If you’ve been following this series about glass, you now know more about the standards for impact-resistance as well as which areas are considered hazardous locations. But when you’re looking at a piece of glass installed in a door, sidelite, or other location where impact-resistance is required, how do you know if the glass is code-compliant?

To re-cap the previous post before we move on to identification, the testing requirements from the Consumer Products Safety Commission (CPSC) and the American National Standards Institute (ANSI) are very similar. Category II from the CPSC standard is equivalent to Category A of the ANSI standard (400 foot-pounds of force), and Category I from the CPSC standard is equivalent to Category B of the ANSI standard (150 foot-pounds of force). They use the same weight and drop height for testing. If your glass says “CPSC 16 CFR 1201 CAT II”, you’re covered for impact-resistance.

There is an additional category within ANSI Z97.1 – Category C (100 foot-pounds of force), which does not comply with the current International Building Code requirements for hazardous locations. Prior to the code changes which began with the 2003 edition (more on that later), glass in fire doors was exempt from the more stringent requirements and was only required to meet the lowest force category (C) of ANSI Z97.1. Glazing in fire doors is no longer exempt, and must be tested in accordance with CPSC 16 CFR 1201 Category II / ANSI Z97.1 Category A, or CPSC 16 CFR 1201 Category I / ANSI Z97.1 Category B, depending on the location and glass size (check the tables on this post).

The test standards don’t require the glazing to withstand the impact – the glass can (and usually does) break. If the glass does not break, it successfully passes the test. If it does break, the glass is evaluated in one of two ways. 1) A 3″ sphere may not pass through the test specimen (the standards vary slightly on the weight of the sphere and the time it is placed on the glass), or 2) Within 5 minutes of the impact, the 10 largest particles of glass are weighed, and must not weigh more than the weight of 10 square inches of the original specimen. There is another method to evaluate glass that comes out of the frame on impact.

Here’s an example of what the drop portion of the test looks like:

And now (finally), identification requirements for safety glazing. Here’s what the 2009 edition of the IBC says about identification:

2406.3 Identification of safety glazing. Except as indicated in Section 2406.3.1, each pane of safety glazing installed in hazardous locations shall be identified by a manufacturer’s designation specifying who applied the designation, the manufacturer or installer and the safety glazing standard with which it complies, as well as the information specified in Section 2403.1. The designation shall be acid etched, sand blasted, ceramic fired, laser etched, embossed or of a type that once applied, cannot be removed without being destroyed. A label as defined in Section 202 and meeting the requirements of this section shall be permitted in lieu of the manufacturer’s designation.

Exceptions:

1. For other than tempered glass, manufacturer’s designations are not required, provided the building official approves the use of a certificate, affidavit or other evidence confirming compliance with this code.

2. Tempered spandrel glass is permitted to be identified by the manufacturer with a removable paper designation.

To summarize the IBC section, each pane of safety glazing installed in hazardous locations must have a permanent identification mark including certain information. Spandrel glass can have a removable paper label instead of a permanent mark. The other option (with prior approval of the AHJ) is for a facility to have a certificate or affidavit certifying that the glass in the facility is code-compliant. I have not seen this exception applied to glazing in doors very often. Although the glass may be code-compliant when it is installed, what if some pieces are replaced over time? And who keeps track of the certificate? The individual marks on the glass are much easier to manage.

