By request, I have updated this article on smoke doors to include the requirements of the 2021 IBC. I know it’s very long, but you don’t have to read and digest the whole thing. When you have a question about a smoke door, just decide which type of smoke door it is (based on the 5 types below) and then refer to the section for that type. And when you need to find this information again, it will be on the Articles page. OR…you can save it in your custom library of posts.

This post was published in Door Security + Safety

It’s hard to believe that my monthly Decoded column has been ongoing since 2010! One of my most frequently-referenced articles was on the smoke door requirements of the 2009 International Building Code (IBC). The IBC has been revised several times since then and I continue to receive questions about smoke doors, so it’s time for an update (I have now updated the article to reflect the 2021 edition of the IBC).

As with previous editions of the code, the reason it’s difficult to determine the requirements for smoke doors is because there are several different sets of provisions that may apply depending on the use group and the wall type where the assemblies will be installed. I used the 2015, 2018, and 2021 editions of the IBC to answer basic questions about each type of smoke door – where they are typically found, and whether the doors require a fire rating, a closer, a latch, and gasketing. The types of smoke doors I identified are:

- Type 1 – Doors required to provide an effective barrier to limit the transfer of smoke

- Type 2 – Doors in smoke partitions

- Type 3 – Doors in smoke barriers

- Type 4 – Fire door assemblies in corridors and smoke barriers

- Type 5 – Doors in exit enclosures and exit passageways

To read about the requirements for a particular smoke door, first determine which of the 5 types applies to the door in question and refer to that section below. Keep in mind that other codes may have different requirements for these doors, so refer to the code and edition that applies to your project’s jurisdiction.

UL 1784 – Air Leakage Tests of Door Assemblies

Gasketing is typically required when a door assembly must limit air infiltration to a maximum value stated in the code when tested in accordance with UL 1784 – Air Leakage Tests of Door Assemblies.

First, a few words on gasketing…Some smoke doors are required to limit air/smoke infiltration to a certain level when tested in accordance with UL 1784 – Air Leakage Tests of Door Assemblies. The maximum amount of air flow allowed by the IBC is 3.0 cubic feet per minute per square foot [0.015424 m3/(s m2)] of door opening at 0.10 inch (24.9 Pa) of water for both the ambient temperature test and the elevated temperature exposure test.

When door assemblies are required to meet this limit, it is difficult or impossible to achieve these values without gasketing at the head, jambs, and meeting stiles. For most doors, a seal at the bottom is not mandated, unless the door is required to meet the stated limits without the artificial bottom seal installed during the test (those locations are shown in this blog post). If the door must be tested without the artificial bottom seal it would typically require a sweep or automatic door bottom – both during the test and on the final assembly installed in the field.

