The increased enforcement of the inspection requirements for fire door assemblies has brought some pretty intense scrutiny upon the various components. In some cases we’re finding that NFPA 80 and the model codes don’t currently address the fine details of how these assemblies are tested and constructed.

The increased enforcement of the inspection requirements for fire door assemblies has brought some pretty intense scrutiny upon the various components. In some cases we’re finding that NFPA 80 and the model codes don’t currently address the fine details of how these assemblies are tested and constructed.

I was recently contacted by a facility that had been cited because of open holes in their labeled frames…

Are open slots allowed in the frame head when the frame is welded?

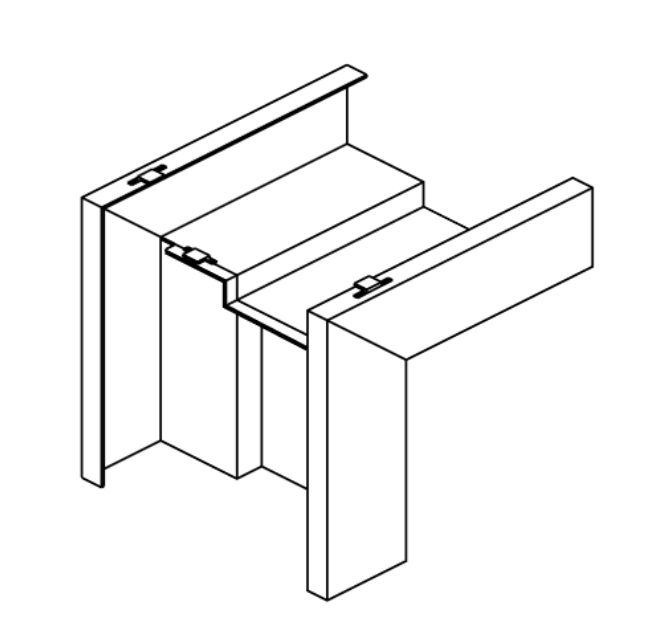

The slots in question are the ones that are used when a KD (knocked down or knock down) frame is field-assembled. Tabs attached to the jabs fit through slots in the head, to attach the 3-sided-frame components together. When the frame is welded, most installation instructions call for the tabs to be bent or broken off – they are not inserted through the slots. This video from Steelcraft shows the tabs being removed (0:52) and the empty slot is visible after the frame is welded (5:08).

This leaves small narrow slots in the top of the frame head that are barely noticeable, but one of the inspection criteria of NFPA 80 is, ” No open holes or breaks exist in surfaces of either the door or frame.” It’s not surprising that fire door inspectors may list these open slots as deficiencies during a fire door inspection.

When a listing lab certifies a component of a fire door assembly, the installation instructions are part of that listing. If the instructions call for the tabs to be broken off during the welding process, and do not require the resulting open slots to be filled, the listing lab is allowing the open slots to remain (I confirmed this with UL). This creates a conflict between what is allowed by the frame manufacturer’s listings and what is required by NFPA 80. I would defer to the listings, as the frames have been successfully tested this way.

Have you run into this situation? How was it addressed?

Graphic: Steel Door Institute (SDI)

You need to login or register to bookmark/favorite this content.

The same is true with the mute (silencer) holes in the stop of the frame. It was tested that way and it does not matter if the mutes are present or not. Other than being noisy or in the case of stick-on weatherstrip being added covering the holes up.

I don’t like the look or appearance of frames like that, but that is my personal opinion and a spec issues in my mind.

As for compliance if the assembly was tested and passed with such holes then it complies.

This also leads me to question for all the people that use single return masonry frames and weld them for drywall applications is that a listed assembly?

Tabs and slots are how the frame meet fire rating. Face welding is not required. Saw miter has to be face and web. So if open slots are present frame is not pre-assembled per lable procedure instructions.

Hi Roger –

If KD frames are welded, the instructions call for the tabs to be broken off or bent out of the way. That would result in the open slots and according to UL this is acceptable.

– Lori

A little education, please. Are the mutes in the stops that Kent Krauser mentioned the locations for the little rubber “buttons”. Are those the mutes?

Hi Dwight –

“Mutes” are also called silencers…they are the rubber bumpers that the door closes against. Usually there are 3 on the strike jamb of a single door frame or 2 on the head of a pair. http://commercial.chown.com/images/product/480/builders/P021054.jpg

– Lori

Hi Lori, we have run into this exact problem at a healthcare facility where our installed doors have open slots on the top. We have received a non compliance for not meeting NFPA 80. What is the best way to get this cleared? Is the documentation that would show that this condition is still in compliance? Thank you!

Hi Chris –

I would ask the frame manufacturer(s) if they can write you a letter stating that the frames are still compliant with their listings. If the frames are from Steelcraft or Republic, send me an email at lori.greene@allegion.com and I’ll see what I can do.

– Lori