This is an actual problem on a current project, and I’m hoping some of you will have ideas to help out. The doors and a portion of the hardware have already been installed, and the remaining hardware is on-site. It’s a double-egress pair in a health-care facility, and it is equipped with a system to prevent patients with Alzheimer’s Disease or other conditions from “eloping”. There is a sensor in the vicinity of the doors which detects an approaching occupant wearing a transmitter bracelet, and when an occupant is detected the system automatically arms the delayed egress locks, which prevent the patient from leaving the unit before staff members can arrive.

The problem with these doors is too much hardware trying to occupy the same space at the top of the opening:

The problem with these doors is too much hardware trying to occupy the same space at the top of the opening:

- 2 exit devices (fire-rated), with electric latch retraction and request-to-exit switches – latches project upon fire alarm

- 2 delayed egress mag-locks (Schlage M490DE) mounted on the push side of each door

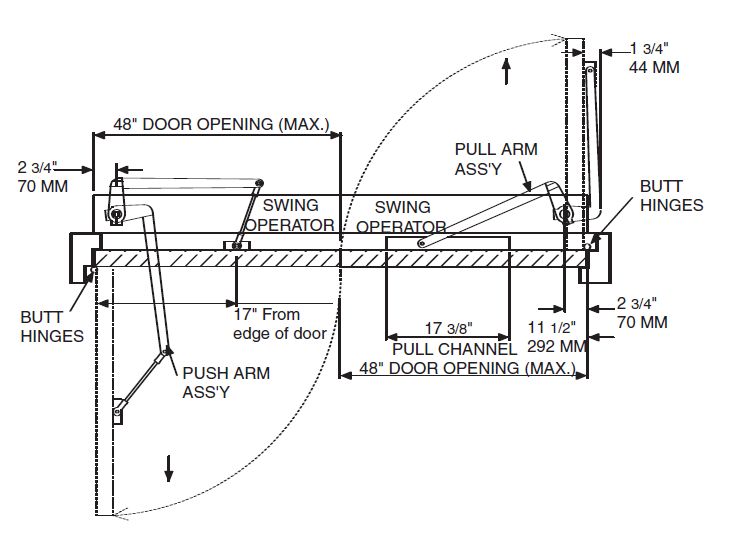

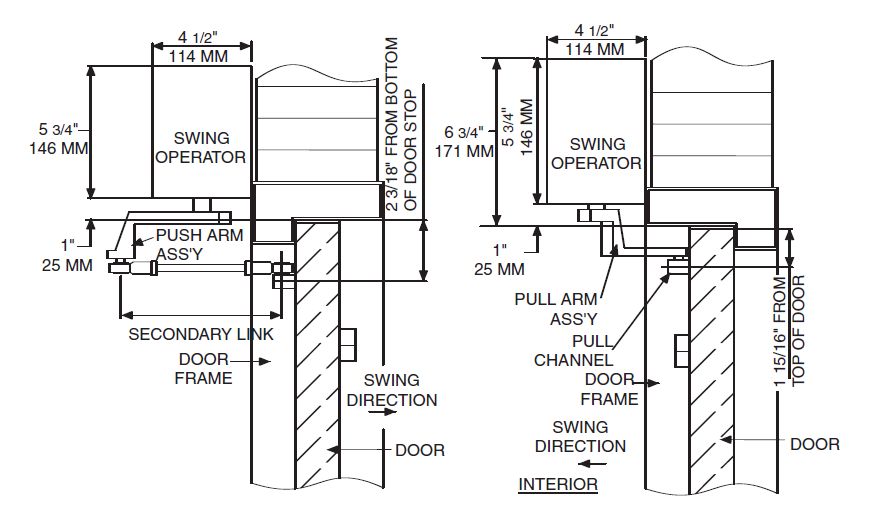

- 1 automatic operator for the pair (LCN 9550 series) mounted on one side of the opening – 1 push, 1 pull

Because the auto operator is mounted on one side of the opening controlling both doors, it creates a conflict with one of the electromagnetic locks. The Schlage M490DE has to mount on the push side of each door, and can not be mounted on the pull side.

I know this post is enough to make most peoples’ head swim, but I’m also positive that some of you know exactly what I’m describing. The obvious objective is to rectify the situation while replacing minimal hardware components and leaving few or no holes to fill.

So, what would you do?

You need to login or register to bookmark/favorite this content.

Use 2 standard magnets and the DE5101.

Great minds think alike! That was my suggestion!

Do both doors need to be DE? Looking above at the first drawing is the PIR on the non secure side? In theory you are just trying to hold patients back on one side? So you would only need 1 leaf to be DE. The other could be simple traffic control but tied to the fire alarm. If I’m seeing this right and I could be all wrong (it happens a lot) you could then switch to another style of mag lock which can be mounted pull side….look at Dyna lock they have some inswinging bracket solutions.

Next time you might consider a “contra swing” solution, this allows egress both directions but changes how you latch the doors. How did you draw the lucky short straw for this one?

This wasn’t one of mine (luckily!), I’m just trying to help out with some suggestions. I asked if both doors need delayed egress but I will double-check. They looked at the Dynalock inswinging DE lock but apparently it’s not UL listed.

Mount 2 single operators on the pill side. Just be sure the operator is mounted securely

That was one suggestion but I think the operators are already installed so they’re looking for the least expensive fix.

Are you using 9927 or 9947 exit devices

They’re another brand but they are surface-mounted.