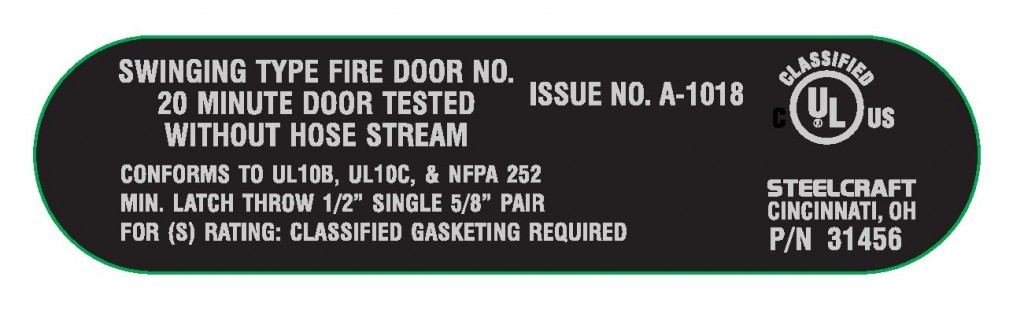

For the purpose of this analysis, doors that have to meet these limits are noted with a requirement for gasketing. These doors will typically have an “S Label” which states that the assembly meets the requirement when classified gasketing is installed. Gasketing manufacturers’ catalogs indicate which products are listed for this purpose. The requirement for testing in accordance with UL 1784 (and the same allowable maximum) is also included in NFPA 105 – Standard for Smoke Door Assemblies and Other Opening Protectives.

~~~

Type 1: Doors required to provide an effective barrier to limit the transfer of smoke

Typical Location: These requirements apply to smoke partition corridor doors in Use Group I-2 (foster care facilities, detoxification facilities, hospitals, nursing homes, psychiatric hospitals). The IBC Commentary states: “this provision is primarily intended to apply to care recipient sleeping room corridor doors,” but it could also apply to other corridor doors that are not part of a vertical opening/exit (stair or shaft), and which do not require a fire rating per Section 509.4 – Separation and Protection for incidental uses.

Some typical examples of doors in health care facilities which are required by Section 509.4 to be fire rated are Group I-2 laboratories, patient rooms equipped with padded surfaces, physical plant maintenance shops, waste and linen collection rooms with large containers, laundry rooms and storage rooms over 100 square feet, and non-sprinklered boiler and furnace rooms which meet certain criteria. These doors and others which require a fire rating must meet a different set of requirements than those addressed in this section – they would typically be either Type 4 or Type 5 below.

For corridor doors required to provide an effective barrier to limit the transfer of smoke:

Fire Rating Required? No. Section 407.3.1 states that corridor doors that are not in a wall that is required to be rated (per Section 509.4 or for the enclosure of a vertical opening or exit) are not required to have a fire protection rating.

Closer Required? No. Section 407.3.1 states that these non-fire-rated corridor doors are not required to be equipped with self-closing or automatic-closing devices.

Latch Required? Yes. Section 407.3.1 states that these doors must have positive latching and that roller latches are not permitted.

Gasketing Required? No. There is no requirement in the IBC for these doors to be tested in accordance with UL 1784 or to limit smoke infiltration to a specific limit. In past editions of the IBC Commentary there was a reference that created some confusion about whether these doors were required to be tested in accordance with UL 1784, but that reference was removed as of the 2015 Commentary.

Note: The 2021 edition of the IBC has added language requiring these doors to be solid doors with close-fitting operational tolerances, and head and jamb stops on the frames. Dutch doors in health care corridor walls must have an astragal, rabbet, or bevel at the meeting edges of the upper and lower sections of the door, with hardware that connects the upper and lower sections to allow them to function as a single door leaf. Both leaves are required to have latching hardware – for egress purposes, the latch on the top leaf typically latches into the bottom leaf and the bottom leaf latches into the frame. This new section of the code also addresses locations where makeup air for exhaust systems is provided in accordance with Section 1020.7, Exception 1, allowing louvers or a clearance of up to 2/3-inch at the bottom of the door.

~~~

The requirement for positive-latching hardware is dependent upon the location of the smoke door. Some types of smoke doors require an active latchbolt; some types do not.

Type 2: Doors in smoke partitions

Typical Location: Section 710 outlines the requirements for smoke partitions including the door openings therein, but there are limited locations within the IBC that currently refer to this section:

- Section 404.6 addresses atrium enclosures, and allows a glass wall forming a smoke partition with automatic sprinklers on both sides of the glass in lieu of a 1-hour fire barrier if certain criteria are met. This section does not refer to section 710, instead it includes the requirements for openings within section 404.6. There is no reference to a requirement for smoke resistance for these doors, even though they are located in a smoke partition.

- Section 407.3 permits corridor walls in Group I-2 to have no fire-resistance rating, but it does require that they be constructed as smoke partitions. The door openings in these walls are covered above, as “Type 1 – Doors required to provide an effective barrier to limit the transfer of smoke,” and will not be addressed again in this section.

