The other day I posted a video of a webinar about the clearances around fire doors and the effects of those clearances on the performance of the assembly. The webinar is an hour and a half long, so I’ve summarized some of the points below. I recommend watching the entire video so you don’t miss anything, especially if you’re interested in the details of the research conducted.

NFPA has been studying how the clearances around a fire door affect the door’s ability to limit the passage of smoke and fire. Some clearance is needed in order for the door to function properly, but how much clearance is too much? Inconsistent floor levels can result in more clearance at the bottom of the door than what is allowed by the NFPA 80 standard, and perimeter clearances can be inconsistent depending on the installation of the frame.

Prior to the 1960’s, NFPA 80 limited the clearance at the bottom of a fire door to 3/8-inch, which matched the clearance that is used during the test for fire doors; the current test standards still use 3/8-inch clearance for fire doors during the test. The 1966 edition of NFPA 80 was modified to allow 3/4-inch of clearance at the bottom of the door, and 3/8-inch of clearance between the bottom of the door and a raised sill, with no prescriptive information about the height of the raised sill. The 1999 edition of NFPA 80 included varying clearance dimensions at the bottom of the door, depending on the type of flooring material that was installed. Keep in mind that the clearance is different from the undercut (more info on that here).

In the 2007 edition of NFPA 80, the maximum clearance dimension was changed to 3/4-inch regardless of the type of floor material, and 3/8-inch for doors with a raised sill – clarifying that this 3/8-inch limit applies to doors with a sill located 38 inches or more above the floor. An example of this would be the door leading to a trash chute or laundry chute. For these doors, the clearance at the bottom can not be more than 3/8-inch. This makes sense because with the bottom of the door at that height there is increased pressure forcing smoke and flames out through the gaps.

For typical doors without a raised sill the maximum clearance at the bottom of the door is 3/4-inch, which is measured between the bottom of the door and the top of the flooring or threshold. This clarification regarding the clearance at the bottom of the door is an important one, as there has been some confusion about how the clearance should be measured. The way I understand this requirement, if a fire door assembly without a threshold has more than 3/4-inch of clearance, a listed threshold could be added to reduce the amount of clearance. However, if there is latching hardware at the bottom of the door (like fire exit hardware with a bottom latch), the templates for that product may establish a required clearance less than 3/4-inch.

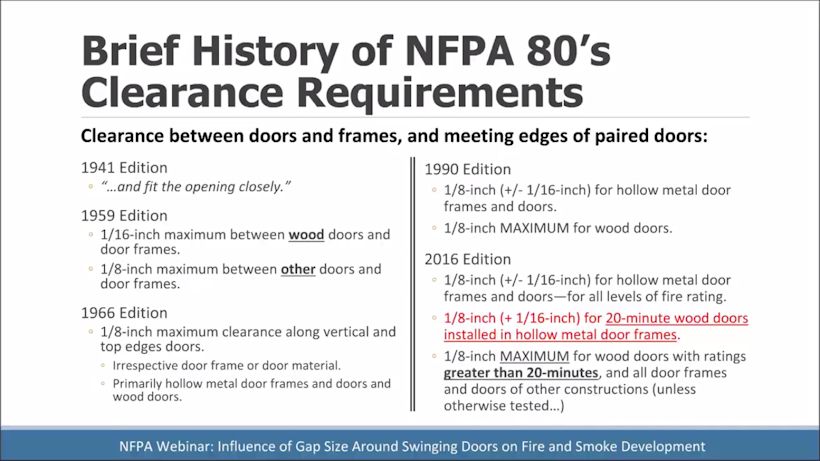

The clearance dimensions at the head, jambs, and meeting stiles have changed a bit over the years:

Most of you are probably familiar with the required clearance at the head, jambs, and meeting stiles, as these requirements have been in place for many years and are still one of the most common deficiencies found during a fire door inspection. But you may not have noticed that there was a change in the 2016 edition of NFPA 80, which will be referenced by the 2018 model codes. Prior to this edition, a 20-minute wood door in a hollow metal frame was limited to 1/8-inch clearance at the head, jambs, and meeting stiles. The 2016 edition of NFPA 80 allows up to 3/16-inch clearance for 20-minute doors in hollow metal frames. While adding 1/16-inch is not a huge difference, it will help with doors that are just slightly over the 1/8-inch clearance required by previous editions of the standard. Note that this edition of the standard is technically not applicable unless referenced/adopted.

The webinar discusses the procedures used for testing fire doors, and the research that was done in order to determine whether larger clearances should be acceptable. Test standards from other countries were studied, as well as computer modeling and actual fire tests on doors and the reasons for failures that occurred during these tests. But the questions remain…is this the optimal amount of clearance? Would more clearance negatively impact the performance of the assembly? How do manufacturing tolerances factor into this equation? Does intumescent material mitigate large gaps by filling that space during a fire? Do the optimal clearances vary depending on the door material?

Further study will help the NFPA 80 Technical Committee decide whether to modify the clearances in future editions of the standard. It sounds like the next step will be full-scale testing to study not only the smoke and flame transmission through the gaps, but also the performance of the latches and other aspects of the assembly.

There is a Q&A period starting at the 1:17:00 mark in the video, which in my opinion is the best part. 🙂 They ran out of time to answer all of the questions, so I have requested a copy of the follow-up Q&A document and I will post it here if/when I receive permission.

You need to login or register to bookmark/favorite this content.

The threshold is supposed to be non-combustible, right? How do all these hotels get away with those vinyl transition strips that originally came from DHSI and then copied by Pemko, V232? You need about 1 1/8″ undercut to work with these and an automatic mortise door bottom – even more undercut if using a door shoe like the 2343. Once all that carpeting and vinyl melts and burns, you have quite a gap under there.

NFPA 80 doesn’t say a whole lot about the flooring, although there are flame-spread requirements for flooring that would also apply to a vinyl threshold. The good news is that the smoke and flames are usually pushed out at the top of the door – not at the bottom.

– Lori

Lori,

where can I find building codes and fire codes that pertain to classroom doors.

Are there specific codes that apply to NYC public school classroom doors?

Any suggestion on how a civilian can propose a code change?

Thanks,

DOm

I would appreciate if you can also reply via email

Hi Dominic –

The NYC Fire Code is here: https://www1.nyc.gov/site/fdny/about/resources/code-and-rules/nyc-fire-code.page

The NYC Building Code is here: https://www1.nyc.gov/site/buildings/codes/2014-construction-codes.page#bldgs

In Chapter 10 of the building code, refer to sections 1008.1.9 including 1008.1.9.5.

– Lori