This post was published in Doors & Hardware

A preload fixture in the test lab, which applies force to the door before the latch is released. Photo: Allegion

The Builders Hardware Manufacturers Association (BHMA) is responsible for creating and maintaining standards used in the hardware industry, and is accredited by the American National Standards Institute (ANSI). These standards may be referenced in model codes such as the International Building Code (IBC) and NFPA 101 – The Life Safety Code, or in standards like NFPA 80 – Standard for Fire Doors and Other Opening Protectives and ICC A117.1 – Accessible and Usable Buildings and Facilities.

In addition to the use of these documents as referenced standards for code compliance, they are often listed in specifications to establish the level of quality desired for a project. For example, ANSI/BHMA A156.3 – American National Standard for Exit Devices, includes requirements for exit devices and trim, automatic and self-latching flush bolts, removable mullions, coordinators, and carry-open bars. The standard includes three product grades, with Grade 1 representing the highest level of quality.

To verify the durability of exit devices the standard requires several tests for panic hardware and fire exit hardware, including a cycle test with different levels of cycle testing required for each product grade. Grade 1 panic/fire exit hardware must be tested for at least 500,000 cycles, Grade 2 – 250,000 cycles, and Grade 3 – 100,000 cycles. This helps to establish minimum requirements for quality, although some manufacturers test their products well beyond the required minimums.