- Section 407.4.4.2 requires I-2 care suites to be separated from other portions of the building by smoke partitions complying with section 710.

- Section 3006.3 (2) allows the use of smoke partitions to form the elevator lobby in a sprinklered building, and requires compliance with Section 710. This elevator lobby requirement was found in Chapter 7 in past editions of the IBC.

Fire Rating Required? No. Section 710.3 states that unless required elsewhere in the code, smoke partitions are not required to have a fire-resistance rating. The sections that currently refer to Section 710 do not mandate a fire-resistance rating.

Closer Required? Yes and No. Section 710.5.2.3 in the 2015/2018/2021 IBC states that “Where required elsewhere in the code, doors in smoke partitions shall be self- or automatic-closing by smoke detection in accordance with Section 716.5.9.3.” In the 2018 edition, the reference to Section 716.5.9.3 was changed to 716.2.6.6, the new location of the requirements for smoke-activated doors, and this reference remains the same in the 2021 edition.

- Although Section 404.6 for atrium enclosures does not reference section 710, Section 404.6 does require glass doors within the atrium enclosure wall to be self-closing or automatic-closing.

- Section 407.4.4.2 for I-2 care suites does not include a requirement for self-closing or automatic-closing doors, but additional conditions may apply if the doors are part of a smoke barrier (refer to Type 3).

- Section 710.5.2.3 is specifically referenced in Section 3006.3 (2) for elevator lobbies, therefore, it is “required elsewhere in the code” and elevator lobby doors must be self-closing or automatic-closing.

Latch Required? Yes and No.

- Section 404.6 for atrium enclosures does not reference a requirement for positive latching, although latching hardware may be required to prevent the doors from being pulled open by a smoke evacuation system.

- Section 407.4.4.2 for I-2 care suites does not mention positive latching, although a code official may require these doors to latch because of section 407.3.1 which mandates latches on corridor doors (refer to Type 1).

- Section 3006.3 (2) for elevator lobbies requires compliance with Sections 716.5.9 (2015 edition) / 716.2.6.1 (2018 and 2021 editions), which mandate latching hardware.

Gasketing Required? Yes and No.

- There is no stated requirement for air infiltration limits for atrium enclosures or I-2 care suites.

