Hello Readers! This is my next “Back-2-Basics” piece…if there is anything I should add/change, please leave a comment. And have a great week!

[Click here to download a printable copy of this article.]

The function of a door closer is not just to close the door; a good door closer will also control the door in both the opening and closing cycles to prevent damage and injury caused by abuse, wind, or other factors. With all of the available types and options, it can be difficult to know which closer to specify. Considerations include frequency of use, life-cycle cost, aesthetics, and the necessary features and functions. In addition, there are code requirements which must be taken into account.

During the opening cycle of a door, the closer’s function is to allow the door to open easily, except at the end of the cycle when backcheck is applied. The backcheck feature cushions the opening swing to prevent the door from hitting the stop with excessive force. An auxiliary stop should be provided as the backcheck feature does not replace the stop. For very abusive applications, the advanced variable backcheck option provides the cushioning effect earlier in the opening cycle. During the closing cycle, the closer should maintain a uniform closing speed until within a few degrees from the latch. In this position, the latch speed will ensure that the door closes firmly and latches, without slamming.

Considerations

Size / Durability – Door closers range from slimline closers to heavy duty closers, with other levels in between. Heavy duty closers are recommended for exterior doors, schools or public buildings where heavy use or abuse is expected, and high frequency doors. For doors that are used less frequently, a smaller closer may be acceptable and will typically cost less than a heavy duty closer.

Grade – The recognized standard for door closers is ANSI/BHMA A156.4, which details the testing requirements for grades 1, 2, and 3. However, most commercial and institutional closers meet the testing requirements for Grade 1 – from slimline closers to heavy duty, so specifying only the grade will not define the level of closer desired.

Material – Door closers are made of cast iron or aluminum. While aluminum closers can be a lower-cost option for some facilities, cast iron closers are preferred by many institutions because of the material’s compatibility with the high grade steel components within the closer. Where closers are subject to millions of opening and closing cycles, this durability is extremely important.

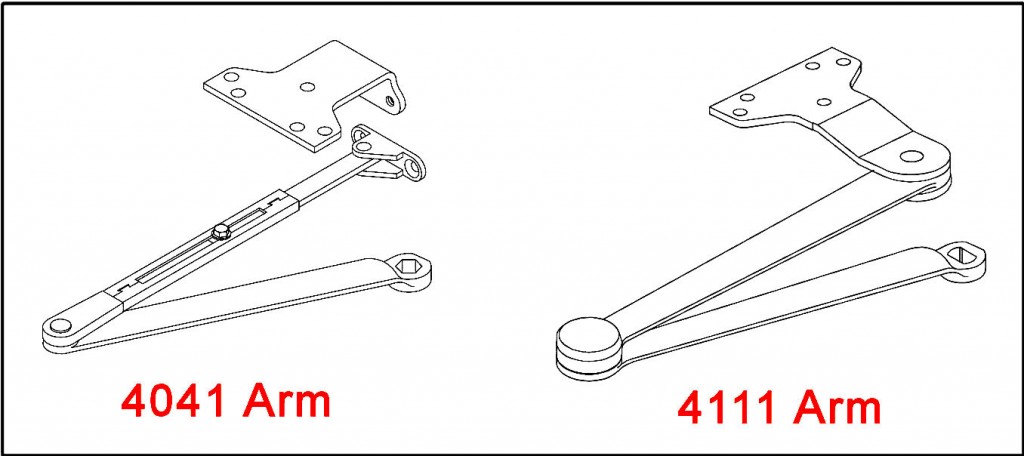

Type – There are two basic types of surface-mounted closers – application-specific and universal. Application-specific closers are designed to be installed in a specific mounting style and are “handed” – either left hand or right hand. A universal closer is more of a “one-size-fits-all” solution – the closer can typically be mounted 3 different ways, and on a door of either hand. While this may sound like the best product to specify, there are concessions. For example, the arm for an application-specific parallel arm closer is a solid arm, where the universal closer’s parallel arm is in pieces that are screwed together in the field. On a universal closer, the pinion penetrates the top and bottom of the closer, creating a second potential leak point, and the mounting location is in the hands of the installer since the closer can be mounted on the push side or pull side of the door. For institutional facilities, application-specific closers are recommended.