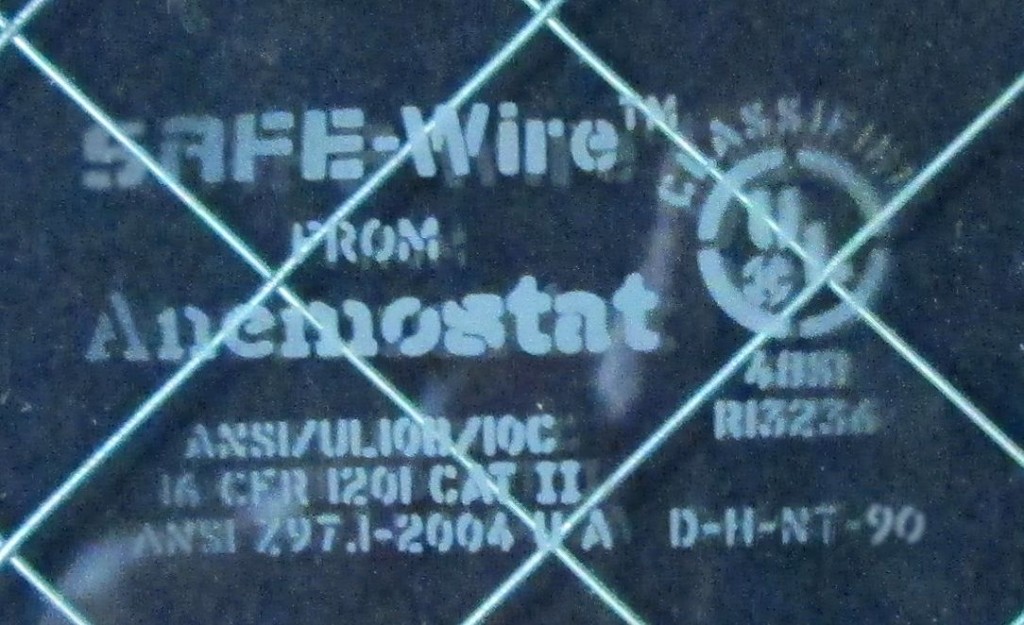

From Ron Hansen of Anemostat, here’s a photo of what the permanent mark looks like. Note that this type of wired glass does meet the impact-resistance requirements – it is marked “16 CFR 1201 CAT II” and “ANSI Z97.1 2004 U A“.

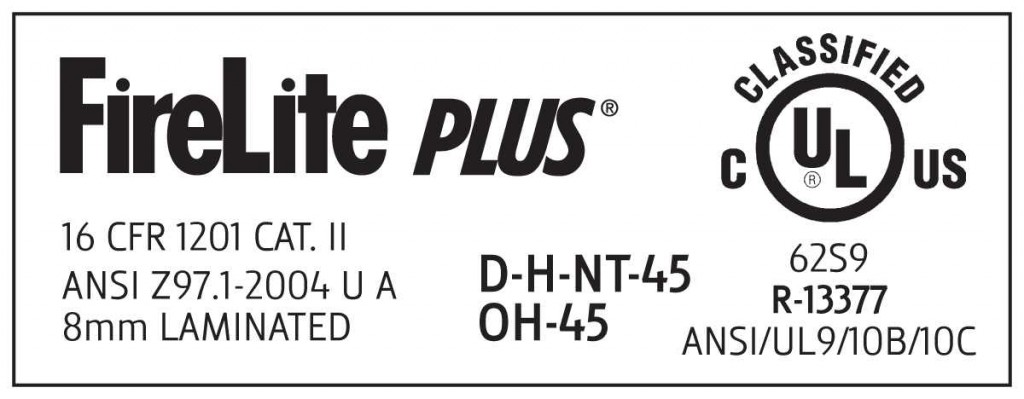

Here’s a label from Technical Glass Products that we can take a closer look at:

Per IBC requirements, the label/etching includes the following:

- Manufacturer’s designation (FireLite Plus)

- Safety glazing standard with which the product complies (16 CFR 1201 Cat. II and ANSI Z97.1-2004 U A)

- Type and thickness of the glazing (8mm LAMINATED)

It also includes a wealth of information about the fire resistance characteristics of the glazing. In addition to the UL/ULC mark, and an indication that it has been tested in accordance with UL10B (neutral pressure test) and UL10C (positive pressure test), the series of hyphenated numbers and letters indicate locations where the glass is approved for use, whether it meets the requirements for hose stream and temperature rise, and the fire resistance rating in minutes. Here’s a key to the symbols (there’s a great document on the TGP website):

Location: D=doors, O=openings (windows, sidelites, transoms), W=walls (tested per ASTM E119 for radiant heat transfer)

Hose Stream: H=meets the hose stream requirements (required for 45 minutes or more), NH=no hose stream (allowed for 20 minutes only)

Temperature Rise: T=meets requirements for use where temperature rise rating is required, NT=not approved for temperature rise

Minutes: 20, 45, 60, 90, or 180 minutes

Now let’s go back to the SAFE-Wire photo. What does this mark tell you?

UPDATE: A fire inspector asked me to make a cheat sheet so he can take it with him for inspections, so click here to download the Safety Glazing Reference Card! If you print it, cut it out, and fold it twice, it will be the size of a credit card.

You need to login or register to bookmark/favorite this content.

Thanks, !!!!!! where is the cheat sheet to carry around

The Anemostat glass is for a door, meets hose stream test, does not meet temperature rise req, and is listed for 90 minute. UL10B\C

You get a gold star!!

Nice postings and excellent information. One item on labeling with regards to fire rated glazing products, these must be permanently labeled and certificates are not an option. As one reader mentioned on how to identify “old” wire glass that was non-compliant, that is the reason for it — identification and conformance to life safety. The label markings have also been update per the 2009/2010 supplement to the 2009 IBC and the 2012 IBC which makes it simpler. For example if your fire rated glazing is a 45 minute rated and is used in doors, sidelights and has a hose stream rating it would be marked D-H-45-OH-45. Note that NT for non-temperature rise is not used here as the approach is if it doesn’t state it, it does not meet the requirement. The 2012 IBC chart under Chapter 7, section 716 is a good tool for reference.

I like the helpful info you supply for your articles. Best of luck with the following!

Need a new track for sliding doors 16cfr-1201 ANSI2971-1984

i have this same door – do you know who the manufacturer is?

Can I have a picture of a CGI sentential impact glas etching? It’s on ever CGI impact glass on the inside.