- For elevator lobby doors, Section 3006.3 (2) requires compliance with section 710.5.2.2. This section references UL 1784 and states the limitation on air infiltration which prompts the need for gasketing. This section also requires the installation of smoke doors to be in accordance with NFPA 105 – Standard for the Installation of Smoke Door Assemblies and Other Opening Protectives and states that louvers are not allowed in doors in smoke partitions.

~~~

Some smoke doors may be either self-closing or automatic-closing, while some locations require automatic-closing doors and others do not require closers at all.

Type 3: Doors in smoke barriers

The following locations addressed in the 2015, 2018, and 2021 editions of the IBC require smoke barriers:

- Sections 405.4.2 and 405.4.3 for Underground Buildings

- Section 407.5 for I-2 occupancies

- Section 408.6 for I-3 occupancies

- Section 420.4 for Group I-1, Condition 2 (Section 420.6 in the 2018 and 2021 editions)

- Section 422.3 for Ambulatory Care Facilities

- Section 1009.6.4 for Areas of Refuge in Accessible Means of Egress

- Section 3007.6.2 for Fire Service Access Elevator Lobby Enclosures

- Section 3008.6.3 for Occupant Evacuation Elevator Lobby Enclosures

Note: The IBC includes exceptions for areas of refuge located within an enclosure for an interior exit stairway and in outdoor facilities where the exit access is essentially open to the outside. Other areas of refuge must be separated from the remainder of the story by a smoke barrier or horizontal exit.

All of these sections require compliance with the provisions of Section 709, with the exception of those related to elevator lobbies (Chapter 30). Section 709.5 requires openings in smoke barriers to be protected in accordance with Section 716, which includes requirements typical of a fire door assembly.

There is an exception for cross-corridor double egress pairs in some health care facilities, and the requirements for these doors are shown in section 709.5. There are essentially three sets of requirements for doors in smoke barriers because of the extensive exception for health care facilities and elevator lobbies, so I will summarize the requirements separately.

Type 3a: Doors in smoke barriers – Underground Buildings, I-3 Occupancies, and Areas of Refuge

Typical Location: These requirements apply to Underground Buildings and Use Group I-3 (detention/correctional centers), and well as areas of refuge that are required to be separated with smoke barriers. The requirements for cross-corridor double-egress pairs in health care facilities are summarized in the next section (3b) and the requirements for certain types of elevator lobbies are covered as Type 3c.

Fire Rating Required? Yes. According to Section 709.5, “openings in a smoke barrier shall be protected in accordance with Section 716,” which includes a fire protection rating as indicated in Table 716.5 (2015 edition) / 716.1(2) (2018 and 2021 editions).

Closer Required? Yes. Sections 716.5.9 (2015 edition) / 716.2.6 (2018 and 2021 editions) state that the doors must be self-closing or automatic-closing.

Latch Required? Yes. Sections 716.5.9 (2015 edition) / 716.2.6 (2018 and 2021 editions) require an active latch bolt that will secure the door when it is closed.

Gasketing Required? Yes. Sections 716.5.3.1 (2015 edition) / 716.2.2.1.1 (2018 and 2021 editions) state that fire door assemblies in corridors and smoke barriers shall meet the requirements for a smoke and draft control assembly tested in accordance with UL 1784, with the maximum air leakage stated above. Section 716.5.3.1 of the 2015 edition also requires the installation of smoke doors to be in accordance with NFPA 105 – Standard for the Installation of Smoke Door Assemblies and Other Opening Protectives, and states that louvers are prohibited. In the 2018 and 2021 editions, this information is found in Sections 716.2.2.1.1 and 716.2.10.

~~~

Type 3b: Doors in smoke barriers – Group I-1 Condition 2, Group I-2, and Ambulatory Care Facilities

Typical Location: Cross-corridor double-egress pairs in health care facilities that are classified as one of these use groups.

Fire Rating Required? No. New language was included in the 2015 edition of the IBC which clarifies that these doors are not required to be fire rated, and the 2018 and 2021 editions include this clarification as well. Section 709.5.1 does require doors in I-2 occupancies and ambulatory care facilities to have vision panels with fire-protection-rated glazing materials in fire-protection-rated frames, although a complete fire door assembly is not required. The 2018 edition includes a further clarification that protective plates on these doors are not required to be labeled, and this is also included in the 2021 edition.

Closer Required? Yes. In the 2015 edition, section 709.5.1 requires doors in I-2 occupancies and ambulatory care facilities to be automatic-closing by smoke detection. Note that this exception in the 2015 edition does not allow self-closing doors to be used in this application. The section does not reference Use Group I-1 Condition 2, so doors in those occupancies may be either self-closing or automatic-closing per Section 716.5.9. A change was made in the 2018 IBC and carried forward in the 2021 edition, which specifies that these doors must be automatic-closing in accordance with Section 716.2.6.6, IF they are equipped with hold-open devices.

Latch Required? No. In the 2006 and prior editions of the IBC, positive latches were not required for these doors because the exception included the specific language: “Positive-latching devices are not required.” This sentence was removed in the 2009 edition of the IBC, and replaced with, “Where permitted by the door manufacturer’s listing, positive-latching devices are not required.” This language is also included in the 2012 through 2021 editions, but now that the IBC has clarified that these doors are not fire-rated, there are no manufacturers’ listings to comply with that would mandate positive-latching hardware.

Gasketing Required? No. There is no reference in Section 709.5 to UL 1784, but Exception 1 requires astragals or rabbets at the meeting edges, and the doors must be close-fitting within operational tolerances. The maximum allowable undercut is ¾-inch, and the doors must not have louvers or grilles. Frame stops are required at the head and jambs.

