This post was published in Door Security + Safety

.

Although thresholds and gasketing are not very complicated when compared to other types of door hardware, I often receive questions related to the use of these products on fire door and smoke door assemblies. The codes and standards do not contain much prescriptive information with regard to sealing the area around the door, and the requirements vary depending on where the door is located within the building. Fire barriers, smoke barriers, smoke partitions, and doors constructed to resist the passage of smoke all have variations that make these simple products more difficult to specify and supply correctly.

Here are answers to some of the most frequently-asked questions about thresholds and gasketing:

Is gasketing required for all fire door assemblies and/or all smoke door assemblies?

Corridor doors in a residential occupancy are typically 20-minute fire doors that are also smoke and draft control doors.

Current model codes call for some doors to have a maximum air leakage rate of 3.0 cubic feet per minute per square foot [0.015424 m3/(s • m2)] of door opening at 0.10 inch (24.9 Pa) of water for both the ambient temperature test and the elevated temperature exposure test. The test standard used to determine air leakage is UL 1784 – Standard for Air Leakage Tests of Door Assemblies and Other Opening Protectives. Although the codes and standards do not specifically state that gasketing is required, it is difficult or impossible to limit air leakage to the required level without gasketing at the head and jambs, and the meeting stiles of pairs of doors.

Not all fire doors and smoke doors are required to have air leakage limited to this level – the key is to look for the reference to UL 1784 in the requirements for a specific door location. For example, the IBC requires this limited airflow for fire doors that are also smoke and draft control doors in corridors and smoke barriers. In addition, the IBC requires limited air infiltration and references UL 1784 for the following locations: elevator lobby doors, and doors in smoke barriers in underground buildings and I-3 occupancies (i.e. correctional centers, detention centers, jails, pre-release centers, prisons, and reformatories).

Fire door assemblies are required to comply with NFPA 80 – Standard for Fire Doors and Other Opening Protectives, and some smoke doors must comply with NFPA 105 – Standard for Smoke Door Assemblies and Other Opening Protectives. NFPA 80 does not reference UL 1784, but NFPA 105 includes the same limitation as the model codes. With that said, there are limited locations where doors are required to comply with NFPA 105. For example, NFPA 101 currently requires smoke-leakage rated assemblies for new fire doors serving an area of refuge, and requires compliance with NFPA 105 for new door assemblies in three locations: vestibules that are part of a smokeproof enclosure, horizontal exits, and elevator lobby doors in occupant evacuation elevator shaft systems.

Are gasketing products for fire doors and smoke doors required to be labeled?

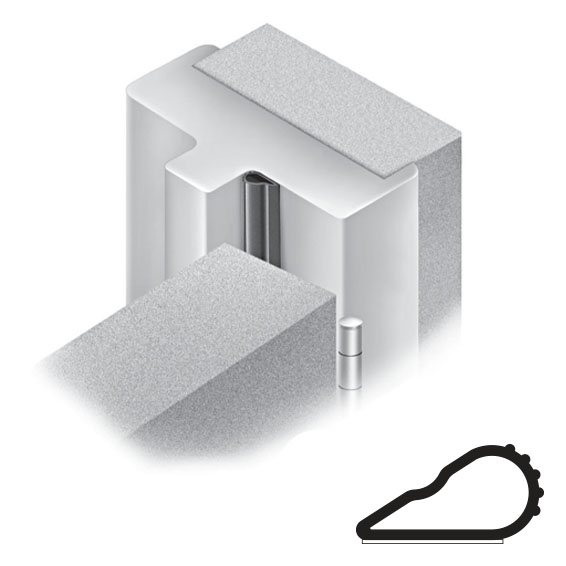

A fire door assembly is an assembly of components that have been tested to UL 10C or NFPA 252, using the positive pressure fire test method. These components may be from different manufacturers or listing laboratories, but all components must be listed – including gasketing and thresholds. This testing ensures that the products will not negatively impact the performance of the fire door assembly during a fire. According to the NFPA 80 Handbook, “Gasketing is a product that might not have an actual label attached to it, due to the design and shape of the product. In this case, the packaging of the gasketing material will bear the label.”

