This Quick Question doesn’t really have a quick answer, but I’ll take a stab at it and then we can discuss it. Here’s the question:

This Quick Question doesn’t really have a quick answer, but I’ll take a stab at it and then we can discuss it. Here’s the question:

Can less-bottom-rod (LBR) fire exit hardware with an auxiliary fire pin be installed on an existing fire door?

First, some other questions…

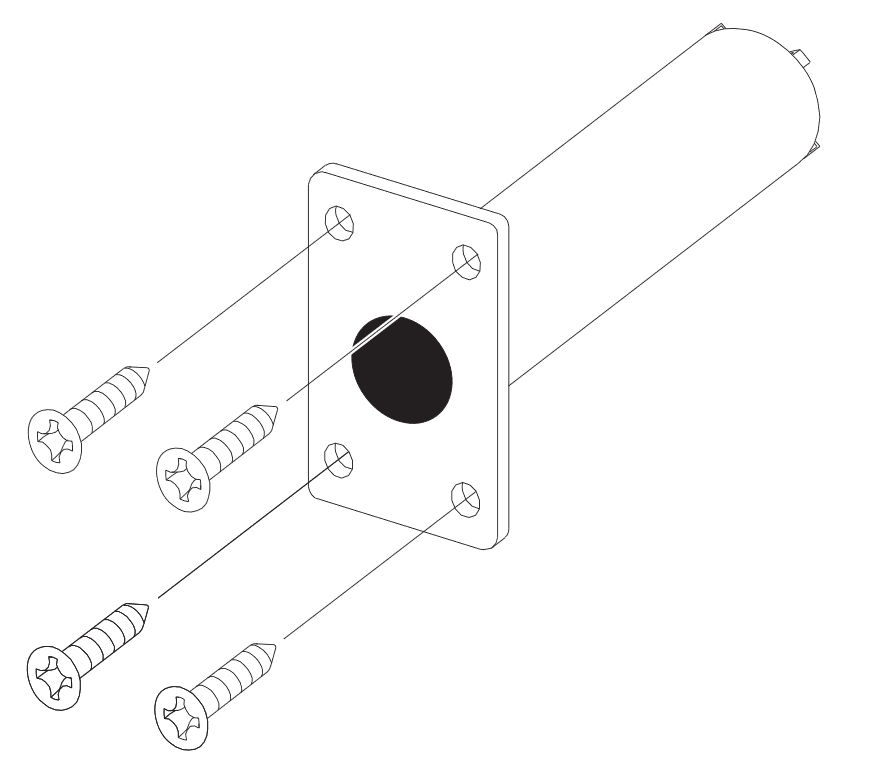

What is an auxiliary fire pin? When vertical rod fire exit hardware is installed without the bottom rods and latches, an auxiliary fire pin is typically required. It is installed in the edge of one leaf of a pair, and a hole is prepped in the other leaf. When the temperature reaches approximately 450 degrees F, the pin projects into the hole in the other leaf, to keep the doors aligned and help prevent the fire from spreading. (Note: Some door manufacturers may require fire pins projecting into the floor.) This Decoded article is all about less-bottom-rod fire exit hardware.

Doesn’t the projected pin impede egress? When the temperature is high enough for the pin to project, the doors are no longer being used for egress. Last month I posted a photo and some information about what happens to operable hardware during a fire – you can read it here.

Why would I want LBR devices and an auxiliary fire pin? Using fire exit hardware without bottom rods and latches helps to avoid maintenance issues, floor strikes, and problems with non-latching hardware. The increase in enforcement of fire door inspections has drawn attention to a lot of existing non-compliant fire doors. Replacing bottoms rods and latches with the auxiliary fire pin is a potential resolution for these problems.

So, back to the original question – there are several things to consider:

Do the listings for the existing doors allow LBR devices? It’s important to check with the door manufacturer before modifying the doors. Fire doors that pre-date the introduction of LBR fire exit hardware may not have been tested with these products. Listings that do allow LBR devices may require the strikes for the top latches to be changed to a different type.

Can the prep for the pin be made in the field? If the manufacturer’s installation instructions include field preparation for the pin, and the required holes are 1-inch diameter or less, there should not be a problem. This has been clarified in the 2019 edition of NFPA 80:

4.1.3.2.4 When performed at the job site, drilling raceways for wires or preparation for fire pins shall be in accordance with the door manufacturer’s listing and when permitted by the laboratory with which the door is listed.

What about existing holes and voids left by the removal of the bottom rods and latches? This is another question for the door manufacturer. If the rods and latches are surface-mounted, NFPA 80 includes provisions for addressing the fastener holes. If the rods and latches are concealed in the door, filling those voids would be considered a field modification that requires approval from the listing laboratory.

~~~

What is your experience with LBR devices? If you have insight to add, please leave a comment in the reply box!

Check out this very old post for a fire pin brain teaser.

You need to login or register to bookmark/favorite this content.

I would say that’s a no, as the door manufacturers have tested that application with specific stile components / reinforcement.

Hi Angie –

If the existing doors and fire exit hardware have been tested with LBR devices, and the manufacturer’s listings allow the prep for the pin to be done in the field and the existing holes to be filled, it is usually acceptable to remove the bottom rods/latches and install the pin. If the existing opening is old (installed before LBR devices were tested/listed), the answer depends on whether the design of the doors and hardware was changed in order to pass the fire test without the bottom rods and latches. I hope that makes sense.

– Lori

Something else to watch for – some wood door manufacturers require a second pin on the bottom edge that projects into the floor.

Thanks Jack! I’ll add that to the post.

– Lori

Which Allegion brands of hardware have kits to fill the bottom holes of exit devices that are going to being converted to”less bottom rod” or installed straight out of the box? Any other brands as well! Are less bottom rods tested with the holes filled? Thanks.

Hi Ron –

I have not seen such a kit. That’s why I mentioned in the blog post (last paragraph) that filling the holes and voids must be addressed by the door manufacturer’s listings or approved as a field modification.

– Lori

Is it possible for you and Jeff T. to pull information on Allegion products?

Hi Ron –

What info would you like?

– Lori