In a previous post, I talked about where safety glazing is required, but what IS safety glazing? More from the 2009 IBC:

2406.1.1 Impact test. Except as provided in Sections 2406.1.2 through 2406.1.4, all glazing shall pass the impact test requirements of Section 2406.2.

Note that “all glazing” means “all glazing in hazardous locations.” This includes all glass in swinging and sliding doors as well as many other locations (refer to the previous post for details).

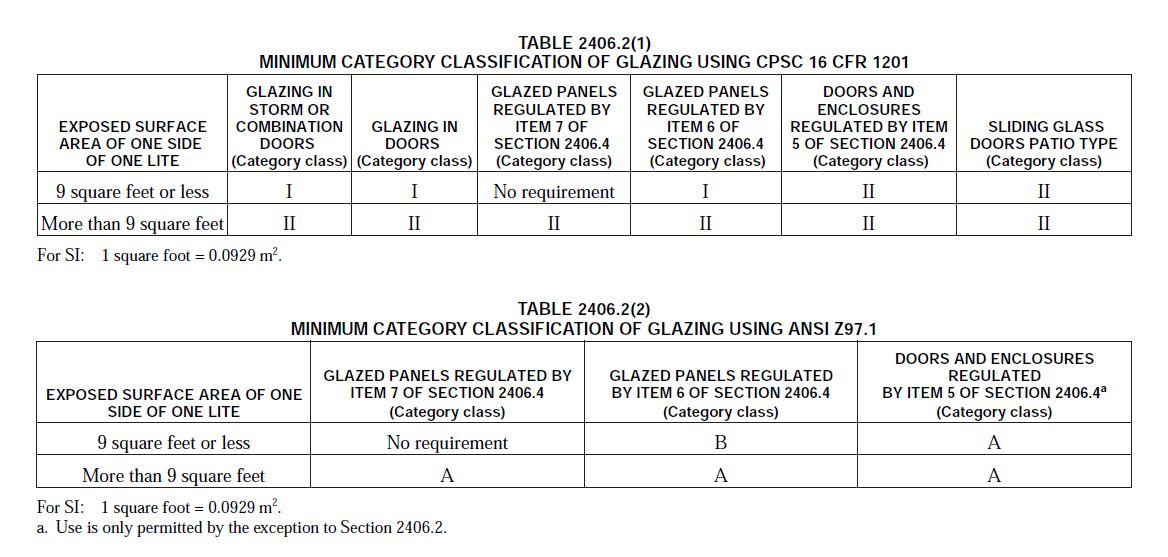

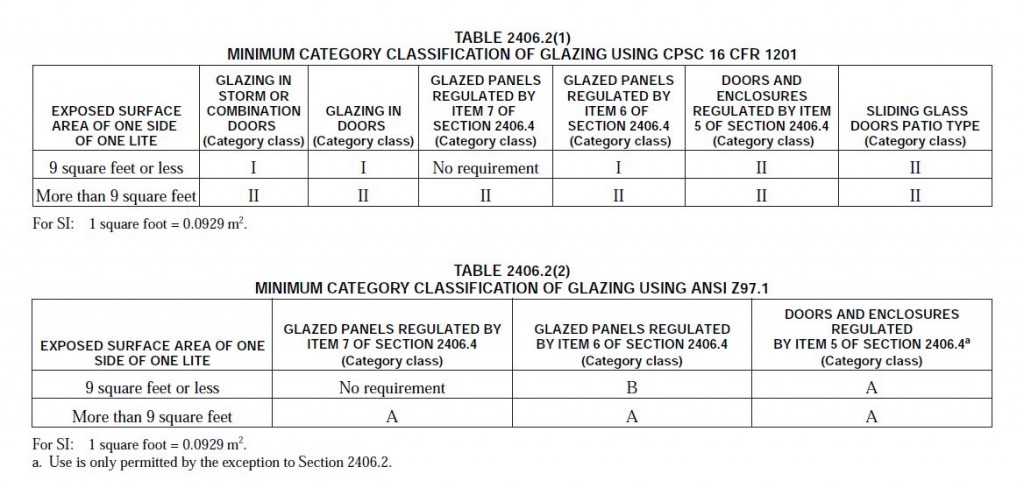

2406.2 Impact test. Where required by other sections of this code, glazing shall be tested in accordance with CPSC 16 CFR 1201. Glazing shall comply with the test criteria for Category I or II as indicated in Table 2406.2 (1).

Exception: Glazing not in doors or enclosures for hot tubs, whirlpools, saunas, steam rooms, bathtubs and showers shall be permitted to be tested in accordance with ANSI Z97.1. Glazing shall comply with the test criteria for Class A or B as indicated in Table 2406.2 (2).

The tables referenced in this section identify whether safety glazing must be Category I or II (CPSC 16 CFR 1201) or Category A or B (ANSI Z97.1). This depends on where the glass is used and the exposed surface area. But what’s the difference? The Glass Association of North America (GANA) has published a detailed comparison of the two standards, and here is some information from that document:

Scope

The principal differences between the CPSC’s 16 CFR 1201 standard and the ANSI Z97.1-2004 standard relate to their scope and function. The CPSC standard is not only a test method and a procedure for determining the safety performance of architectural glazing, but also a federal standard that mandates where and when safety glazing materials must be used in architectural applications and preempts any non-identical state or local standard. In contrast, ANSI Z97.1 is only a voluntary safety performance specification and test method. It does not attempt to declare when and where safety glazing materials must be used, leaving those determinations up to the building codes and to glass and fenestration specifiers.