Type 3c: Doors in Smoke Barriers – Elevator Lobbies for Fire Service Access Elevators and Occupant Evacuation Elevators

Typical Location: Lobby enclosures for fire service access elevators and occupant evacuation elevators (except at the level of exit discharge).

Fire Rating Required? Yes. Sections 3007.6.3 and 3008.6.3 require the elevator lobby doorways (except doors to the hoistway, elevator control room, or elevator control space) to have a fire rating of 45 minutes and to comply with Section 716. This includes a fire protection rating as indicated in Table 716.5 (2015 edition) / 716.1(2) (2018 and 2021 editions).

Closer Required? Yes. Sections 716.5.9 (2015 edition) / 716.2.6 (2018 and 2021 editions) state that the doors must be self-closing or automatic-closing. Section 3008.6.3 specifies that doors serving elevator lobbies for occupant evacuation elevators must have fire doors that are automatic-closing upon receipt of any fire alarm signal from the emergency voice/alarm communication system serving the building (not required by Section 3007.6.3 for elevator lobbies serving fire service access elevators).

Latch Required? Yes. Sections 716.5.9 (2015 edition) / 716.2.6 (2018 and 2021 editions) require an active latch bolt that will secure the door when it is closed.

Gasketing Required? Yes. Sections 3007.6.3 and 3008.6.3 require fire door assemblies which comply with the smoke and draft control requirements. Sections 716.5.3.1 (2015 edition) / 716.2.2.1.1 (2018 and 2021 editions) state that fire door assemblies in corridors and smoke barriers shall meet the requirements for a smoke and draft control assembly tested in accordance with UL 1784, with the maximum air leakage stated above. Section 716.5.3.1 of the 2015 edition also requires the installation of smoke doors to be in accordance with NFPA 105 – Standard for the Installation of Smoke Door Assemblies and Other Opening Protectives, and states that louvers are prohibited. In the 2018 and 2021 editions, this information is found in Sections 716.2.2.1.1 and 716.2.10. In addition, Sections 3007.6.3 and 3008.6.3 require these doors to be tested in accordance with UL 1784 without an artificial bottom seal. This means that doors in these locations will need door sweeps or door bottoms which are listed for this purpose, and the frames are not allowed to have terminated stops.

Note: Section 3008.6.3 requires each fire door serving an elevator lobby for occupant evacuation elevators to have a vision panel consisting of fire-protection-rated glazing. The vision panel must comply with the requirements of Section 716 and be located to furnish clear vision of the occupant evacuation elevator lobby.

~~~

There are several different types of doors that could be described as “smoke doors,” such as doors in smoke partitions and smoke barriers, corridor doors in health care facilities, smoke and draft control doors, and doors in exit enclosures. Some of these doors are required to be fire door assemblies, others do not require a fire door label.

Type 4: Fire door assemblies in corridors and smoke barriers

Typical Location: Corridors and smoke barriers with a fire-resistance rating, that require fire-rated doors.

Fire Rating Required? Yes. Section 716 references the fire protection ratings indicated in Table 716.5 (2015 edition) / 716.1(2) (2018 and 2021 editions). Fire door frames with transom lights, sidelights or both shall be permitted in accordance with Section 716.5.6 (2015 edition) / 716.2.5.4 (2018 and 2021 editions). Fire door assemblies and shutters shall be installed in accordance with the provisions of this section and NFPA 80.

Note: The 2021 edition prohibits fire-protection-rated glazing in fire door frames with transom lights or sidelights in fire barriers required by Section 1207 of the International Fire Code to enclose energy storage systems.

Closer Required? Yes. Sections 716.5.9 (2015 edition) / 716.2.6 (2018 and 2021 editions) state that fire doors must be self-closing or automatic-closing, with the exception of communicating doors between hotel rooms as well as certain elevator hoistway doors with regard to elevator recall operations.

Latch Required? Yes. Sections 716.5.9 (2015 edition) / 716.2.6 (2018 and 2021 editions) require an active latch bolt that will secure the door when it is closed.

Gasketing Required? Yes. Sections 716.5.3.1 (2015 edition) / 716.2.2.1.1 (2018 and 2021 editions) state that fire door assemblies in corridors and smoke barriers shall meet the requirements for a smoke and draft control assembly tested in accordance with UL 1784, with the maximum air leakage stated above. The IBC also requires the installation of smoke doors to be in accordance with NFPA 105 – Standard for the Installation of Smoke Door Assemblies and Other Opening Protectives, and states that louvers are prohibited.

