After last week’s focus on fire doors for Fire Prevention Week, several people asked about altering fire doors in the field. This recent article that I wrote for Locksmith Ledger covers the requirements and limitations of NFPA 80.

~~~

When working on an existing fire door or labeled frame, many locksmiths, installers, and integrators are apprehensive about performing alterations that may void the rating of the assembly. This is a valid concern, but with an understanding of the limitations that apply to this work, fire door assemblies may be safely modified in the field.

When working on an existing fire door or labeled frame, many locksmiths, installers, and integrators are apprehensive about performing alterations that may void the rating of the assembly. This is a valid concern, but with an understanding of the limitations that apply to this work, fire door assemblies may be safely modified in the field.

There are two basic types of fire door assembly alterations addressed by NFPA 80:

- Job Site Preparations: These are changes made in the field that are specifically allowed by NFPA 80 – Standard for Fire Doors and Other Opening Protectives.

- Field Modifications: This work must be approved in advance by the listing laboratory (for example, Underwriters Laboratories or Intertek) and can then be done without requiring the door or frame to be relabeled.

If a proposed change to a fire door assembly is not allowed as a job site preparation or a field modification, it may be able to be performed under label service or the door or frame may be able to be relabeled in the field after the work is completed. This should be determined prior to the commencement of the work.

In the most recent edition of NFPA 80 (2022), alterations to existing fire door assemblies are covered in Chapter 5 – Inspection, Testing, and Maintenance. The section that addresses both job site preparations and field modifications is Section 5.1.5 – Modifications.

Job Site Preparations

NFPA 80-2022 addresses job site preparations of fire doors in Section 5.1.5.2 – Job Site Preparation. This section permits limited alterations to be made on the job site, including:

- Holes for surface-applied hardware – applied to the door or frame without removing material other than drilling round holes to accommodate cylinders, spindles, and similar operational elements, electrified hardware, as well as through-bolts

- Function holes for mortise locks

- Holes for labeled viewers

- Maximum 3/4-inch wood and composite door undercutting

- Installation of protection plates

Surface vertical rod or rim panic hardware (fire exit hardware) would be considered surface-applied hardware, as would retrofit electrified lever trim for fire exit hardware – as long as the required job site preparations only involve round holes. Most door closers, automatic operators, direct-hold electromagnetic locks, gasketing, and coordinators are also surface applied, and function holes for mortise locks and holes for labeled viewers are specifically allowed by this section of NFPA 80.

Previous editions of NFPA 80 limited the maximum diameter for round holes drilled in the field to 1 inch, except cylinders which could be drilled in the size necessary to accommodate the cylinder. A new paragraph was added to the standard in the 2016 edition and was carried forward in the 2019 and 2022 editions. This change allows larger round holes for surface-mounted hardware to be drilled in the field, in accordance with the listings of the door and hardware manufacturers.

Previous editions of NFPA 80 limited the maximum diameter for round holes drilled in the field to 1 inch, except cylinders which could be drilled in the size necessary to accommodate the cylinder. A new paragraph was added to the standard in the 2016 edition and was carried forward in the 2019 and 2022 editions. This change allows larger round holes for surface-mounted hardware to be drilled in the field, in accordance with the listings of the door and hardware manufacturers.

Before drilling larger holes, it is important to verify whether the manufacturers’ listings allow these holes to be drilled in the field. When the hardware manufacturer’s installation instructions for a listed product show a field preparation for a hole, those installation instructions and templates are part of the listing file. This establishes that the hardware manufacturer’s listing allows the field prep. But the door or frame manufacturer’s listings must also allow the prep and confirming this could take a little extra legwork.

Another change that was made in the 2016 edition of NFPA 80 is related to wire raceways, which accommodate wires that pass through the width of the door between electrified hardware and an electric power transfer or electric hinge. This preparation may be performed at the job site in accordance with the door manufacturer’s listings, and when permitted by the listing laboratory. If a door manufacturer’s listings do not include provisions for drilling raceways, the raceway is considered a field modification (see below).