Application

The CPSC requires the installation of safety glazing materials meeting 16 CFR 1201 only in storm doors, combination doors, entrance-exit doors, sliding patio doors, closet doors, and shower and tub doors and enclosures. Other than that, meeting CPSC’s requirements is necessary only when and if a building code authority or other jurisdiction adopting safety glazing laws specifically mandates that safety glazing comply with the CPSC standard, 16 CFR 1201 — and most building codes do.

ANSI Z97.1, as a voluntary standard, applies only when, where, and if it is adopted by a building code authority or is specified in the approved plans and specifications of the architect, building contractor, or other glass specifier.

The test requirements for both of these standards are very similar – the weight of the bag, the height from which it is dropped, the specifications of the test sample. And to simplify things, most of the glass suppliers I checked show both listings on their impact-resistant glass (examples: Anemostat, TGP). Based on the test standards, CPSC 16 CFR 1201 Category II, and ANSI Z97.1 Category A both require a 100-pound bag dropped from a height of 48 inches (the most difficult category to pass), so if your glass meets this requirement, you’ve got it covered. For locations that don’t require Category II / Category A, other types of glass may be more cost-effective.

To re-cap what we’ve learned so far:

1) Traditional wired glass does not meet the current code requirements for impact-resistance. It is not safety glass, and does not provide more security. It is extremely dangerous and is responsible for more than 2,000 injuries each year IN SCHOOLS.

2) The 2009 International Building Code (IBC) requires glass used in doors, sidelites, and other “hazardous locations” to be impact-resistant. The level of impact-resistance required depends on where the glass is used and the size of the exposed glass.

3) The standards that apply to impact-resistance of safety glazing are CPSC 16 CFR 1201 and ANSI Z97.1. Each standard has categories of impact-resistance, with CPSC 16 CFR 1201 Category II and ANSI Z97.1 Category A providing the highest degree of protection.

What else we’re going to learn:

4) How to decipher the identification marks on the glass to determine whether it is acceptable for use in fire doors and hazardous locations. There IS wired glass that is impact-resistant (although the vast majority of the existing wired glass is NOT), so we need to know how to tell the difference.

5) What the previous editions of the IBC required, and how the code change was accomplished.

6) What does NFPA 101 – The Life Safety Code require in regards to glass.

7) How to address the existing traditional wired glass in schools and other facilities, to prevent injuries.

Anything else you’re wondering about?

You need to login or register to bookmark/favorite this content.

Not sure if this is number four on your list::::

There is wired glass on the market today which meets the current code requirements for impact-resistance, but the vast majority of wired glass installed in existing buildings is not impact-resistant.

Yes! I’ll make sure to cover that!

Is there a date when the improved, impact-resistant wired glass was first introduced to the industry?

What I’m looking for is a cut-off date that would tell you if a particular wired glass was the old, non-safe, style. For example, if the better glass started showing up in 2005, then it would be safe to assume that wired glass installed prior to 2005 is the “bad” glass.

Hi Chuck –

In most cases, glass in doors and other hazardous locations is marked with an etching that includes information about what standards that glass is able to meet – both impact and fire. I’m working on a post about identification for later in the week. If you look at one of your newer pieces of glass, you should see a faint etching in one corner. Wired glass without that etching is probably not impact-resistant, and even if the glass has the etching you have to look at it carefully and understand the codes to know whether it meets current requirements. The IBC requires the etching, but has an exception where the AHJ can accept an affidavit instead, which states that all the glass on the project is code-compliant. This is not typical of wired glass in doors though – it would be more likely to see this done for decorative glass or large expanses of glass.

– Lori

Thank you for the posts on CPSC 16 CFR 1201. Unfortunately, I am still unsure if my product needs to be certified or not. I manufacture a mirror bypass closet door. What is confusing is the fact that our mirror is mounted directly to a solid substrate. My belief is that we still need the testing but if it is a grey area I would like to not have to test.

Hi Vincent –

I think this is what you’re looking for. This is from the 2012 IBC, but there was an exception in another part of the code in prior editions.

2406.1 Human impact loads. Individual glazed areas,

including glass mirrors, in hazardous locations as defined in

Section 2406.4 shall comply with Sections 2406.1.1 through

2406.1.4.

Exception: Mirrors and other glass panels mounted or

hung on a surface that provides a continuous backing support.

It looks to me like your mirrors would be exempt from the impact requirements.

– Lori

Thank you, This was very helpful and exactly what I could not find on my own.

Firstly, Impact rating is great..and the responsibilty of moving away from typ Wire Glass is way over due….Secondly how do we relate impact rating to Loading requirements, especially here in Ontario where we interpret Glass as a Guard.

What I cannot decipher from all of this, as well as the IBC, is which glazing is what. Is laminated glass category I, is tempered glass category II? They describe all of this but when they start specifying what glass goes where its just all about the cpsc 16 cfr 1201 and the categories. Which glass is which?

Thanks for your help.

Does any one know what the etching should say for CGI sentential impact glass?

And what it should look like!

Does anyone know what happened to the page “where safety glazing is required”

and the page (refer to the previous post for details). I really need some information on where impact rated fire glazing is required. =)

Maybe this article will help? https://idighardware.com/2013/04/breaking-tradition-may-2013/

– Lori

why is irc code for stairs different from ibc

Hi Tim –

In what regard?

– Lori