Type – There are two basic types of surface-mounted closers – application-specific and universal. Application-specific closers are designed to be installed in a specific mounting style and are “handed” – either left hand or right hand. A universal closer is more of a “one-size-fits-all” solution – the closer can typically be mounted 3 different ways, and on a door of either hand. While this may sound like the best product to specify, there are concessions. For example, the arm for an application-specific parallel arm closer is a solid arm, where the universal closer’s parallel arm is in pieces that are screwed together in the field. On a universal closer, the pinion penetrates the top and bottom of the closer, creating a second potential leak point, and the mounting location is in the hands of the installer since the closer can be mounted on the push side or pull side of the door. For institutional facilities, application-specific closers are recommended.

Arm / Function – The force of the closer is transferred to the door through the arm, so the construction of the arm is very important for the durability of the closer. Forged steel arms offer the maximum strength, where stamped arms are more commonly used when cost is the primary concern. Some closer arms can incorporate a hold-open feature, an integral stop (CUSH), a spring-loaded stop (Spring-CUSH) or a combination of hold-open and stop. For unusual applications, a special template may be needed. This template may illustrate a change to the mounting location, or a physical change to the closer (LCN has more than 3,000 special templates available!).

Spring Size – Most closers are adjustable in “size”, meaning that the spring power can be increased or reduced to control the closing force (this also affects the opening force). Closers that are not adjustable must be ordered in the correct size for the door opening, depending on the door size, whether the door is interior or exterior, or whether the location is particularly drafty. It is sometimes difficult to properly coordinate the functional requirements of a “sized” closer, with the opening force limits for accessibility.

Fluid – In addition to lubricating internal components, the fluid inside of a closer controls the closing speed as the adjustment valves increase or decrease the flow of fluid. Specifying a closer with all-weather fluid will eliminate the need for seasonal adjustments. Without all-weather fluid, a closer may creep closed slowly when it is cold, or slam shut when it is hot, because of the change in viscosity of the fluid with the change in temperature.

Fasteners – Proper fasteners should be specified and supplied depending on the door and frame material. Closers must be installed with manufacturer’s fasteners and per the manufacturer’s installation instructions and templates in order to function properly long-term. For mineral core wood doors, thru-bolts should be used unless special blocking is provided in the top of the door.

Finish – The powder coat finish available on many closers today is very durable, and is an environmentally-friendly process compared with other types of finishes. Powder coating can protect components for up to 100 hours of salt-spray testing, four times what is required by the test standard, and is available in standard and custom colors. For corrosive environments and exterior installations, a special rust inhibitor coating is also available. It may be tempting to specify closers plated with architectural plated finishes, but generally these finishes provide only a fraction of the durability offered by powder coating, and the plating process is very expensive.

Mounting Styles

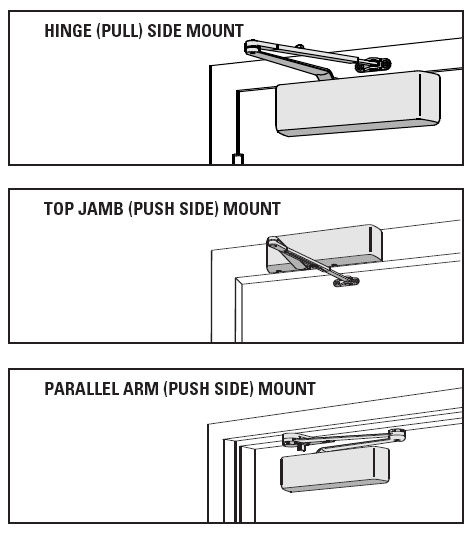

When selecting an application-specific closer, the mounting style must be considered. Surface-mounted closers are typically mounted where they are least visible to the public – ie. inside of a room instead of on the corridor side of the door. The most common mounting styles are:

Parallel Arm – closer is mounted on the push side of the door, with the parallel arm shoe attached to the underside of the frame head

Parallel Arm – closer is mounted on the push side of the door, with the parallel arm shoe attached to the underside of the frame head

Regular Arm (AKA Hinge Side Mount) – closer is mounted on the pull side of the door, with the arm attached to the frame face above

Top Jamb – closer is mounted on the push side of the frame, with the arm attached to the face of the door

Track Closers – various types available for push side or pull side mounting, with track mounted on door or frame and a single lever arm, instead of a double-lever arm and shoe

Concealed – may be used where aesthetics dictate, closer body mounted either in frame head or top of door

In addition to surface-mounted closers, there is a variety of other types of closers for specific purposes and applications. Floor closers may be desired when an overhead closer can’t be used. High security closers are designed for use where they may be subject to excessive abuse or vandalism. Closers with an electronic hold-open feature may be used to hold open fire doors, if they are integrated with the fire detection system so the doors close automatically upon fire alarm. Automatic operators are common for doors that need to provide greater accessibility than can be provided by standard door closers.