Field Modifications

When an alteration to a fire door assembly is made in the field, and it is not permitted by NFPA 80 as a job-site preparation, it is considered a field modification. In the 2022 edition of NFPA 80, this work is addressed in Section 5.1.5.1 – Field Modifications.

If an alteration is not prescriptively allowed as job site preparation, permission may be requested in advance for a field modification. This is typically done by contacting the manufacturer of the component being modified; the manufacturer will then contact the appropriate listing laboratory with a written or graphic description of the modification. Some examples of preps that would not be considered job site preparations: a mortise lock pocket, cylindrical lock prep, concealed closer or concealed overhead stop, mortise for butt hinge, or shear lock. These preps might be allowed as a field modification.

For example, most electric strikes require a rectangular cutout in the face of the frame, and job site preparations are limited by NFPA 80 to round holes. Permission to make the rectangular modification in the field may be approved by the listing lab, after permission is requested through the frame manufacturer. Raceways would also require pre-approval if the door manufacturer’s listings did not address raceways drilled in the field.

If the manufacturer of the component being modified is no longer available, the lab may be contacted directly, and an engineering evaluation supporting the field modification may be provided. A field visit from the listing laboratory is not required if permission for the field modification is granted by the lab. If modifications are made without prior approval, the doors and/or frames may need to be re-labeled by the listing laboratory, which can be costly.

Filling Holes

Job site preparations and field modifications sometimes result in holes left in the surface of the door or frame due to the removal of existing hardware. In the 2013 edition and prior, NFPA 80 required holes to be repaired by one of two methods: installing steel fasteners that completely filled the holes or filling the screw or bolt holes with the same material as the door or frame. The 2016 edition of the standard clarified that the holes addressed by these methods were intended to be fastener holes.

Job site preparations and field modifications sometimes result in holes left in the surface of the door or frame due to the removal of existing hardware. In the 2013 edition and prior, NFPA 80 required holes to be repaired by one of two methods: installing steel fasteners that completely filled the holes or filling the screw or bolt holes with the same material as the door or frame. The 2016 edition of the standard clarified that the holes addressed by these methods were intended to be fastener holes.