~~~

Type 5: Doors in exit enclosures and exit passageways

Typical Location: Stair doors required to be fire-rated, and doors within the exit passageway connecting the stair to the exit discharge.

Fire Rating Required? Yes. Section 716 references the fire protection ratings indicated in Table 716.5 (2015 edition) / Table 716.1(2) (2018 and 2021 editions). Fire door frames with transom lights, sidelights or both shall be permitted in accordance with Sections 716.5.6 (2015 edition) / 716.2.5.4 (2018 and 2021 editions). Fire door assemblies and shutters shall be installed in accordance with the provisions of this section and NFPA 80. Sections 716.5.5 (2015 edition) / 716.2.2.3 (2018 and 2021 editions) include a requirement for temperature rise doors, but the exception exempts buildings that are equipped throughout with an automatic sprinkler system.

Note: The 2021 edition prohibits fire-protection-rated glazing in fire door frames with transom lights or sidelights in fire barriers required by Section 1207 of the International Fire Code to enclose energy storage systems.

Closer Required? Yes. Sections 716.5.9 (2015 edition) / 716.2.6 (2018 and 2021 editions) state that fire doors must be self-closing or automatic-closing.

Latch Required? Yes. Sections 716.5.9 (2015 edition) / 716.2.6 (2018 and 2021 editions) require an active latch bolt that will secure the door when it is closed.