Code Requirements

Many codes and standards contain requirements for door closers. Accessibility, fire, and life-safety requirements all have an effect on door closers, but if the product is selected and installed properly, these requirements may not be difficult to meet.

Accessibility – According to the national accessibility standards, door closers must be adjusted so that it takes at least 5 seconds for the door to move from an open position of 90 degrees to 12 degrees from the latch. The delayed action feature, which holds the door open for a minute or two before beginning the closing cycle, is not required by the national standards but may be helpful for certain types of rooms such as a storage room or tub room.

Interior doors that are not fire doors must be able to be opened with a maximum of 5 pounds of force. This limitation applies to the force required to open the door, not the force required to release the latch. Fire doors are limited to the minimum opening force allowed by the Authority Having Jurisdiction (AHJ) – typically a size 3 closer is recommended by NFPA 80 for interior doors. Exterior doors are not addressed by the national accessibility standards, but may be addressed by state or local accessibility requirements. The International Building Code (IBC) limits the opening force for accessible, non-fire-rated, swinging doors to 5 pounds, and other egress doors to 15 pounds to release the latch, 30 pounds to set the door in motion, and 15 pounds to open the door to the fully-open position.

Fire Doors – One of the cardinal rules of fire-rated doors is that they must be closed at the time of a fire, but there are many ways to hold open a fire door. A wall-or floor-mounted magnetic holder and a separate mechanical closer may be used if the holder releases upon fire alarm / smoke detection. A closer with an integral electronic holder may either release upon fire alarm or may contain an integral smoke detector. For retrofit applications, a battery-operated holder with an integral smoke detector may be used in conjunction with a separate mechanical closer. According to NFPA 80, Standard for Fire Doors and Other Opening Protectives, a closing device must be installed on every fire door. A couple of exceptions to that requirement are communicating doors between hotel rooms, and the inactive leaf of pairs leading to rooms not normally occupied by humans, like a mechanical room (where acceptable to the AHJ). Closers must be securely attached with steel screws or through-bolts, and the closer must be adjusted so the door latches each time it closes.

Life Safety – The International Building Code (IBC) and NFPA 101 – The Life Safety Code contain similar requirements for holding open fire doors, although they are more specific with regard to locations where automatic-closing doors are allowed, and how they are released. Automatic-closing doors must have the capability of manual release, and be automatically released by smoke detectors meeting the requirements of NFPA 72 – National Fire Alarm Code. When automatic-closing doors are used on stairs, they must be wired so all doors close when one door closes, protecting the exit enclosure.

Life Safety – The International Building Code (IBC) and NFPA 101 – The Life Safety Code contain similar requirements for holding open fire doors, although they are more specific with regard to locations where automatic-closing doors are allowed, and how they are released. Automatic-closing doors must have the capability of manual release, and be automatically released by smoke detectors meeting the requirements of NFPA 72 – National Fire Alarm Code. When automatic-closing doors are used on stairs, they must be wired so all doors close when one door closes, protecting the exit enclosure.

Conclusion

For questions about door closers, assistance with special applications, or a complete specification, Ingersoll Rand Security Technologies has more than 100 specification writers and architectural consultants available to help. We are also an AIA/CES approved provider, and conduct a wide range of courses offering AIA continuing education units. For help with code compliance and product application, explore idighardware.com, where you can ask a specific question using the Help button.

You need to login or register to bookmark/favorite this content.

Lorie,

When a closer is at the end of its useful life and begins to leak (oil); should special care be taken when disposing of an oil filled closer. I’ve noticed many contractors simply throw them in the general trash. Is there a proper reclamation or recyling process that should be followed?

Thanks for all your wisdom.

Hi Dave –

That’s a really good question. I talked to LCN about it, and you can recycle the fluid as “used oil”. The closer bodies and arms can be recycled as scrap metal. You shouldn’t take the closer apart because of the spring inside (like those old practical joke toys that were a springloaded snake inside of a can, only a lot stronger!), but you should be able to back a valve out to remove the fluid.