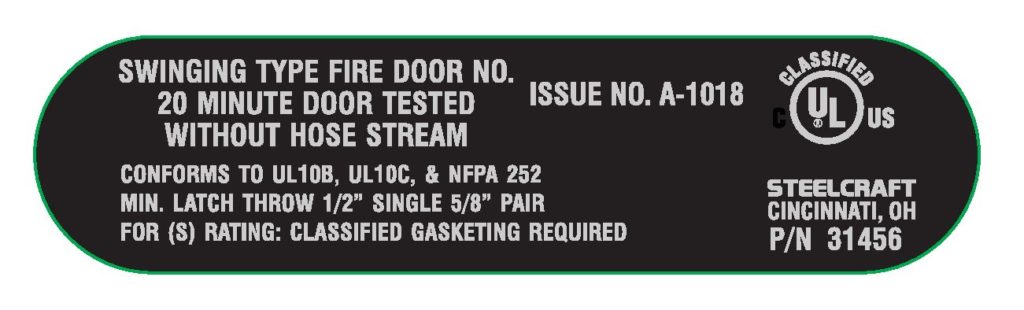

Smoke doors will typically have an “S Label” which states that the assembly meets the requirements for limited air leakage when classified gasketing is installed. Gasketing manufacturers’ catalogs indicate which products are listed to limit the smoke transmission to the level stated in the codes and standards, when tested in accordance with UL 1784.

The ‘S label’ indicates that classified gasketing is required in order to limit air leakage to the level stated in the code or standard.

Can thresholds, door bottoms, and gasketing be used to bring doors with oversized clearances into compliance?

Excessive clearance is one of the most common deficiencies found during annual fire door assembly inspections. It’s a common misconception that any listed gasketing products can be used to bring a door with oversized clearances into compliance. There are many types of gasketing, thresholds, door bottoms, and sweeps that are listed for use on a fire door. However, almost all of these products are designed and tested for use on doors which have clearances within the acceptable limits shown in NFPA 80. Installing this gasketing on a non-compliant fire door assembly will not bring the opening back into compliance.

Several products have been introduced in the last few years that are tested and listed for use on fire doors with clearance that exceeds what is allowed by NFPA 80. When using these products, it’s very important to consider the limitations of the product – for example, the maximum clearance that the product has been tested to accommodate, the door/frame material, and the rating. Another important consideration is the latch throw – if the latch-side clearance is too large (even if sealed with gasketing), the latchbolt may not project far enough into the strike to satisfy the manufacturer’s listing requirements.

The 2016 edition of NFPA 80 has been updated to include references to these types of products, allowing their use for doors with clearance in excess of what is allowed by the standard when the products are installed in accordance with their listings. Prior to the 2016 edition, NFPA 80 did not mention any methods of resolving oversized-clearance problems, but all editions of the standard include alternative methods and equivalency. This would allow AHJ approval of listed products even if they are not specifically addressed in NFPA 80.

When is a threshold or door bottom required for a fire door or a smoke door?

Thresholds are rarely mandated by the codes and standards for fire doors or smoke doors, but when they are used in these applications, thresholds must be listed to UL 10C or NFPA 252.

The UL 1784 test standard states, “In order to obtain information on the extent of air leakage at the ungasketed bottom gap of a test sample, an artificial seal may be applied to the bottom 6 inches (152.4 mm) of the test sample. The artificial seal may be any material, such as an impermeable sheet or tape.” By testing air infiltration with the artificial bottom seal in place, any air that would have passed through the bottom 6 inches of the door opening is not considered, so leakage at the balance of the perimeter can be accurately measured.

When a fire door assembly is subjected to a positive pressure fire test, very little smoke passes beneath the door during the test. Because of the location of the neutral pressure plane, the air is drawn toward the fire below the door and pushed out away from the fire above the neutral pressure plane – basically above the typical lock height. The positive pressure test is designed to accurately replicate the conditions encountered during an actual fire, so if smoke does not pass below the door during the fire test, openings in this area of the fire door assembly should not be of major concern in a fire situation.

