I think I’ve mentioned before…I’m not a big fan of surprises, and one of my life goals is to help protect y’all from unexpected unpleasant hardware issues. Doors that are 6′-8″ in height are less common than they were 30 years ago, so sometimes we’re not prepared for potential conflicts with the required clear opening height.

I think I’ve mentioned before…I’m not a big fan of surprises, and one of my life goals is to help protect y’all from unexpected unpleasant hardware issues. Doors that are 6′-8″ in height are less common than they were 30 years ago, so sometimes we’re not prepared for potential conflicts with the required clear opening height.

The International Building Code (IBC) requires the minimum clear opening height of doors to be at least 80 inches. The IBC allows some projections into this clear opening height, stating: “Exception: Door closers and door stops shall be permitted to be 78 inches (1980 mm) minimum above the floor.”

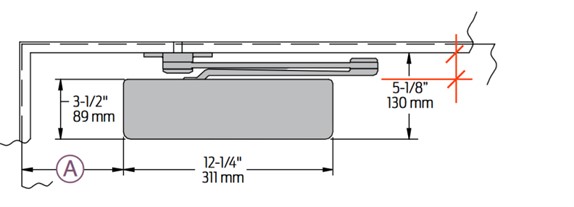

When a parallel arm closer is installed on a 6′-8″ door, the closer arm may or may not be a problem depending on the height of the stop on the frame (usually 5/8-inch) and the distance from the underside of the stop to bottom of the elbow on the closer arm. For example, an LCN 4111 EDA measures approximately 1 1/2-inch to the bottom of the elbow. When attached to a 5/8-inch stop there may not be 78 inches of clear height to the closer arm, depending on the conditions at the bottom of the frame as well as the flooring.

What exacerbates the problem is when there is a pair of 6′-8″ doors with a bar-type coordinator, and parallel arm closers. This installation moves the closer down farther into the opening because of the thickness of the coordinator and the thickness of the mounting bracket; this creates an even bigger problem than the closer arm alone. A gravity coordinator could help, but 7′-0″ doors would be even better.

Have you experienced this problem? What was your solution?

You need to login or register to bookmark/favorite this content.

The other things to look out for is mag locks and ADA clearance which on a 80 inch opening is below the head room clearance

I had a project recently with several 6’10” doors. Closers were not a issue but Mag Locks were. We brought it up early enough that all 6’10” openings were changed to 7’0″. I’m still not sure why 6’10” was used in the first place. It’s not like there is any cost savings over 7’0″.

Reminds me of the time I told an architect using 6-8 doors on a nursing home who wanted mag locks. I told them no and why.

They choose not to listen hired the local security company to installed mags. Best part of the story the building inspector hit his head on one of the mags on inspection.

Another issue with 6-8 doors occurs when the door is equipped with an overhead surface-applied stop. This requires a drop bracket for the PA arms, lowering them even further. It is much the same as the coordinator issue. I’ve run into this several times. Using a 7-0 door is the best way to avoid these issues.

Wouldn’t the 5/8″ dimension of the frame stop leave a clear opening of only 79-3/8″ which is already unacceptable before flooring, maglocks, or any other issues?