Gasketing Required? Maybe? In the 2015 IBC, Section 716.5.5 does not include a reference to UL 1784, but gasketing and a door bottom/sweep may be necessary in order to maintain stair pressurization. In the 2018 and 2021 editions, Section 716.2.1.4 states that fire door assemblies serving as smoke and draft control assemblies must be tested in accordance with UL 1784. Some code officials are interpreting the IBC to mean that stairwell doors must meet the requirements for exit enclosure doors AND for doors in a corridor, which brings in the limited airflow per UL 1784, which would require gasketing at the head and jambs. However, the International Code Council published an interpretation in 2014 that states otherwise. Check this blog post for more information.

~~~

I hope this summary helps clear up some of the questions about smoke door requirements, and explains the intent of the grey areas. The summary included above is a result of my research on the 2015, 2018, and 2021 editions of the International Building Code; the actual code publications should be consulted when comprehensive data is required and to ensure compliance with the applicable codes. The Authority Having Jurisdiction (AHJ) is responsible for interpretation of the codes and always has the final say.

You need to login or register to bookmark/favorite this content.

I hate to have you edit this again, but aren’t some of the requirements listed under “3b” for I-2 specifically for opposite swinging cross corridor doors? Other doors should still meet 716.

Hi Rick –

I don’t mind editing it, but I mentioned that it applies to double-egress pairs here:

Typical Location: Cross-corridor double-egress pairs in health care facilities that are classified as one of these use groups.

I will look and see if there are other places I can clarify that.

– Lori

Yes, you did. But I don’t want someone to assume that “Typical Location” is equivalent to “All doors in smoke barriers”. Like all Code, it’s the nuance that catches us. Most smoke compartments only communicate through cross-corridor double egress doors, but there’s always that one door…..

Ok – I will clarify. Thanks for the suggestion!

– Lori

This subject has always been entertaining, and your knowledge is invaluable to hardware spec writers.

As anyone can see, there are numerous scenarios and variables involved and it can become confusing and frustrating when under the gun to complete a hardware spec. Back when I was active (working) and writing hardware specs, I broke this topic into 3 basic hardware sets.

1. If the architect’s door schedule just had “smoke door” in the remarks column, I gave the door smoke rated gasketing and made it self-closing. What good is the gasketing if the door doesn’t close against it?

2. If the remark was “20 min. smoke door”, but did not call for a fire rating in the door schedule, I made it self-closing, positive-latching and used combination fire & smoke rated gasketing.

3. If the door was specified to have a fire rating, I treated it like item 2 above.

This usually covered the bulk of scenarios and I would put a note in the preamble that if the door manufacturer (in particular, wood door) includes intumescent gasketing as part of their labeling procedure, then the combination fire & smoke rated gasketing in the hardware set can be changed to smoke rated gasketing.

Most times, when you are writing a spec, you’re lucky if you get drawings that are 80% complete and you’re really lucky if it has architectural details. There were several times where I was furnished with drawings that didn’t even have the door types drawn and, of course, they wanted the spec in less than a week.

It seems that things have become increasingly difficult and I don’t miss it at all. I only miss the wonderful people in our industry.

Thanks Jerry! Your strategy relies on the architect putting the right notation on the door schedule, so hopefully they were on top of it! 🙂

– Lori

For a wood door always order a 20 min fire label

It might add $20.00 to the cost.

For the HM or TIMELY steel frame always get a 90 min fire label It might add $20.00 to the cost.

Now when the fire marshall says I want this to be a smoke door AKA 20 min fire door. All you need now is smoke seal Pemko S88D & a surface closer and its ready.

verses uninstalling the opening repurchase with labels reinstall or have a Warnock Hersey relabel in the field @ $1500.00 to show up…

Thanks for the article update, these door type questions come up several times a week !

I Have A College That Has Recently Been Remodeled With Full Sprinkler Coverage And A New Fire Alarm System. In The Corridors There Are 8 Sets Of Double Smoke Doors That Were Required Before The Building Was Sprinkled. Is There Any Reason Or Code That Says I Can’t Remove These Doors??

Hi Ron –

I would definitely coordinate with the AHJ before removing the doors.

– Lori

I have been arguing with people about this countless times over the years and I still can’t find a solid answer.

Is smoke gasketing required on S rated doors on the hinge side jamb if the doors are installed with listed continuous hinges? The answer has to be no, right? There is no gap and you can’t make it work anyway. AHCA and countless others have argued to the contrary.

Cory, I’m afraid the answer would be “Yes” you would still need seals on the hinge jamb side of the opening, and here’s why. The Continuous hinge (let’s use the Ives 112XY for example) has been tested to UL10C, a fire test. It has not been tested to UL1784. So therefor it would not be code compliant to prevent the passage of smoke.

I get that, but it’s also a solid piece of aluminum with no gaps, and no means to install adhesive smoke seals on hinge side of jamb, leaving a surface applied bolt-on application as the only recourse and most facilities do not want that. I just don’t understand how the LACK of a smoke rating is even relevant when you’re talking about something that is a solid piece from top to bottom.

Cory,

I would agree with the logic behind your reasoning but if an AHJ wanted to see proof that the continuous met UL1784 there would be none and you would need to add some sort of seal that meets the UL1784 standards.

-Mark

Hi Lori,

I’m curious about gaps on smoke doors.

The NFPA doesn’t mention them. Is that because they are assumed to be the same as on fire doors, or because they are not in the inspection guidelines for smoke doors?

Loren Studebaker

Thank you for breaking down the smoke door requirements so clearly! It’s always helpful to have insights directly from an expert like Lori Greene. I appreciate the detailed examples and explanations—this will definitely help us stay compliant with the International Building Code. Looking forward to more posts like this!