For most doors, a seal at the bottom is not mandated by the codes or standards, unless the door is required to meet the stated limits for air leakage without the artificial bottom seal installed during the test. If the door must be tested without the artificial bottom seal, it would typically require a sweep or automatic door bottom – both during the test and on the final assembly installed in the field. For example, the IBC requires the UL 1784 test without the artificial bottom seal for some doors in elevator lobbies and hoistways.* The reason for this is that in a fire affecting an elevator hoistway, the neutral pressure plane would not necessarily fall at 40 inches above the bottom of the door, so we can’t assume that a door bottom seal is not needed.

Thresholds are not typically required by the codes and standards for fire door assemblies, although there may be a need for them when combustible floor coverings are used, depending on the critical radiant flux and the rating of the fire door assembly. In locations where a door bottom or sweep is required to meet the limitations of UL 1784 without an artificial bottom seal, installing a threshold provides a surface for these products to seal against. When a threshold is installed as a component of a fire door assembly, it must be listed for that purpose.

In NFPA 80, is a sill the same as a threshold?

In the past, the use of the term “sill” in NFPA 80 caused some confusion, so this has been clarified over several recent editions of the standard. In the 2010 edition (and prior), there was no definition of the terms threshold or sill for swinging doors, and there were some paragraphs within the standard where the term “sill” might be interpreted to mean a threshold. A definition for sill was added in the 2013 edition: “The bottom part of an opening over which a fire door closes,” but this didn’t go quite far enough to clarify the intent of the standard.

The 2016 edition includes a revised definition for sill: “A structural component of the building that forms the bottom part of an opening over which a door closes,” and a new definition for threshold: “A builders hardware component that is installed beneath a closed door.” The NFPA 80-2016 Handbook also clarifies that “A component located in the bottom part of an opening is often incorrectly referred to as a sill. The component forming the bottom part of an opening where the fire door closes is only a true sill if it is a structural component, not simply aesthetic or serving another function such as connecting multiple types of floor coverings.”

Why is this clarification important? Here’s an example. When NFPA 80 requires sills to have a minimum width of 4 inches, some have interpreted that to mean that fire door assemblies are required to have a 4-inch wide threshold. Fire door assemblies are not typically required to have thresholds, so defining the terminology helps to establish that the (minimum) 4-inch sill is actually part of the structure of the building – not a hardware component.

How is gasketing continuity tested during a fire door / smoke door assembly inspection?

To determine whether gasketing is required, look for a reference to UL 1784 among the requirements for a door assembly in a particular location.

If gasketing on a particular fire door or smoke door is required by a code or standard, the annual inspection requirements of NFPA 80 and NFPA 105 include verification that the gasketing is present and continuous. I have heard that some AHJs use a flashlight to check for continuity, however, this method is not mandated by the model codes or standards, and there is no way to know how much light is too much, or how light transmission equates to air transmission.

In fact, this practice is addressed in a 2007 bulletin from the Centers for Medicare & Medicaid Services (CMS): “It has come to our attention that in limited instances a “light test” has been used to determine if the door gap is adequate or too large. (If the surveyor sees light through the door gap, he/she determines that the gap is too large and the provider is cited for a deficiency.) There is no criterion for a light test anywhere in the Life Safety Code or in other NFPA codes and standards.”

The presence and integrity of the gasketing can be verified by observing the condition of the material – it is not necessary to use a flashlight to test for continuity. If gasketing is required by code, it should not be notched or cut around hardware that may have been installed prior to the gasketing. If gasketing is not required by code, it is not required to be continuous, but if present on a fire door assembly, it must be listed to UL 10C or NFPA 252.

