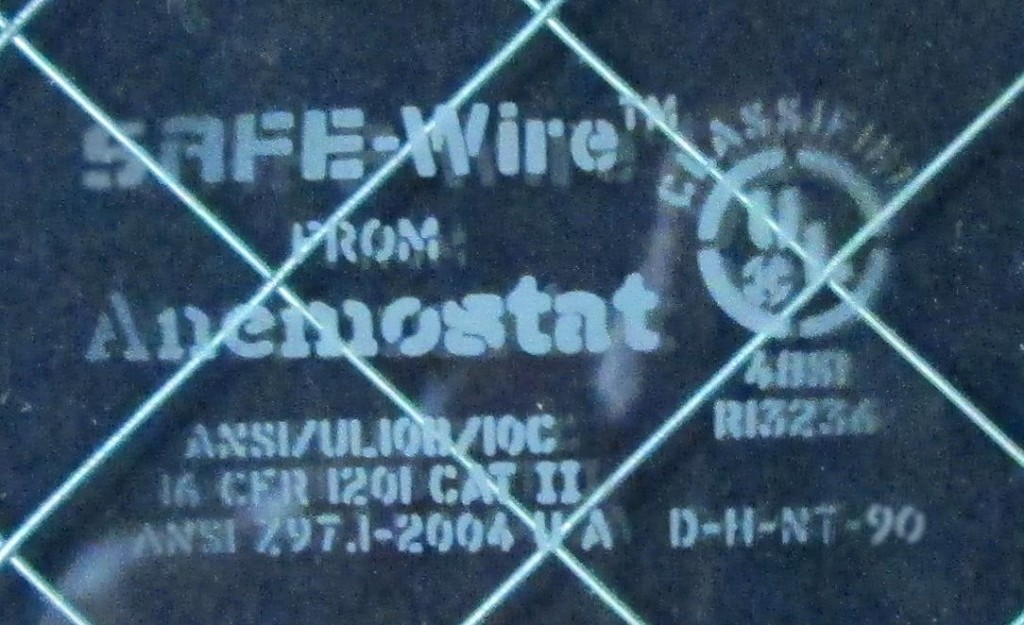

Each piece of glass installed in a hazardous location is required to be marked with information about the manufacturer, glass type, and impact-resistance, as well as the fire-resistance if applicable. Photo courtesy of Anemostat.

Code Changes

When the CPSC standard was created, there were no glazing products that met the impact-resistance and fire-resistance requirements. Traditional wired glass would withstand fire testing, including the hose stream test, but would not withstand the impacts required by the new standard. In 1977, a 2 ½-year exemption was granted for wired glass in fire door assemblies, to give the glass industry time to develop glazing which met both fire and impact requirements. A court battle between the Japanese wired glass manufacturers and the CPSC ensued, and the CPSC was forced to abandon its efforts to regulate the product.