My suggestion would be EL-RX SVR LBR Rated devices with an external delayed egress controller. The EL devices could always be powered and wired to trip on fire. The REX works independently of this and could be used to trigger the external delayed egress controller. Use smaller mag locks to aid in the installation with all the other hardware on the doors. You can use both of the mags on the push side of the doors so you will not need any build out fillers for the inset frame.

Thanks Jon.

What am I missing? Oh yeah. What is opening width?

Is this a pair of 3′ doors?

Doing the math, I am seeing a conflict on a 36″ wide door, but only on the door that the auto operator is pushing.

Anything over that, and all is good.

Might be a slight problem with the far end through bolt for the pull side auto operator channel, but that is it.

If the doors are truely just for securing the Alzheimer’s patients, then the doors are not required to automatically unlock on a fire alarm activation. Since they are cross-corridor doors, there is a possibility that the doors would not have to latch, unless they serve as an entrance to a suite-of-rooms, or if the doors serve a fire rated barreir, such as a horizontal exit. I like the suggestion from Travis to only install a mag-lock on the egress leaf of the pair, and remove any pull handles from the other leaf.

I would not go the route of delayed-egress locks as it really does not provide the security for wandering patients that the organization would like. And, the entire building needs to be fully sprinklered in order to use delayed egress locks.

Another consideration is to eliminate entirely the automatic operator and go with a simple door closure and magnetic hold-open device. You can make the door hold-open device release after 30 seconds so the door is not accidentally left open.

I would have to think there are other means to secure the door if the organization wanted to continue to use the automatic operator.

Thanks Brad.

Didn’t you have a photo not not long ago showing one maglock holding two doors?

Yes, but that wouldn’t work for double egress pairs.

I would lean towards switching the magnetic locks. Since they appear to be the components not yet installed. I agree that in retrospect concealed devices and shear mags and/or another auto-opener configuration would be best, but anyone can come in after the fact.

I would make careful consideration of the previous comment on whether both leaves need the delayed feature, and if so then the supplementary delay and two other mags may fit the best option, My advice to the enduser/architect is that you will not and cannot use hardware to administrate – so policies should be in place for monitoring, and if they have something like the old Jeffery System, then they can use presence locators to signal alarms as well, so if someone gets on the wrong side of the doors, then they would trigger an alert.

Double Egress doors are a catagory of doors that often generate problems not by virtue of being double egress, but by the design professional using the wrong doors for the application. I agree with the previous respondant that it is not clear why they have the double egress requirement. I guess the only thing they could have done worse would be to need one of the doors to go 180 degrees had it been drawn as such – i’ve had that bundle of joy a couple of times, but my real joy was seeing the best solution so quickly posted, my compliments to Ms. Stewart and the others above.,

Thanks Kevin! I agree, I haven’t seen anyone come up with a reason yet that the DE5101 solution won’t work.

I would think two delayed egress exit device that could be shunted with valid credentials would eliminate the need for the Mag.

If that is not acceptable use one exit coming into the controlled space with an electrified trim. I do not see the need for mags in this application.

The DE coming into the controlled space could be turned on by the presence of the tenant that is be controlled through any number of systems. This would allow free ingress to the space and only controlling egress out.

How about this if it hasn’t already been mentioned:

1) Door Position Switch Hinges.

2) Shear locks, mounted right next to the CVR preps, top of doors. May not get full holding force but considering the application you may not need it.

Hi Lori, I would like to ask about the meeting stile models that are appropriate for 3 hr double egress door. Thanks

Hi Mike –

What type of product for the meeting stiles do you need help with?

– Lori

Hi Lori, I have an opening that requires 3 hr double egress door. The meeting stile edge of the HM door is parallel bevel type.

1- Is it required to specify meeting stile astragal for this door? If yes what type shall apply?

2- If the door is smoke barrier, what type of smoke seal shall be specified for the meeting stile edge?

Thanks,

Hi Mike –

Sorry for the delay – I’ve been traveling this week. The codes do not dictate whether you’ll need an astragal – it will depend on what the door manufacturer has tested. Typically we do see astragals on 3-hour doors. I checked the UL listing for Steelcraft, and all of the 3-hour doors are shown with astragals (http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpage.html?name=GSYX.R3993&ccnshorttitle=Swinging-type+Fire+Doors&objid=1074293926&cfgid=1073741824&version=versionless&parent_id=1073987497&sequence=1). This could be a flat steel astragal overlaIpping from one door to the other. If the door is located in a corridor or smoke barrier the IBC requires the opening to be able to limit air infiltration per UL 1784. I checked with someone from a weatherstrip company and we are in agreement that an overlapping steel astragal installed so that it will contact the door, will provide enough of a seal to limit smoke. You will also need perimeter smokeseal at the head and jambs.

– Lori

Thanks Lori for these information. I really appreciate it.

Mike

I am a construction professional working for a general contractor, though not a door hardware expert. I came across this post while trying to gain a better understanding of the functions of a request-to-exit switch. In this application, do I understand correctly that the exit devices’ latches are normally retracted and project upon activation of the fire alarm because the mag lock normally keeps the door locked when the DE is armed, and upon activation of the fire alarm, the mag lock fails safe and the latches project to provide positive latching and avoid the doors from swinging freely?

Hi Elan –

An RX switch can serve different purposes. I read this very old post and I’m thinking the RX switches may have been interfacing with the security system. I can’t think of why they would be needed for the application that I described in the post. They can be used to unlock a mag-lock or activate a delayed egress lock, but that would not have applied to the locks used on this project. If you need help with a particular application, let me know.

– Lori

Thanks so much for your reply, Lori.

You’re welcome!

– Lori