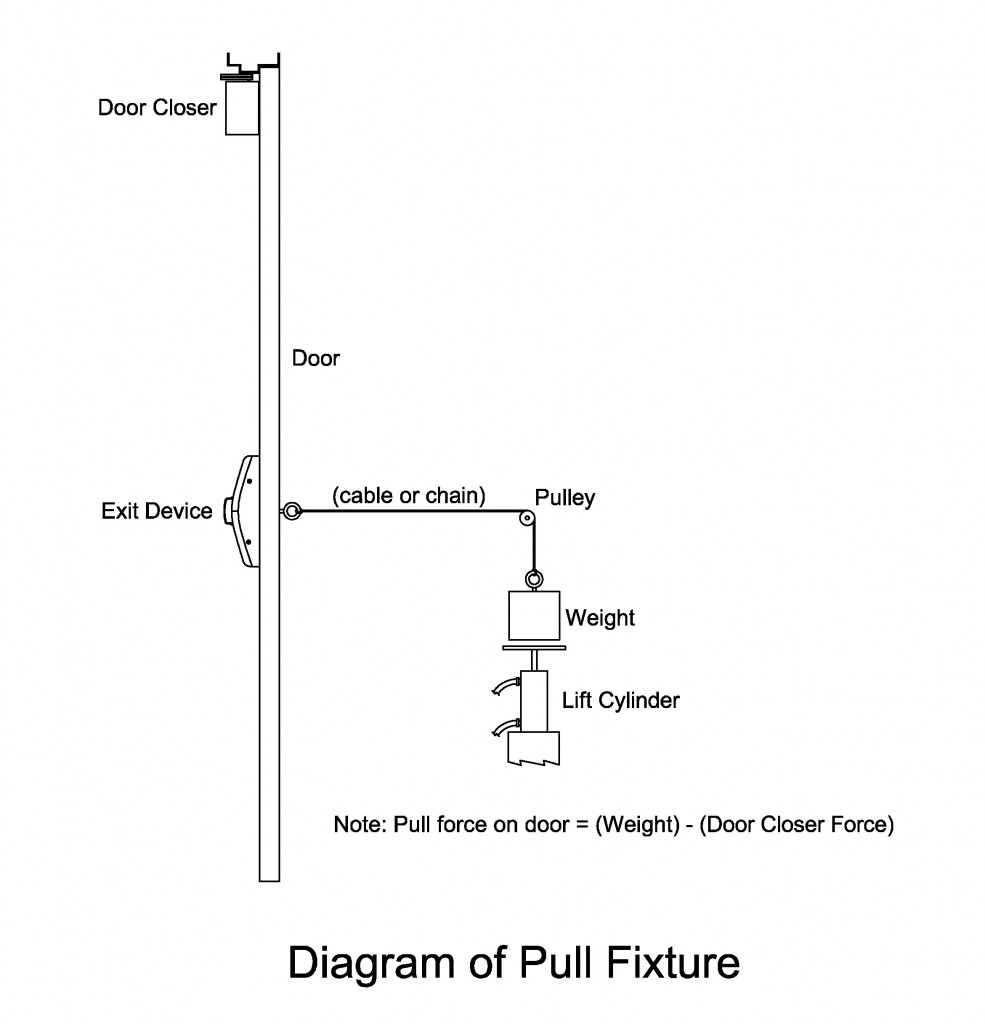

BHMA is required by ANSI to update and review each of the product standards every 5 years, and an important change was made to ANSI/BHMA A156.3 when it was last revised in 2014. The standard now requires cycle tests for Grade 1 exit devices to include preloading with a weight prior to the door being cycled. While the door is latched, a force of 20 to 22 lbf is applied in the direction of the door swing, 3 inches from the latch edge and 40 inches from the floor. After the preload force is applied, the hardware is then actuated, the door opens, closes, and latches, completing the cycle.

The purpose of the preloading requirement is to more closely duplicate real-world installations, where doors may be subject to additional loads because of gasketing, air pressure, misalignment of the door and frame, installation problems, or other factors. Devices tested in ideal conditions in the lab may not perform as well under normal conditions in the field, which are often less than perfect. Using a more realistic test helps to ensure that Grade 1 products will live up to expectations and perform reliably over time.

This diagram from ANSI/BHMA A156.3 illustrates a method for applying preload to a door for Grade 1 cycle testing. Image Courtesy of Builders Hardware Manufacturers Association

The new requirement for preloading makes the cycle test for Grade 1 products more difficult to pass than the previous cycle-testing requirements. Products which were certified as Grade 1 using the 2008 (or earlier) edition of ANSI/BHMA A156.3 may not meet the cycle test requirements under the revised standard. The change further defines the difference between Grade 1 products and products certified as Grade 2 or Grade 3.

In addition to cycle testing, ANSI/BHMA A156.3 describes the various functions and types of exit devices, and includes a numbering format; for example, a Type 1 device with a trim function of 15 indicates a rim device with a passage function (non-locking) knob or lever. The standard also includes performance criteria to evaluate the following:

- Operation – Forces required to open and close the doors are defined and measured, with the intent that the device will function in a similar manner when installed in the field. Both the actuating portion of the device on the push side of the door and the trim on the pull side are evaluated.

- Durability – Products used in a building are intended to provide many years of operation, so the standard includes tests to demonstrate the strength of the devices by pushing the crossbar or touchpad, and turning and pulling the trim.

- Safety & Security – Tests evaluate the ability of the products to withstand forced entry from the pull side, and a 400-pound load applied in the direction of egress.

- Appearance – The standard requires hardware finishes to resist corrosion, chemicals, abrasion, and sunlight to ensure that the finish will remain intact.

Tests described in the standard are performed by independent test labs, and manufacturers must retest products a minimum of every four years to maintain their ANSI/BHMA certification. Certified products are evaluated against the most current version of the standard.

When evaluating panic hardware and fire exit hardware it’s important to note which edition of ANSI/BHMA A156.3 is referenced by the code publication or the specification. BHMA lists certified products in an online directory, for easy confirmation of a product’s certification. Visit BHMA’s website at buildershardware.com, and click the link to search for BHMA certified products. Copies of the ANSI/BHMA standards can also be purchased from this website, and other technical information, including the online directory, is available at no charge.

You need to login or register to bookmark/favorite this content.

[…] Further, the National Fire Protection Association (NFPA) requires these assemblies to comply with ANSI/BHMA A156.3 standards. Because panic hardware is durable, secure, and easy to use, designers may specify its use even […]