Once upon a time (almost 12 years ago), I wrote about the exciting topic of empty/unused silencer holes in fire door frames. The question has come up again and I have a little more information to share.

Once upon a time (almost 12 years ago), I wrote about the exciting topic of empty/unused silencer holes in fire door frames. The question has come up again and I have a little more information to share.

Quick Question: On a fire door assembly where adhesive smoke gasketing is installed, is it acceptable to have open silencer holes under the gasketing?

On the original post, one AHJ and long-time iDigHardware reader commented that the contemplation of silencer holes was on par with ruminating about naval lint, BUT – varying interpretations of the fire door assembly requirements can create huge (and costly!) problems in the field. Similar to Monday’s question about adding continuous hinges to existing fire doors, open silencer holes fall into a gray area, as this issue is not specifically addressed in NFPA 80 (it’s on my wish list for the next cycle!).

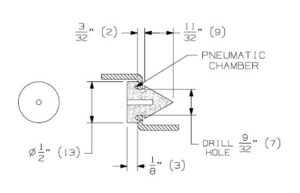

First, what is a silencer? For such a small and inexpensive piece of door hardware, silencers play an important role. They are small rubber “mutes” installed on door frames to reduce the noise associated with closing the door. They are typically installed in small holes drilled in the stop of the frame, and the door closes against them. Most silencers are about 1/8-inch thick, and help to maintain proper alignment of the door in the closed position – this also helps with secure latching of the locking hardware.

First, what is a silencer? For such a small and inexpensive piece of door hardware, silencers play an important role. They are small rubber “mutes” installed on door frames to reduce the noise associated with closing the door. They are typically installed in small holes drilled in the stop of the frame, and the door closes against them. Most silencers are about 1/8-inch thick, and help to maintain proper alignment of the door in the closed position – this also helps with secure latching of the locking hardware.

When adhesive gasketing is installed in the frame rabbet/stop, silencers are not needed and would conflict with the gasketing. As hollow metal frames almost always come prepared for the silencers, the small silencer holes are covered by the smokeseal, but technically they are open holes. Although NFPA 80 does not mention silencers holes, one of the fire door assembly inspection criteria listed in the standard is the verification that no open holes or breaks exist in surfaces of either the door or frame.

According to NFPA 80, the acceptable methods for filling fastener holes are found in Chapter 5:

When fastener holes are left in a door or frame due to changes or removal of hardware or plant-ons, the holes shall be repaired by the following methods:

(1) Install steel fasteners that completely fill the holes.

(2) Fill the screw or bolt holes with the same material as the door or frame.

(3) Fill holes with material listed for this use and installed in accordance with the manufacturer’s procedures.

On one hand, no open holes are allowed by the standard, but on the other hand, silencer holes are not “fastener holes.” From a common sense standpoint, the holes are covered by the gasketing, and the door also covers the holes when it is in the closed position. Smoke transmission through the holes should not be an issue because of the gasketing, and the silencers would melt during a fire test, leaving the small open holes. If the assembly passed the test with the missing/melted silencers, the assembly should perform properly during an actual fire.

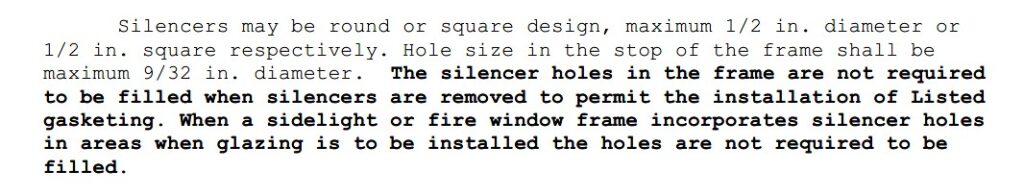

I did some digging with the help of our hollow metal engineer, and the issue of open silencer holes is specifically addressed in Steelcraft’s fire door frame file:

The size/quantity of silencer holes is detailed in UL 63 – Outline of Investigation for Fire Door Frames, with no mention of omitting or filling the holes when gasketing is installed instead of silencers. I have never heard of the silencer holes being filled, and neither had our listing lab representative.

Issues that are not specifically addressed in the adopted codes or referenced standards are left up to interpretation by the code official, and to be perfectly clear, I am not an AHJ. However, the open silencer holes seem to be allowed by Steelcraft’s listings (other manufacturers’ listings may not specifically address this issue). Ideally, this will be addressed in a future edition of NFPA 80, but in the meantime we need to rely on the manufacturers’ listings and the intent of the standards.

What do you think? I would love to hear your insight on this issue!

You need to login or register to bookmark/favorite this content.

Depending on the type of the smoke gasket, it does not cover the holes of the silencers. So that doesn’t cover the holes if installed per the manufactures instructions. This is an interesting question though.

I would think that a door silencer would melt/burn when subjected to the heat from a fire. I don’t think it would last for an hour. If smoke is the issue, then there would have to be some kind of negative air pressure within the walk to pull the smoke through the hole in the frame left by the melted or missing silencers.