– Lori

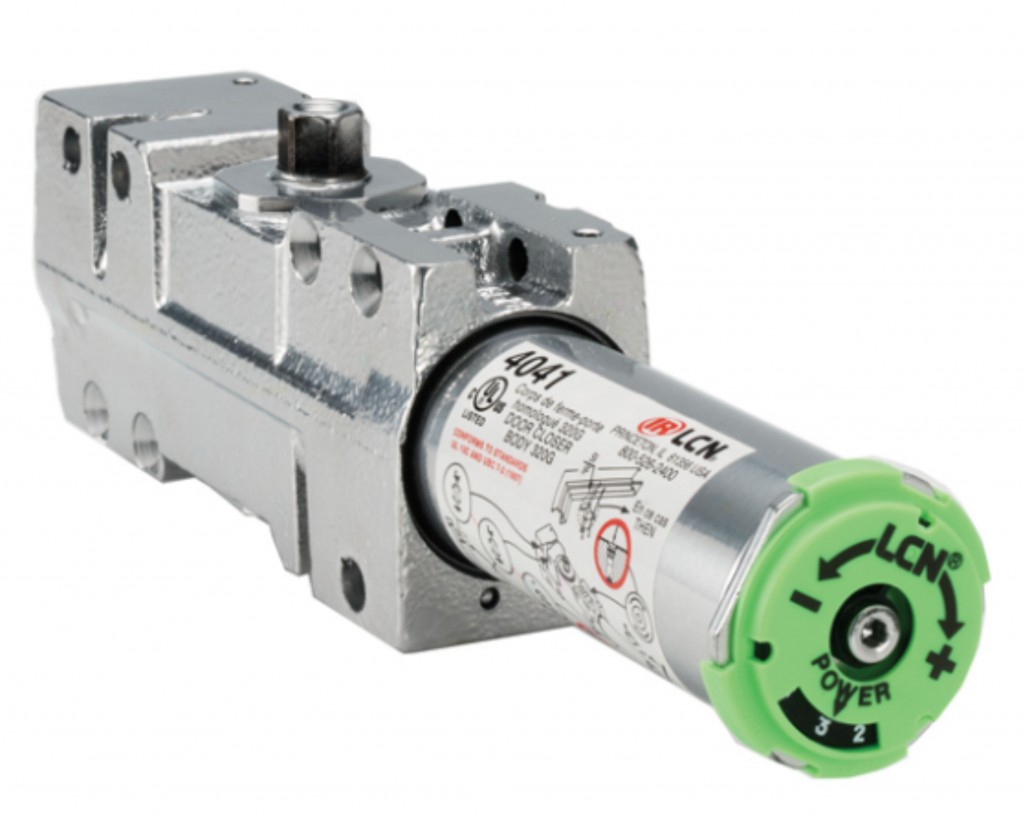

if going to back a valve out and its the 4041/4040 body, (both old and new body styles, best to use that valve on the back (backcheck selection valve) it is NOT staked, and you can remove it and with arm, let the fluid out by pumping the arm a few times to let the fluid out.

about the spring and getting a closer apart, there is a certain way to get them apart and not worry about the spring (the spring in a can joke as Lori explained) not only it risky, but most of them LCN’s will have a spring inside a spring which adds to the power, and be careful.

if you are familiar with the process, have the tools and want to take it apart, it is best done with spring tension set to 1 and remove the spring tube LAST take out pinion, piston (and fluid) first then the spring.

I will not dis”close” the process step by step as many in the door closer trade (New England Door Closer for instance, and LCN’s rebuild shop) want to keep the process a trade secret, even though a door closer is mainly a spring with a rack and pinion, and simple to understand but I want to respect the companies/factory and not give the trade secrets away

-Jess the door closer doctor

Hi Lori, I have been trying to find out if a door closer needs to display a fire rating label during FDAI. It’s understood that the closer should have done its job by the time the fire reaches the door but during FDAI training I have been told that all parts of a fire door assembly must have a label with the exception of steel ball bearing hinges. NFPA 80 states “items of a generic nature” do not need a label. Does a door closer fall under this category? I can find no clear answer on the labeling requirements. Do you have any additional info on this?

Hi Chad –

Yes, closers typically have a symbol designating the closer as a listed product. I added a photo of an LCN closer body to my post so you can see the UL mark on the label. I’m not sure you would want to remove the closer cover to check this during a fire door inspection…I think it’s pretty typical for commercial and institutional closers. Depending on how a closer is mounted, I’m not sure it’s always visible. Maybe I’m too lenient, but if the closer was working properly I wouldn’t check for each individual label unless it was a brand that I wasn’t familiar with.

– Lori

Back in the day I seem to recall a restriction as to when Back Check takes effect when mounting a closer in the PA position. can you refresh my memory?

