Although my role as Manager, Codes & Resources for Allegion focuses on the model codes and referenced standards widely used in the United States, I periodically receive questions about European standards. Because iDigHardware’s international readership is growing, I began sharing information from our international team a few months ago.

Although my role as Manager, Codes & Resources for Allegion focuses on the model codes and referenced standards widely used in the United States, I periodically receive questions about European standards. Because iDigHardware’s international readership is growing, I began sharing information from our international team a few months ago.

When I was at the DHI conNextions Conference in Boston, I met Sushil Kumar, who has written some of these posts for our international audience. Sushil is the Specification Writing Team Lead in Allegion’s Bangalore, India office. I told Sushil I had heard that Allegion employees who visit our Bangalore team are taken home to someone’s mom or grandma’s house for dinner, and he said that could absolutely be arranged! Of course, I’m hoping to do some code training there in the near future! 🙂

The information below is the first post in a series on the EN standards for hardware, and was sent by Hamza Ali DHT and Sushil Kumar Dip GAI, both of Allegion.

~~~

In North America we have ANSI/BHMA standards which confirm the size, quality, material, etc., for the door hardware products. Similarly in Europe and UK we have EN classifications for the door hardware (Ironmongery). This standard and classification guarantees that the products meet a certain criterion with regards to cycle test, load bearing capacity, corrosion resistance etc. We would like to bring to the notice of architects and contractors to look for products which conform to and bear the EN Classification for durability and performance of the product on their projects.

BS EN 1935 Single-Axis Hinges

This standard provides details on product types, classification by use, test cycles, door mass, and corrosion resistance, as well as definitions, product performance requirements, test apparatus, test methods and marking of products. NOTE: This standard has replaced BS 7352:1990: Specification for strength and durability performance of metal hinges for side hanging applications and dimensional requirements for template drilled hinges.

Classifications

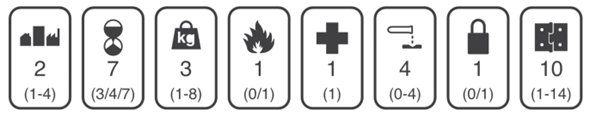

BS EN 1935 classifies door furniture by using an 8-digit coding system. A similar classification applies to all building hardware product standards so that complementary items of hardware can be specified to, for instance, a common level of corrosion resistance, category of use, etc. Each digit refers to a particular feature of the product measured against the standard’s performance requirements.

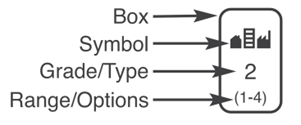

DHF (Door Hardware Federation, UK) has a recommendation to use the graphic icons to enhance clarity of information and has devised a system to facilitate assimilation of the various product classifications. Each feature within the product classification is represented by an icon comprising four elements; Symbol, Grade/Type, Range/Options and Box.

The icon above is for a product which meets Grade 2 in the Category of Use classification, where EN 1935 stipulates a range of four possible grades from 1 to 4.

.

![]() Digit 1 – Category of Use

Digit 1 – Category of Use

Four categories of use are identified:

- Grade 1: Light duty

- Grade 2: Medium duty

- Grade 3: Heavy duty

- Grade 4: Severe duty

.

![]() Digit 2 – Durability

Digit 2 – Durability

Three grades are identified for single-axis hinges manufactured to this European standard:

- Grade 3: 10 000 test cycles, for light duty hinges on windows only

- Grade 4: 25 000 test cycles, for light duty hinges on windows and doors

- Grade 7: 200 000 test cycles, for medium. heavy and severe duty

- Hinges on doors only

.

![]() Digit 3 – Test Door Mass

Digit 3 – Test Door Mass

Eight door mass grades related to single-axis hinges are identified in this European standard as shown in Table 1 below.

| Test Door Mass Grade | Door Mass |

| 0 | 10 kg |

| 1 | 20 kg |

| 2 | 40 kg |

| 3 | 60 kg |

| 4 | 80 kg |

| 5 | 100 kg |

| 6 | 120 kg |

| 7 | 160 kg |

.

Digit 4 – Suitability for fire/smoke door use

Digit 4 – Suitability for fire/smoke door use

Two grades of suitability are identified for single-axis hinges:

- Grade 0: Not suitable for fire/smoke resistant door assemblies

- Grade 1: Suitable for fire/smoke resistant door assemblies

subject to satisfactory assessment of the contribution of the single-axis hinge to the fire resistance of the specified fire/ smoke door assemblies. Such assessment is beyond the scope of this European standard (details in EN 1634-1).

.

![]() Digit 5 – Safety

Digit 5 – Safety

Single-axis hinges are required to satisfy the essential requirements of

safety in use. Therefore, only grade 1 is identified.

.

![]() Digit 6 – Corrosion Resistance

Digit 6 – Corrosion Resistance

Five grades of corrosion resistance are identified in accordance with EN 1670:

- Grade 0: No defined corrosion resistance

- Grade 1: Mild resistance

- Grade 2: Moderate resistance

- Grade 3: High resistance

- Grade 4: Very high resistance

.

![]() Digit 7 – Security

Digit 7 – Security

Two grades of security are identified for single-axis hinges:

- Grade 0: Not suitable for use on burglar-resistant door assemblies.

- Grade 1: Suitable for applications requiring a degree of security. Annex C of this European standard details the hinge grade to use for the level of security required.

.

![]() Digit 8 – Hinge Grade

Digit 8 – Hinge Grade

Fourteen grades are identified in this European standard and are detailed in Table 2 below. The full classification is shown in the standard.

| Hinge Grade | Usage | Test Cycles | Door Mass |

| 1 | Window | 10,000 | 10 kg |

| 2 | Window | 10,000 | 20 kg |

| 3 | Window/Door | 25,000 | 20 kg |

| 4 | Door | 200,000 | 20 kg |

| 5 | Window | 10,000 | 40 kg |

| 6 | Window/Door | 25,000 | 40 kg |

| 7 | Door | 200,000 | 40 kg |

| 8 | Window | 10,000 | 60 kg |

| 9 | Window/Door | 25,000 | 60 kg |

| 10 | Door | 200,000 | 60 kg |

| 11 | Door | 200,000 | 80 kg |

| 12 | Door | 200,000 | 100 kg |

| 13 | Door | 200,000 | 120 kg |

| 14 | Door | 200,000 | 160 kg |

.

Example:

The following marking denotes a single-axis hinge for use in medium duty situations, tested to 200,000 cycles, for use on doors with a mass up to 60 kg, with stated fire door suitability, satisfying the essential requirement of safety in use, high corrosion resistance, suitable for burglar-resistant doors, and with a hinge grading of 10.

.

Below is the example from Briton Hinge UK with its EN Classification and markings:

You need to login or register to bookmark/favorite this content.

Minimum Hinge size for Fire Rated door under BS / EN Standard??

it is 4” x 3” x 3mm.

Can’t use this size under ANSI/BHMA.

Nice

An article on panic hardware would be interesting

Coming soon!

Found this very interesting – look forward to additional posts on the European & UK standards.

One never knows where life may lead you….

Ain’t that the truth, my friend?!

– Lori