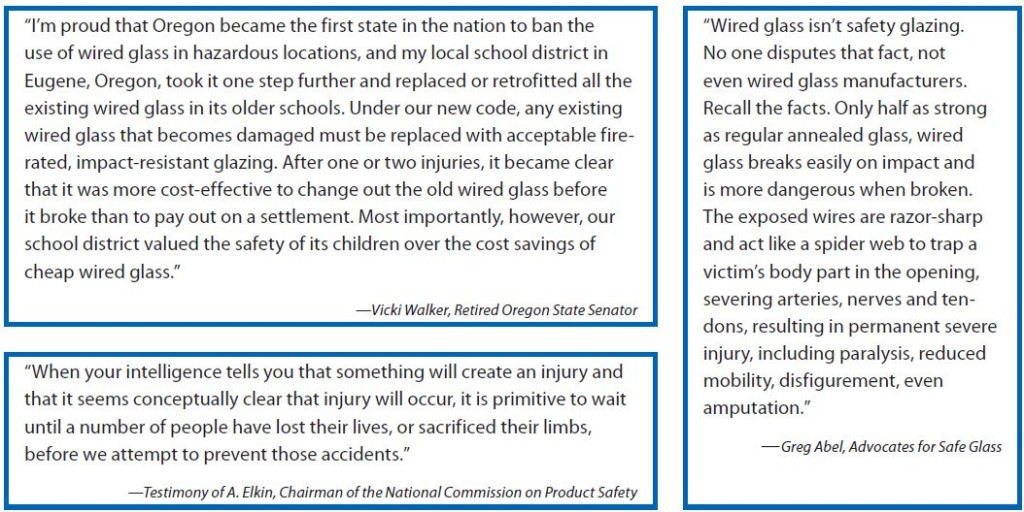

More than 20 years later, the 2000 edition of the International Building Code (as well as the model codes prior) still contained the exception which allowed traditional wired glass in fire door assemblies, even though glazing materials had been developed which were able to withstand both fire and impact. Due in large part to Greg Abel, the father of a young adult who had been injured by putting his hand through wired glass in a door, the 2003 edition of the IBC was changed and traditional wired glass was no longer allowed in any doors or other hazardous locations in Educational occupancies (K-12 schools and day care centers). The 2006 edition of the IBC removed the exception completely, and traditional wired glass is no longer allowed in hazardous locations in any occupancy type when a jurisdiction has adopted this edition of the code. Unfortunately, not everyone is aware of this change, and traditional wired glass is still sometimes supplied for new buildings.

The 2003 edition of the IBC also expanded the section addressing Glazing in Athletic Facilities. In these facilities, glazing which forms whole or partial wall sections, or which is used as a door or part of a door, must comply with the safety glazing requirements listed – CPSC 16 CFR, Part 1201, Category II, or ANSI Z97.1 Category A. In effect, this section mandates impact-resistant glazing in all gymnasiums, basketball courts, and other athletic facilities.

All of the doors and sidelites, as well as many windows in this university dormitory, contain traditional wired glass in a “chicken wire” pattern. The piece of wired glass on the left is in an exterior window. Many of the existing pieces with this pattern have been broken and replaced with traditional wired glass in a square or diamond pattern.

Hazardous Locations

According to the IBC, hazardous locations are those that are most prone to impact from a building occupant. In terms of doors, safety glazing is required for the following hazardous locations:

- Glass in ALL* swinging, sliding, and bifold doors and panels, except jalousies (the type of door with a lite made from horizontal slats). *The exception to this is lites in doors where a 3” diameter sphere cannot pass through the exposed opening – this would not be considered a hazardous location.

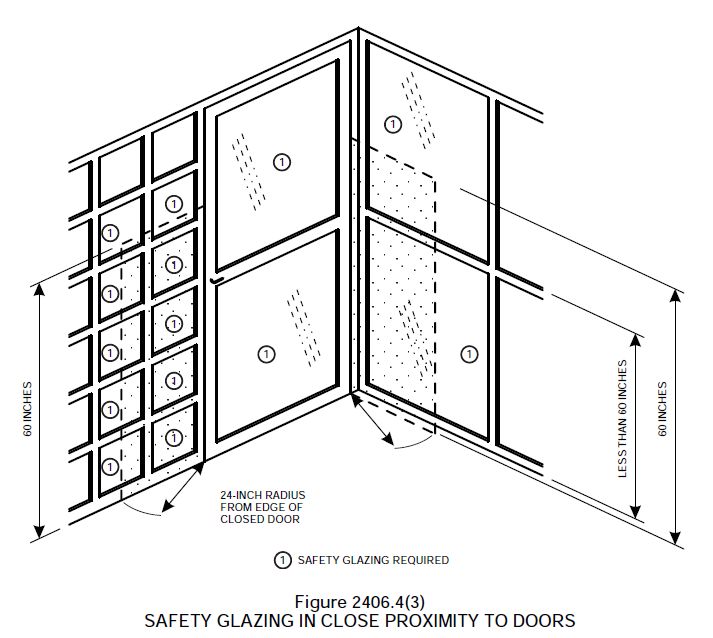

- Sidelites or fixed or operable panels located with the nearest exposed edge of the glazing within a 24-inch arc of either vertical edge of the door and with the bottom exposed edge of the glazing less than 60 inches above the walking surface (refer to the IBC for exceptions).