A third method for filling fastener holes was added to the 2016 edition of NFPA 80: “Fill holes with material listed for this use and installed in accordance with the manufacturer’s procedures.” This acknowledges the use of other materials that can be used to fill holes, but only if the product is listed for filling holes in fire doors. If a product has been tested and listed for filling voids in walls or other surfaces, that does not necessarily mean that it can be used to fill holes in fire door assemblies.

At this time, there are very few products that have been listed for use in fire doors and there are strict limitations on where they are used. It’s important to verify the manufacturer’s listings regarding the size of the hole, the door or frame material, and the rating of the assembly. Filling holes that are not fastener holes is typically treated as a field modification, with permission required from the manufacturer/listing lab.

Conclusion

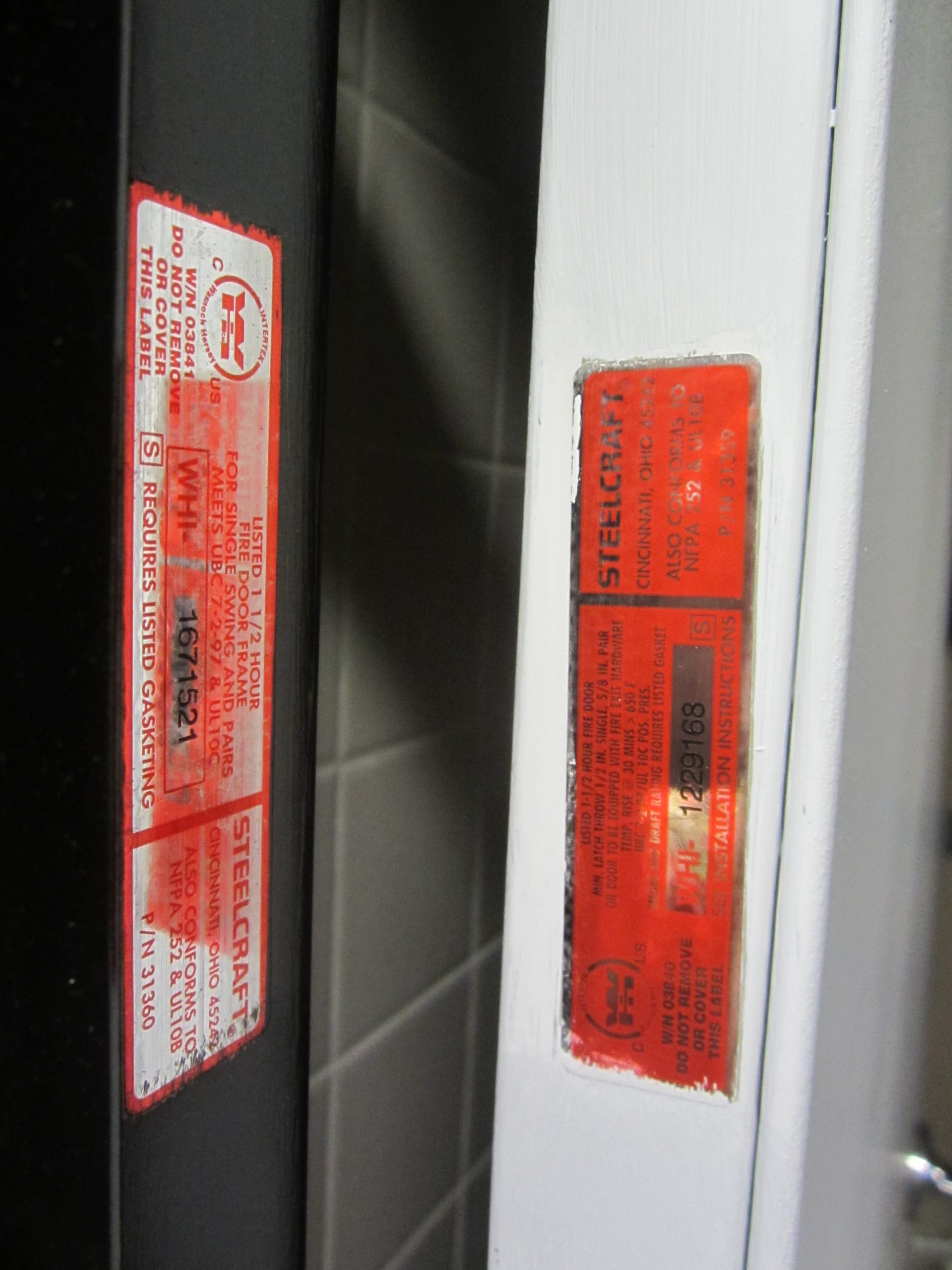

When preparing to perform a field modification or when questions arise, it’s best to avoid problems by conducting research and planning in advance. While NFPA 80 gives some direction with regard to protocols that must be followed when making alterations in the field, to get definitive answers you may have to contact the manufacturer of the component being modified, or even the listing laboratory on the label. The door or frame label will contain helpful information to identify the manufacturer and test lab, along with a number which can be used to obtain more detailed specifications. The manufacturer should be the starting point for most requests, and then the listing laboratory.

When modifying a fire door assembly in the field, keep in mind that each component attached to a swinging fire door must be labeled for this use. Typically, the product must be tested in accordance with UL 10C – Standard for Positive Pressure Fire Tests of Door Assemblies, or NFPA 252 – Standard Methods of Fire Tests of Door Assemblies, using the positive pressure test method. Components that are not listed to these test standards may not be installed as part of a fire door assembly.

Since the 2007 edition, NFPA 80 has required annual inspections of fire door assemblies, to ensure that they will perform as designed and tested if a fire occurs. Beginning with the 2013 edition of the standard, fire door assembly inspections are also required after installation, and after maintenance work. The alterations mentioned in this article would likely result in the need for an inspection of the fire door, frame, and hardware.

It’s important to note that the adopted code in a particular jurisdiction will reference a specific edition of NFPA 80, which may have different requirements than the most current version of the standard referenced in this article. In addition, there may be local requirements that could affect what is allowed in the facility’s location. The Authority Having Jurisdiction (AHJ) will have the final say.

You need to login or register to bookmark/favorite this content.

Leave A Comment