C learances in excess of those allowed by NFPA 80 are one of the most common problems with fire door assemblies, and can be very difficult to resolve. National Guard Products has just released two new UL Certified accessories for excessive fire door clearances, which will help to bring many of these doors into compliance. The catalog pages can be downloaded here and list prices are available on the NGP product pages (click images on the right).

learances in excess of those allowed by NFPA 80 are one of the most common problems with fire door assemblies, and can be very difficult to resolve. National Guard Products has just released two new UL Certified accessories for excessive fire door clearances, which will help to bring many of these doors into compliance. The catalog pages can be downloaded here and list prices are available on the NGP product pages (click images on the right).

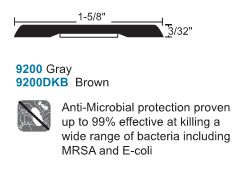

NGP-Edge Intumescent Fire Seal (9200) can be used at the head and jambs when clearance measures between 1/8 inch and 5/16 inch. The self-adhesive seal is listed for use on 20-minute rated UL10B and UL10C wood or hollow metal fire doors (including the hose stream test required for 20-minute doors in Canada). The product can be mounted on the door edge or on the frame rabbet depending on aesthetic preference. An NGP strike shim is also required for proper latchbolt engagement.

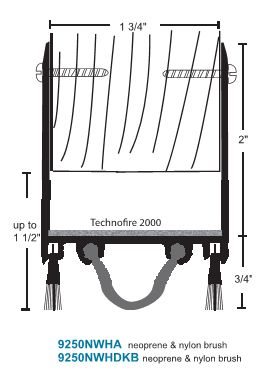

NGP-Edge Intumescent Door Shoes (9250) can be used to address excessive clearance measuring up to 1 1/2 inch at the bottom of the door. It is listed for use on 20 minute rated UL10B and UL10C wood or hollow metal fire doors, and restricts the passage of smoke with a variety of gasketing combinations including nylon brush, neoprene, vinyl, and thermoplastic.

NGP-Edge Intumescent Door Shoes (9250) can be used to address excessive clearance measuring up to 1 1/2 inch at the bottom of the door. It is listed for use on 20 minute rated UL10B and UL10C wood or hollow metal fire doors, and restricts the passage of smoke with a variety of gasketing combinations including nylon brush, neoprene, vinyl, and thermoplastic.

Roger Skold is the Technical Director at NGP, and he answered my questions about these products. Here is a summary:

Is the edge seal material applied only where there are oversized clearances? Yes, the material is only installed where the oversized clearance exists. For example, if the problem is only at the head, the intumescent seal is installed at the head where the clearance is excessive, and the jambs are left as-is.

What happens at hardware locations – ie. a mortise lock? Does the installer mount the intumescent above and below the lock? Yes, it was tested as follows: jamb mounted – above & below a 4-7/8” lock strike, door mounted – above and below an 8” mortise lock face. Excessive clearance is less likely at the hinge edge, but the product can be used on the hinge jamb if necessary, and can be stopped above/below each hinge.

Is there any information available about the lifespan of the adhesive? It is a tackified acrylic and basically once bonded is considered permanent. The “shelf life” prior to installation is more important and is recommended as 1 year (will slowly degrade after that).

Can the intumescent edge seal be used at the meeting stiles of pairs? The product was tested on single doors, so use at the meeting stiles would be subject to acceptance by the Authority Having Jurisdiction (AHJ).

Is the fire seal available in other colors besides gray and brown? Other colors may be available on request, and the product can also be field-painted.

Do these products create an egress problem after the intumescent is activated? The intumescent activates when it reaches 375-400 degrees F. Because the intumescent is protected by the door/frame, the temperature in the test furnace is over 1,000 degrees before it intumesces, and egress is not an issue at that point. The door is not required to be usable for egress after a fire / fire test, but the soft puff graphite used in this intumescent probably would not prevent the door from being opened.

If the door is required to comply with the limitations stated in the code when tested to UL 1784, is smokeseal required in addition to the fire seal? Yes, a Category H listed smokeseal for Smoke and Draft Control would be required.

If you have additional questions, leave them in the comment box and I will discuss them with Roger and update the post.

You need to login or register to bookmark/favorite this content.

Thanks for the research and communication Lori, and thanks to mfgs for starting to fill this product void!

I haven’t forgotten about your roller latch question. It’s on the list!

Thank You Roger and Lori,

For side and top jamb clearances; what are the maximum clearances that can be addressed?

For larger gaps can it be used on both the door and the jamb?

How would you address if the clearances vary from top to bottom for side jambs and side to side on head jambs?

Hi Dave –

The maximum gap to be addressed with the edge seal is 5/16″. The testing didn’t include installing it on both the door and the frame to handle a larger gap. If the clearance varies, you would install the seal where the clearance is larger than 1/8″ (or larger than 3/16″ for hollow metal doors). Anything beyond 5/16″ would have to be discussed with the AHJ as it is not covered by the UL listing.

– Lori

Hi Lori. Two questions: Is the intumescent (not the adhesive) effective over over time, so that years after installation if we see the intumecent in the opening can we be sure it will perform properly in a fire?

Next question is about the 20 min rating. Intumecents are used successfully on 2 hour BS476 fire doors, and the time/temperature curve is about the same as UL10c. Can NGP share the reason they stopped at 20 minutes? 45 would be really nice.

Thank you again for all this great work!

Lloyd

Hi Lloyd!

I’m sorry – your question and another one (along with my answers) didn’t post properly and I didn’t notice it until now. I asked Roger at NGP about your questions. He said that the intumescent is graphite-based and doesn’t really deteriorate with age. It’s protected by the PVC so I think if you don’t see damage to the PVC, then the intumescent should still perform properly. In the door shoe, it’s a different type of intumescent but again it’s not prone to deterioration and it’s protected by the shoe. It’s the same type of intumescent that’s used in some Category A wood doors, and in some cases it is exposed in the top edge of the door without a problem.

