I have recently run into aluminum doors on a few different projects which have unusually small jambs – the jamb depth of the aluminum extrusion is very close to the door thickness. So imagine a 2″ thick aluminum door and a jamb that is just a little wider than that.

I have recently run into aluminum doors on a few different projects which have unusually small jambs – the jamb depth of the aluminum extrusion is very close to the door thickness. So imagine a 2″ thick aluminum door and a jamb that is just a little wider than that.

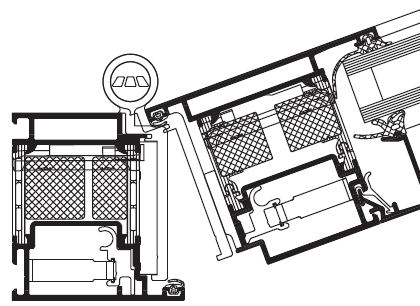

It’s extremely difficult to use “typical” hardware on these doors, since the push side face of the frame is essentially flush with the push side face of the door. This affects closers, exit device strikes, electromagnetic locks, and probably other products that I haven’t had issues with yet.

The hinges are usually supplied by the manufacturer, but on all of the projects where I’ve seen these doors, the architect wanted to use US-made hardware to match the rest of the building. I went into a building the other day where I had communicated several times that the specified hardware wouldn’t work with the flush frame, and I saw the application below. Ouch.

Jamb detail courtesy of Schuco.

You need to login or register to bookmark/favorite this content.

surprised to see that there was enough room for everything up there on the photo you have shown here. any closer to the locks and the ends of the closers arms will be rubbing or banging against the mag lock (eeeks, exposed wires, what an eyesore!)

about european doors/hardware (Germany especially) you will find LOTS of flush jambs and LOTS of closers that are either on the pull side of the door or using a sliding rail arm, alot like the graphic you have for “rescue hardware” the rabbited edges of a euro door is for better weather protectionand for protection against jimmying the lock (opening it with a butterknife or credit card from the pull side of door)

if I was to come across a door like this, there’s 2 options, install closer on pull side of the door, of if its REQUIRED to be on push side, put in one with a track/rail style arm

above installation of those LCN’s will still work, but just can look bad with those angle plates for the parallel arm brackets.

-Jess the door doctor