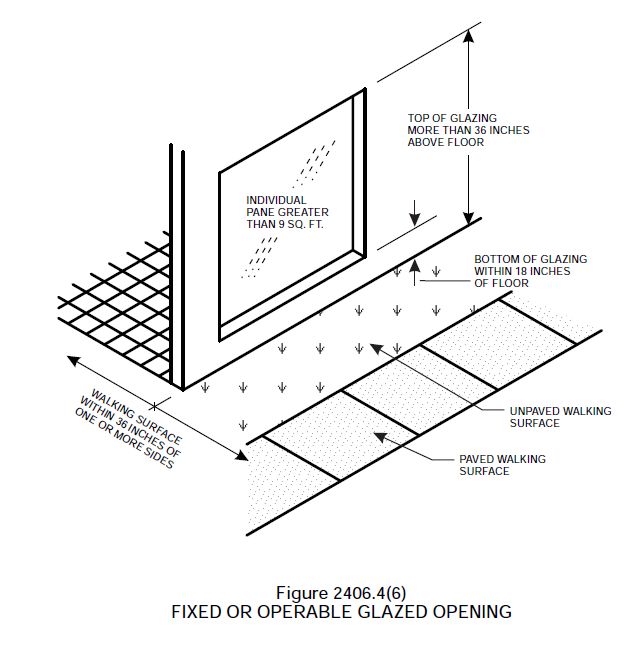

- Fixed or operable panels meeting ALL of the following conditions: Exposed area of an individual pane more than 9 square feet, with the exposed bottom edge less than 18 inches above the floor and the exposed top edge more than 36 inches above the floor, and a walking surface within 36 inches horizontally of the glazing (refer to the IBC for exceptions related to a protective bar or insulated glass).

In addition, safety glazing is required in many instances when in close proximity to wet surfaces (pools, hot tubs, showers, saunas, etc.), in guards and railings, or when adjacent to stairways, landings, and ramps. The requirements depend on the location of the glass, particularly the height above the walking surface.

Each pane of safety glazing installed in hazardous locations must have a permanent identification mark which includes the manufacturer’s designation, the safety glazing standard with which the product complies, and the type and thickness of the glazing. It also includes information about the fire resistance characteristics of the glazing if applicable. Look for the CPSC 16 CFR 1201 or ANSI Z97.1 designations on the etching or label on the glass to determine if meets the requirements for impact.

Diagrams from the 2009 IBC Commentary:

Existing Glass

The changes to the building codes will help ensure that glazing in new schools will be safe, but what about the millions of pieces of traditional wired glass in existing doors, sidelites, and windows? There is wired glass on the market today which meets the current code requirements for impact-resistance, but the vast majority of wired glass installed in existing buildings does not. Many schools have already begun to evaluate their existing wired glass, and prioritize the glazing for replacement or the application of a safety film that will increase the impact-resistance. A suggested list of wired glass locations that should be reviewed, starting with those most prone to human impact includes:

1) Athletic facilities, gymnasiums, basketball courts

2) Doors and sidelites which are not fire rated – traditional wired glass has not been allowed by code in these locations for decades

3) Doors where the glass is behind or directly adjacent to the hardware, where impact is likely – especially high traffic doors with door closers

4) Sidelites and large windows

5) Fire doors with smaller glass lites not adjacent to the hardware – these locations carry the lowest risk of injury

While we must do our best to protect students from intruders, fire, and other hazards that they may encounter at school, we also need to consider the potential for injuries caused by traditional wired glass. In the interest of security, many schools are now considering the replacement of existing glass with products that will withstand force entry tactics. In addition, all of the wired glass should be evaluated, and replaced or remediated as soon as feasible.

I would like to thank Greg Abel of Advocates for Safe Glass for assisting me with my research and education on wired glass, and for taking the initiative to stand up to the wired glass industry and see these code changes through. His work will undoubtedly protect building occupants from injuries or even fatalities.

You need to login or register to bookmark/favorite this content.

Great article. Unfortunately, I have seen the damage that wire glass can do to a middle school student. A friend of mine put his hand through the wire glass in a door when I was in 6th grade (long before I ever dreamed of getting into this industry). I don’t know how I did it but I somehow had the instinct to prevent him from pulling his arm out. Myself and another friend carefully pulled away the broken glass so he could pull his arm out without causing more damage. However, the damage was already done. It cost him the feeling in some of his fingers that he’ll never get back.

I don’t provide glass very often but I do look for it in the plans and specs and point it out whenever I see wired-glass.

Thanks Eric. Your friend probably has you to thank for preventing even worse injuries.

If wired glass is weaker, then why was it installed in the first place? What was the original purpose of wired glass?

When the safety glass standards were put into place, there was no glass available that would meet the impact requirements and the fire-resistance requirements, so a temporary exemption was granted for fire door assemblies. This was back in the late 70’s, and it took until 2003 to start making progress with removing that exception from the codes.