Conclusion

In summary, the use of gasketing on fire door assemblies and smoke door assemblies is dependent on the code section the doors must comply with. Look for a reference to UL 1784 to determine whether smokeseals are needed. Door bottoms (and often the accompanying thresholds) are required by code in very few locations – where doors must limit airflow without the artificial bottom seal installed during the air-leakage test. All products used on fire door assemblies must be listed to UL 10C or NFPA 252, and products installed on fire doors with excessive clearance must be specifically listed for that purpose. The adopted codes and standards should be consulted when comprehensive data is required and to ensure compliance with the applicable requirements. Consult the AHJ if additional information is needed.

~~~

Here are the locations where the 2024 IBC requires the door assembly to be tested to UL 1784 without the artificial bottom seal in place during the test:

- 405.4.3: Elevator lobby doors in underground buildings where the elevator serves more than one compartment

- 3006.3, Item 3: Elevator hoistway doors where hoistway protection is required by Section 3006.2.

- 3007.6.3: Doors to enclosed fire service access elevator lobbies, with the exception of doors to the hoistway, elevator control room, or elevator control space.

- 3008.6.3: Doors to occupant evacuation elevator lobbies, with the exception of doors to the hoistway, elevator machine rooms, machinery spaces, control rooms, and control spaces within the lobby enclosure smoke barrier.

Doors installed in these locations would typically require door sweeps or automatic door bottoms to reduce the airflow to the acceptable level. For smoke doors in other locations, the airflow at the bottom of the door is not taken into account during the test or in the field.

You need to login or register to bookmark/favorite this content.

is there a right and wrong way to install thresholds/sweeps?, There was a site that i noticed they installed them centered on the frame with the sweep on the push side of the door.

I don’t know if I’ve ever seen comprehensive information on this, but the sweep should go on the pull side and seal against the threshold.

– Lori

I personally use Assa Abloy and their technical support has always stated that the sweep should extend the full width of the door. My interpretation of this is it is implicit that the sweep should be installed on the pull side of the door, as this is the only side where the full width of the door can be achieved. I have contacted other manufacturers of door sweeps and they have all agreed with the above, stating that this is typically how the sweep is tested when it receives its UL rating.

Fantastic info Lori. It is interesting to note that even the code can’t seem to clarify door sills or threshold .

When it says continuous, if a portion gets damaged, do you need to remove the entire gasket? Or can you butt join a new section. Example would be a door where someone pulled about 12″ down on the overhead section, can you join two pieces? I’m thinking no, but would like to know for sure.

Hi Michael –

I’m not sure if that would void the UL 1784 listing – I would recommend checking with the manufacturer of your gasketing, and I will try to find out also.

– Lori

watch out for IBC 2015 Section 701.2

“Multiple use fire assemblies. Fire assemblies that serve multiple purposes in a building shall comply with all of the requirements that are applicable for each of the individual fire assemblies.”

It could add requirements for smoke and draft control doors to stair doors that are not required in a full sprinklered building where the corridor is permitted to be non-fire-rated.

See IBC interpretation www3.iccsafe.org/cs/committeeArea/pdf_file/BU_12_15_14.pdf

Hi Lori, if I have more than 3/4 clearance under a fire door and thresold is authorized under the door, may I use a fire rated thresold to help reduce this clearance ?

In my opinion, yes. The clearance is typically measured from the bottom of the door to the top of the threshold (if there is one), so as long as the listed threshold isn’t more than 1/2-inch high and the remaining clearance isn’t more than 3/4-inch, it should be compliant. An AHJ might disagree with me, but I believe this is the intent of NFPA 80.

– Lori

For getting an undercut door into compliance, are there any other products on the market, if a threshold is unacceptable to the facility? I know about Crown’s door extension, but it is a very expensive product. I appreciate your work in this field!

Hi Jeff –

I only know of a few products and they are on this blog post: https://idighardware.com/2017/06/qq-wwyd-excessive-clearance-on-fire-doors/.

– Lori

Is the width of the threshold a factor with a fire rated opening? For instance, can you use a 5″ Threshold in a 10 1/2″ frame that is 90-Minute rated? Do you have to cover the whole 10 1/2″?

Hi Nicole –

