Hal Kelton of DOORDATA Solutions sent me the Fixed-it Friday photo below, and I’m a little curious about why the shoe wasn’t secured to the stop, but surprised that someone would go to the trouble to cut four closer shoes to make a shim. That’s a pretty expensive shim!

sent me the Fixed-it Friday photo below, and I’m a little curious about why the shoe wasn’t secured to the stop, but surprised that someone would go to the trouble to cut four closer shoes to make a shim. That’s a pretty expensive shim!

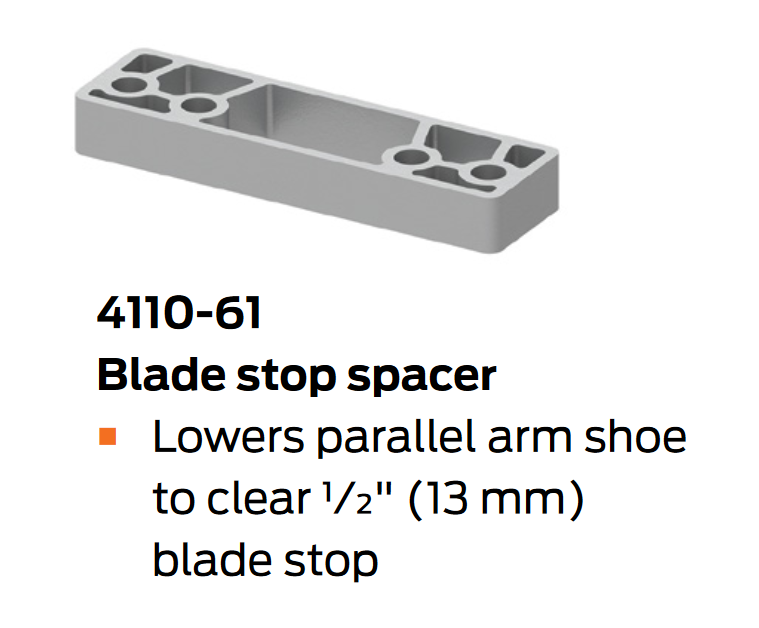

Normally when you see something like this it’s because the frame has a blade stop – there is actually a part that is designed for that purpose. —>

If anyone has a photo of an LCN closer with a blade stop spacer, send it along so I can do a “What’s that?” post!

You need to login or register to bookmark/favorite this content.

ST 5283 – no charge

I know why they made their own shims, Three solid reasons , first is they probably don’t know about the shim. I have been in the business for 45 years and didn’t know. Second I would guess not many wholesalers stock them meaning special order and time it takes to get one. Third is you get to the job and find you need one, I have dozens of parallel arm shoes in stock from installing regular arm or top jamb mount closers. Easy enough to cut and space, but then the holes and shape doesn’t match the plate so they brought it back from the stop. Now, they change the geometry a little and mess with where latch cycle of the closer is at by bringing it back but probably not enough to matter. This afternoon I installed a 4040XP on an aluminum storefront door and brought the shoe back a little to miss the edge of the aluminum stop. And yes I used the black plastic part most installers throw away. The smart guys (I had to ask many years ago) know it is the fifth hole spacer block.

Shims look to be cut from non EDA shoes where the closer they came with were installed on the pull side in Regular arm configuration. A step up from being used as a 10 hour hold open wedge.