Over the years, I’ve had several projects where the specifications called for thermal-break frames, polyurethane core doors, or thermal-break thresholds, but the demand has been very inconsistent. The purpose of these products is to reduce the transfer of exterior heat or cold into a building, to lower costs and improve comfort. I’ve often wondered why they weren’t specified more often for exterior openings – particularly in locations with high fluctuations in temperature.

Over the years, I’ve had several projects where the specifications called for thermal-break frames, polyurethane core doors, or thermal-break thresholds, but the demand has been very inconsistent. The purpose of these products is to reduce the transfer of exterior heat or cold into a building, to lower costs and improve comfort. I’ve often wondered why they weren’t specified more often for exterior openings – particularly in locations with high fluctuations in temperature.

I’m doing some research on this topic, in an attempt to pull together clear, concise, (correct, + complete) information about when, where, and why these products should be used. The demand seems to be on the increase, so I’m trying to find out what all of the driving factors are, as well as other considerations for energy efficiency – like the required U-value and/or R-value, and limitations on holding open exterior doors or requirements for vestibules to reduce air transfer.

What drives the need for thermal-break frames and similar products in your jurisdiction? Is it an energy code, another code or standard, LEED/green certification, or a desire to improve energy efficiency? If you’ve seen any helpful articles on this topic, please include a link in the reply box!

WWYD?

You need to login or register to bookmark/favorite this content.

In a building where literally every system in the envelope is being examined and modeled for its energy performance, unbroken hollow-metal systems are a clear weak point. If we have just a couple stair doors, we can work around them, and most of my projects do. But our awareness that we can get thermally broken aluminum systems could simply have us scratching our heads and wondering why we put up with unbroken hollow metal frames for so long. I expect that if the upcharge is small we’ll see thermally-broken frames become the norm even in California, where we have had the luxury of being pretty thermally complacent until recently.

(Put me in the “energy efficiency” and “California energy code” categories, please.)

I agree with Vivian above. Even basic energy code compliance is refocusing designers’ attention on the systems we have just sort of put up with in the past. Even in a southern US state with one of the less aggressive energy codes, the other, larger energy efficiency pushes are getting people to focus on minor details they would have otherwise let slide, even if not specifically mandated to do so.

I’ve been using thermal-break HM frames on all my projects. The problem lies with the antiquated thought process of people in the field. (Sorry GC’s). I would say that 50% of our projects, with masonry construction, end up with the frames being grout filled, thus severely limiting the ability of these frames to prevent thermo-transfer.

I have stared to call these out as spray-foam filled which at least alerts them to something special going on here.

The State of Washington adopted an energy code in 2012 (?). Ironically, there hasn’t been much of an increase in thermo break frames or urethane cores due to a lack of enforcement.

With the Steelcraft thermal break frames being so much more expensive than a standard frame or kerfed frame. A list price for an “F” series kerfed 3070 5-3/4″ 3-sided frame is $317.00 ($200.00 for non-kerfed) while an “FT” thermally broken 3070 5-3/4″ 3-sided frame is $963.00. It’s not so surprising that they want to cut back a little.

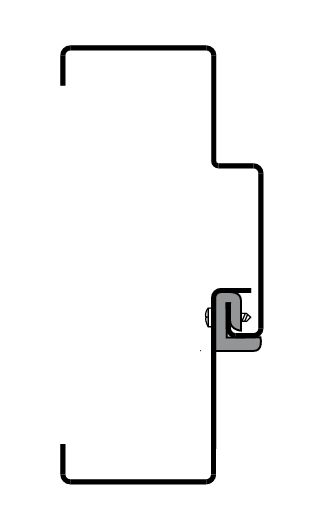

In our Northern region we see thermally broken frames driven by specifications for various reasons but many times it is not always something all parties fully understand the cause and effect and at times something that does not fit well within the project timeline. In addition like Aluminum thermally broken frames Hollow Metal thermally broken material causes many hardware mounting conflicts for stop applied hardware (closers, roller strikes for panics, some weatherstripping, etc.) if trying to avoid penetrating the thermally broken portion of the frame even though any penetration although possible only from multiple screws returns metal to metal contact. The frame also has less rigidity as well which can be a concern for some. The cost difference is substantial not to mention the extended lead-times which many projects simply do not have the time to wait for and we find many end users can benefit greater by using hardware compatible weatherstripping or updating their seal packages to better control the air flow transmission since one weak point in a perimeter seal can be a much larger energy issue than a non-thermal break frame.