No – you don’t have to cover the whole 10 1/2 inches. There has been some confusion in NFPA 80 about the use of the words “sill” vs. “threshold” but they are 2 different things. There is a requirement in 80 about the width of the sill, but it doesn’t mean the threshold has to be that wide.

– Lori

Hello Lori,

Long time follower…

I often wonder why the bottom of the door is disregarded in fire testing and thresholds/door bottoms are not required.

Fire needs air to survive and thrive so would it not make sense to seal the bottom of fire doors as much as possible to prevent as much air flow as possible from being sucked into the room feeding the fire?

I understand the concept of not wanting smoke being pushed out but what about the air coming in from the other side under the door?

It seems like only half the battle is being addressed?

Do you have any knowledge of this or any code information as to why thresholds/door bottoms would not help with this?

Thanks, Keith

Hi Keith –

My understanding is that because of the pressures created during a fire, it’s not critical to seal the area at the bottom of the door. That part of the assembly is taped over during the UL 1784 test for air infiltration, so only the leakage at the head, jambs, and meeting stiles is measured.

– Lori

GREAT ARTICLE! I need a 20 minute fire jab and door, nothing about smoke. Its a group home. I think all doors that I looked at, came with a threshold. If that is the only option I can find, am I able to remove the threshold?

Hi Ed –

That’s going to depend on the door manufacturer’s listings. I would recommend checking with them.

– Lori

Lori, i appreciate this article. With regard to your comment:

“Thresholds are not typically required by the codes and standards for fire door assemblies, although there may be a need for them when combustible floor coverings are used, depending on the critical radiant flux and the rating of the fire door assembly. ”

What codes would govern when this needs to be done. Our campus is installing rubber gym matting that they would like to run under our 3 hour rated door. In principle I am trying to convince the contractor to break this fire assembly up, but I would like to have a leg to stand on with the codes. I am in New York State.

Thanks

Hi James –

In NFPA 80 it says:

4.8.5 Floor Coverings.

4.8.5.1 Combustible floor coverings shall be permitted to extend through openings required to be protected by 1 1∕2 hour, 1-hour, or 3∕4-hour rated fire protection fire door assemblies without a sill where they have a minimum critical radiant flux of 0.22 W/cm2 in accordance with NFPA 253 or with ASTM E648, Standard Test Method for Critical Radiant Flux of Floor-Covering Systems Using a Radiant Heat Energy Source.

4.8.5.2 Combustible floor coverings shall not extend through openings protected by 3-hour rated fire protection door assemblies.

I hope this helps! I don’t have a lot of experience with floor coverings!

– Lori

This is great! Thanks for all you do.

Just installed an internal fire door with no threshold, however the floor is not square a runs out some 30mm, subsequently when opening the door it sticks after only a third of the opening arc. Any advice?

Hi David –

That’s a common problem, but not an easy one to solve. If the door manufacturer will allow the door to be trimmed in the field (without voiding the label) so that it doesn’t stick, you will need to address the excess clearance when the door is in the closed position. This could be done by adding a threshold or possibly a door bottom or sweep that is listed for fire doors with more clearance than what is allowed by NFPA 80.

– Lori

Hi Lori,

You mentioned meeting the manufacturer’s listing requirements for a latchbolt projecting far enough into the strike, but i have not seen that. Can you provide an example? I’ve only seen the “latch throw” in any listings. I know we’ve discussed the whole latchbolt throw/projecting into the strike before, in regards to flushbolts. I just want to be certain if there’s an actual dimension given that I’m aware of it.

Thanks so much for all you do, and being the go to resource for so many of us.

Hi Robby –

I have looked for official documentation of that too, without much luck. I will check the Ives listings and see if I can find it.

– Lori

Hey all,

I know this is an old thread but as I was looking for more information about gasketing and the use of a flashlight, I looked at the appendix to NFPA 105 for item 6.7.1.1. It specifically states that “a bright concentrated beam of light can be used to verify that the gasketing material blocks the light from passing through the ungasketed side of the door . . .”. So even though the appendix is not technically the code, it does tell us to check with a flashlight. It’s interesting because the 2007 bulletin from the Centers for Medicare & Medicaid Services (CMS) says not to. I wonder if they updated the appendix specifically because of that CMS bulletin.

That’s really interesting! Thanks for taking the time to share this comment!

– Lori