I have a cast iron closer. Don’t know the brand name. Door slams shut. I don’t see any external adjustment screws.It has no visible oil leaks.

Is there a bad seal inside and can I unscrew the plug at one end to take it apart or whats wrong ??? thank you….

Hi Wolf –

I wouldn’t recommend unscrewing it – the spring inside is under pressure. If you email me a photo I’ll see if I can get you some help.

– Lori

lori.greene@allegion.com

If there are no valve adjustment screws on the outside of the closure visible, does that mean that it is the fixed style and is worn out ???

thank you: wolf

I don’t know for sure but I might be able to tell if you send a photo.

– Lori

lori.greene@allegion.com

If anyone is interested in viewing the internals of floor closers, including some Victorian era models please view the gallery of my site here http://www.midlandsfloorsprings.co.uk/gallery.html

I will be mounting a universal closer on a residential exterior garage door (fiberglass) that is exposed to high wind. Of the 3 mounting choices is one preferred over the others for function, or is it simply a matter of personal choice for aesthetics? The door is out-swing from garage to a breezeway and will need to have 150 degrees of swing to contact the stop.

Hi Dave –

I think regular arm is probably the most efficient, with top jamb second and parallel arm the least efficient, but I doubt it would make that much difference in your situation. If you can wait until Monday, LCN Engineering department can give you a better answer. Not all mounting configurations will allow the door to open 150 degrees, so that might help you choose. I always mount the closer where it won’t be exposed to the weather.

– Lori

Hey Lori,

What exactly does “CUSH” mean? I’m trying to find a door closer that would work well on offshore oil platforms. The LCN 4116 seems to work well, but I’m trying to make sure it will not slam shut under too high winds or due to suction when another door in the same building is opened. Is CUSH a delayed closing?

Thanks for your help!

Cat Nix

Hi Cat –

A CUSH closer has a built-in stop to stop the door in the fully-open position. It might help in high winds to keep the door from slamming open into the wall, but it won’t help prevent the door from slamming shut. There is a delayed closing option (called “delayed action”) but I don’t think that will really help you either – in high winds it will probably leave the door standing open. If opening force is not an issue (for accessibility), then I think the 4116 is your best bet – it should control the door well. If you’d like me to ask my readers for their advice, send me a photo and description of the type of door problem you’re trying to solve and I’ll ask the masses.

– Lori

Hey Lori,

Thanks for the quick reply! The problem of the door slamming shut is one that has happened before, but I don’t know if it has happened with the 4116. I just am trying to make sure it doesn’t ever happen. Thanks for answering my question! In the event that a door slams with an LCN 4116 on it on my watch, I will submit my question to the masses.

Thanks again!

Cat Nix

Ok – let me know!

I’ve got a noisy door closer, which makes a groaning or moaning sound as it is pulled open and closed. Looking on various sites, I am guessing the problem is either a damaged o ring on one of the valves or a lack of oil.

It’s a briton 2003v and is brand new, no leaks. I can only back the valves off so far, as there is a plate that stops the screws coming out all the way… I tried adding oil with them backed off as much as possible but didn’t have time to let it drain in (if it would do that)

Any pointers on what to do next?

Hi Jeff –

I talked to my US coworkers about this but we don’t have specific information about the Briton products. Have you tried talking to Briton customer service?

– Lori

Hi Lori,

Thanks for answering – I’ve just asked them… didn’t think of that!

Thank you!

Best, Jeff

I’m looking for a door closer to handle a custom steel and glass door. Roughly 200 lbs. It needs to be top jamb push side out (closer is on the inside top jamb and door pushes out). To take into consideration, the jamb is 6 inches so the arm needs to be adjustable to reach the door. I have used HD standard closers – always the latch swing makes the door slam. I need a closer that can handle the weight and control the final latch without letting go. Tks

Hi Bob –

Have you tried the LCN 4021? For a reveal up to 4 13/16″ (between the face of the frame and the face of the door), the standard arm will allow 140 degrees of opening. If you could mount the closer parallel arm, you could use the LCN 4111 – possibly with a Spring-Cush arm. The door will need to have some sort of stop either way.

– Lori

The true question is will these hold the door from slamming? The stop you refer to is?

A good quality closer should control the door, and if adjusted properly it will keep the door from slamming. The stop that I referred to will stop the door in the fully-open position and protect the opening.

– Lori

Thank you lori. Your help was extremely valuable and cannot thank you enough.