Vivian, I agree. Are you seeing this driven by any specific code compliance?

I have yet to be compelled to change hollow metal to thermally broken hollow metal for a project due to energy calculations or prescriptive-method energy requirements.

I would expect to see that happen soon in a project like a school or low-income housing according to the 2017 update to the California energy code. And then I’ll be worrying about all those disadvantages like cost and loss of rigidity.

The more expensive projects will be using energy models, and will probably keep on making up for the few hollow metal doors in those projects with improved performance elsewhere.

I’m mildly surprised that my project that wants to approach net-zero energy hasn’t asked for higher-performing hollow metal – I should probably ask them! But that wouldn’t be a code requirement, it would be an ambition to beat the code by more than a small percentage.

Lori:

What drives this is the government required compliance of all new commercial buildings to ASHRAE Standard 90.1. It’s been my experience for the past several years that most AHJ require some form of energy calculation to prove compliance. Comcheck is a web based site that I believe will answer most of your questions. HTTPS//www.energycodes.gov/Comcheck

Lori, I have seen a bigger push for this requirement. The requests I have seen came from the architect. This wasn’t code driven or LEED drivenm but as Vivian says above, a desire for better energy efficiency.

I’ve had two projects just recently both calling for the latest and greatest spec of exterior HM openings with an R-value of 3.4 under ASTM C1363. One was looking for all manner of LEED credits, the other had no LEED requirements that I know of.

Both projects are in Chicago – I am surprised more specs do not call for thermal break materials on exterior doors in the area considering the weather, but it is very rare.

I’m seeing it more frequently in NC. I believe it’s driven by the energy code here. The last two projects I handled had 2-1/4″ and 2-3/4″ thick aluminum doors. If you’re providing hardware for aluminum doors provided by others, be sure you get ALL of the door and frame details before ordering your hardware. The thermal-breaks are usually offset to one side of the door. That means the lock must be engineered to accommodate the offset. Also, if you have a narrow backset lock like some of the Adams Rite products, the extrusion inside the door could create some problems. Be careful.

Lori. We are always looking for ways to make the buildings more energy efficient. Owners expect this as well. Another important consideration is to reduce or eliminate frost and condensation on the interior side of the frame which can cause damage to interior finishes. We typically specify thermal break frames like the Steelcraft FT Series for exterior hollow metal frames. We also call out to fill the frames with mineral wool insulation – no grout.

This is a helpful strategy, and makes sense to me. Thank you!

Here in Michigan one factor is the manufacturer/independent representative writing a particular product that eliminates the competition due to product/cost advantage. Most specs in this part of the country are provided by the manufacturer or independent rep.

With the extra cost of a thermally broken frame, the payback is not worth the investment. Our clients would be much better served with better continuous insulation systems and eliminating air leakage from their buildings.

We see this more and more, but we have also had instances where the exterior openings are spec’d to be fire rated and thermal-break. A Mexican stand-off? Nope! Fire rating and standard profile wins every time.

I am coming to this party LATE!

I was wondering if anyone has any spec info on where / when these are typically needed. Living in the Pac NW we dont see drastic temperature variations like the NE or SW. We are starting to see more and more of thermal break and I want to help educate the customer with a little deeper dive. I have reached out to a couple of our manufacturing partners and haven’t been satisfied with the very generic info the sales teams provide.

Jared, Hang-on because this is going to be more “generic” info.

I teach nationally for DHI and in one of the classes I teach we take a pretty deep dive into Hollow Metal doors and frame and even cover Thermal break. It seems to me that this is primarily used in extreme cold climates (Alaska and Canada)….I don’t see or hear of it used much in the lower 48.