Regarding your second question, the intumescent has been successfully tested for a longer duration, but the hose stream is a problem. NGP felt confident about the 20-minute test and also included the hose stream for Canada. According to the UL engineers, the results were as perfect as you can get, so there may be a longer test done in the future. Because of the different door construction (solid core vs. mineral core), the tests would have been run separately anyway.

– Lori

Thank you Lori. I’m looking forward to seeing the solution for 90 minute openings.

If NGP can share any more information about the efficacy of the intumescent over time I’d appreciate it. It’s interesting to note that UL1479, the standard for sealants used in firestop penetrations, added an accelerated aging test in 2006 to address this issue. We don’t have that requirement in UL10B or C so it’s not something we can rely on without additional information.

-Lloyd

Could you please clarify the difference between a UL Listed and UL Classified product as it pertains to door bottoms, door sweeps and gasket.

Thank you

Hi Bob –

I apologize – I just realized that your question and one other (and my answers) didn’t post properly. I talked to Roger at NGP about your question, and he said that currently some products are classified (like gasketing), while doors and other products like lite kits are listed. UL is in the process of changing to new marks which use the term “certified” to replace both the classified and listed terminology. There’s more information about UL marks here: https://markshub.ul.com/.

– Lori

Hi Lori,

1. When reviewing the NGP 9200 the first assumption is that it decreases the excessive clearance to 1/8″ or less to come in compliance. It could be confusing to AHJ’s or end users that its purpose is not such and the gap may still exceed 1/8″ (ie. 5/16″ gap less 3/32″ 9200 = 7/32″ remaining gap). If I understood that correctly is there anything in writing that will help others understand this?

2. In reviewing the NGP picture of the frame application, the 1-5/8″ wide 9200 would not leave sufficient space for typical 1/2″ or 3/8″ smoke seal installation (which would likely already be installed when the dilemma is discovered)?

3. Presuming my assumption on questions 1 and 2 are correct why did they not test this scenario using the 9500×2525 which is similar, has intumescent, smoke seal and is rated for 20, 45, 60 & 90min?

Hi Michael –

I’ll pass your questions on to Roger at NGP and post the answers asap.

– Lori

Hi Michael –

Here are Roger’s answers:

Question 1: When reviewing the NGP 9200 the first assumption is that it decreases the excessive clearance to 1/8″ or less to come in compliance. It could be confusing to AHJ’s or end users that its purpose is not such and the gap may still exceed 1/8″ (ie. 5/16″ gap less 3/32″ 9200 = 7/32″ remaining gap). If I understood that correctly is there anything in writing that will help others understand this?

Answer 1: UL Certification answers this. It states “for excessive door and frame clearances when installed per the manufacturer’s instructions” – the instructions state: “For use on 20 minute UL10B and UL10C wood or hollow metal fire doors with head and or jamb clearance exceeding 1/8”, up to 5/16”. This message is also on the catalog page right at the top headline.

Question 2: In reviewing the NGP picture of the frame application, the 1-5/8″ wide 9200 would not leave sufficient space for typical 1/2″ or 3/8″ smoke seal installation (which would likely already be installed when the dilemma is discovered)?

Answer 2: An excessive gap at the lock jamb or head will allow the application and installation of 9200 to either the door or frame without interfering with a stop mounted silicone teardrop bulb smoke gasket. Other installations may need to change to stop mounted teardrop smoke seal. The hinge jamb typically will not have excessive gap as the hinges won’t allow it. If it is somehow the 9200 can be mounted and a silicone teardrop smoke seal can be added and stop mounted to avoid conflict.

Question 3: Presuming my assumption on questions 1 and 2 are correct why did they not test this scenario using the 9500×2525 which is similar, has intumescent, smoke seal and is rated for 20, 45, 60 & 90min?

Answer 3: 9500 and 9200 intumescent properties are different. Also, see response to question 2.

Has anyone found a product for an excessive bottom gap of fire rated wood doors rated above 20 minute? (without adding a threshold)

I have found one for HM doors but not for wood. Thanks!

Hi Rob –

How about the Crown product? http://crownfiredoorproducts.com/products/wood-door/fire-door-extension/

– Lori

Yes, perfect. I called the folks at Crown Fire Door and they have what I was looking for = solution. Thank you for the link Lori!

Lori: Based on previous comments you have made as well as section 7.4.3.1.1 & 7.4.3.1.2, NFPA 80-2010 anything that gets installed on a fire door should (must?) be labeled. Consequently I am dumbfounded that NGP is manufacturing Door Bottom Shoes (NGP 9245 for 45-min doors) and Door Bottom Systems (NGP 9590 for 90-min doors) as well as other door gap devices, yet none of them are labeled. Yes they are listed but they are not labeled with anything to identify them. What are your thoughts?

Hi Rodney –

These products would have to be listed, but NFPA 80 has an exception for the actual labeling for certain items. The NFPA 80 Handbook says this:

For swinging doors with builders hardware, each hardware component is required to have its own label. These types of labels can be an embossed emblem (e.g., F, f, and Ff or the UL mark) or a type of applied label. Some models of hinges will bear an embossed label that is visible when the hinges are opened. Other models of hinges do not have an embossed label, but they do carry an official listing from one of the testing labs and are manufactured in compliance with Table 6.4.3.1. Gasketing is another product that might not have an actual label attached to it, due to the design and shape of the product. In this case, the packaging of the gasketing material will bear the label. Like the unmarked hinges, unmarked gasketing products are listed by the testing labs.

– Lori