Note: for all LNC closers.JAM MOUNTED (push side) you will need a back plate so the closer can be lowered which is NOT included.

Once again Thank You.

Thanks Bob! The drop plates aren’t always required, but if the frame face or the top rail on the door are too small, yes – you will need a drop plate. I hope it works out for you.

– Lori

I need a closer on a 36″ steel door that is not in heavy use, but opens to the outside which is often windy. I have been looking for a description of how heavy-duty I need the opener to be, but nothing seems to tell me what criteria to use, or how to evaluate the differences between models for my needs. Any help would be appreciated. Thanks

Hi Mitch –

For an exterior outswinging door in a windy condition, I would recommend an LCN 4111-S-Cush. This is a very durable model, but if you need something less expensive there are other options.

– Lori

Hi Lori,

I’m creating a desk reference of the “basics” for myself. I’m having difficulty printing this one. Do you have it saved by chance in PDF format anywhere easy to get your hands on? Thank you either way!

Hi Cecilia –

I just uploaded a printable copy to the post.

– Lori

Hello Lori,

Thanks for all this great info. I emailed you but will also comment here. I am looking to get a Therma-Tru S118 fiberglass door (glass door with fiberglass frame). Do you know if I can install a door closer on a fiberglass door? Any recommendations being this will be a exterior out swinging residential door?

Thanks,

Josh

Hi Josh –

Have you talked to the door manufacturer? I’m not familiar with this particular door…most commercial doors that will have a door closer installed have a closer reinforcement built in. Since this is a residential door, there are some light-duty closers that might work if thru-bolts are used and/or if the door is reinforced.

– Lori

Thanks, Lori. Yes, door manufacture said reinforcement is recommended but is $169 for just backing reinforcement. I am considering a wood door in order to have more strength. If going with a wood framed glass door would you recommend a different closer model?

Thanks,

Josh

Hi Josh –

I would just check the closer manufacturer’s information to make sure the closer will handle the door size. I work with commercial products which are probably more than you need (or want to spend) for a closer on a residential door. Most of these closers would have to be purchased from a door hardware supplier so depending on where you’re planning to buy the closer you might be limited as to which products they have available. In the LCN product line, you could use the 1250 or 1260 series: http://us.allegion.com/IRSTDocs/Catalog/109508.pdf.

– Lori

I have a LCN 4011 Smoothee-Heavy Duty Institutional Adjustable Door Closer with hold open. I’m trying to adjust the hold open and can’t find any information. Can you help.

Hi Jeff –

There’s a short description of how to adjust the hold-open on these installation instructions (near the top of the first page on the right): http://us.allegion.com/content/dam/allegion-us-2/web-documents-2/InstallInstructions/LCN_4010_Series_Installation_Instructions_107166.pdf. If that doesn’t help, LCN Tech Support should be able to walk you through it. The phone number is 888-981-6709.

– Lori

As i opened a back door, a gust of wind blew it open beyond its limits. The 4041 door closer clicked a couple of times and now the door won’t close because the arm hits the door as it tries to close. is there a way to fix or adjust the closer? thanks

Does anyone make a closer with a lot of force over the last few degrees of travel without having to depend on closing speed or momentum? I’m thinking some kind of internal cam to multiply the force in the last few degrees to assure a latch.

We have external doors on a commercial building with a seal between them which causes a good deal of friction when closing over the last inch of travel. The seals in this case are not something we can adjust, replace, or modify. The building maintains a small positive pressure which further forces the doors open.

The problem is that we cannot find closers that have a reasonable amount of overall resistance for a person pushing through and also enough force to close the door when the seals rub. The doors tend to remain unseated unless they are pulled all the way shut. This is a problem for the mag locks and building ventilation.

Door closers are an important feature in commercial/office buildings. Manual door closers are used to shut exterior doors automatically without the use of electricity. They are installed for two major reasons. First, door closers are a security feature because they ensure that doors close whether human force is applied or not. Second, they help ensure that fire cannot spread from one part of a building to another or from one building to another during a fire emergency. A secondary reason to install door closers is to keep indoor air inside and outdoor air and weather outside.

The doors in your house are usually very different in many ways from the ones you see at an office or a factory. While both are installed for security reasons, the commercial one needs to be fortified in order to withstand constant usage. Installing the wrong doors on your commercial complex could cost you a lot of money in the case of an emergency. Security is just one way the wrong doors can cost, to save on utilities you also need to invest in door closers. This is an important aspect that will ensure security, looks professional and reduces the cost of heating and AC, as well.