This post was published in Doors & Hardware

Oversized clearances are one of the most common deficiencies found during the annual fire door assembly inspections that are required by current codes. Prior to the 2016 edition, NFPA 80 – Standard for Fire Doors and Other Opening Protectives limited perimeter and meeting stile clearance to a maximum of 1/8 inch +/- 1/16 inch for steel doors and 1/8 inch for wood doors, when measured on the pull-side face of the door. Beginning with the 2016 edition this was modified slightly to allow 20-minute doors (including wood doors) in hollow metal frames to have a maximum clearance of 1/8 inch +/- 1/16 inch. These clearances can be difficult to maintain, especially at the meeting stiles of pairs.

Oversized clearances are one of the most common deficiencies found during the annual fire door assembly inspections that are required by current codes. Prior to the 2016 edition, NFPA 80 – Standard for Fire Doors and Other Opening Protectives limited perimeter and meeting stile clearance to a maximum of 1/8 inch +/- 1/16 inch for steel doors and 1/8 inch for wood doors, when measured on the pull-side face of the door. Beginning with the 2016 edition this was modified slightly to allow 20-minute doors (including wood doors) in hollow metal frames to have a maximum clearance of 1/8 inch +/- 1/16 inch. These clearances can be difficult to maintain, especially at the meeting stiles of pairs.

For most fire doors, clearance at the bottom of the door is limited to 3/4 inch above the finished floor. This clearance is measured from the bottom of the door to the top of the flooring or threshold. If the bottom of the door is more than 38 inches above the finished floor, the maximum clearance is 3/8 inch or as specified by the manufacturer’s label service procedure. An example of a door that would require a maximum 3/8-inch clearance at the bottom would be a chute door or counter shutter. The reason the requirement differs from the 3/4-inch limit for doors with the sill below 38 inches is because of the location of the neutral pressure plane during a fire or fire test, and the behavior of smoke at that location.

Some clearance problems can be addressed by shimming a fire door’s hinges with steel shims, installing a threshold (maximum 1/2 inch high for doors on an accessible route), or adding an edge guard or door bottom that is listed for this purpose. It’s a common misconception that any listed gasketing products can be used to bring a door with oversized clearances into compliance. While many products in a gasketing manufacturer’s catalog may be listed for use on fire door assemblies, only a few have been tested and listed for the purpose of addressing clearances beyond what is allowed by NFPA 80. The vast majority of listed products must be used on fire doors that have code-compliant clearances.

Rectifying clearance problems can be difficult and costly, so it may be tempting to leave non-compliant doors in place and assume that a little extra clearance won’t affect the performance of the fire door assembly; I can now say from first-hand experience that this is not true. I was invited to attend a fire test at Underwriters Laboratories (UL) by Courtney Noble of Crown Fire Door Products (manufacturer of the tested products) and Chuck Noble of Certified Fire Door (the company responsible for the research and development of the tested products). The wood doors tested had variable clearances from 1/8 inch to 1/2 inch, and the clearance at the bottom of each door was 3/8 inch.

The Crown Fire Door Stop was installed at the perimeter to address the clearance issues at the head and jambs, and the doors were tested per UL 10C – Positive Pressure Fire Tests of Door Assemblies. Although the UL listing was achieved for 3-hour rated steel doors with clearances of up to 1/2 inch, the Category A wood door developed visible flaming at the top of the lock edge and did not pass the test. It was very disappointing to see the wood doors fail, but it was valuable evidence that existing wood doors are unlikely to perform as designed and tested in a fire situation if the clearances are not compliant with NFPA 80.

I attended a second test of these products at UL earlier this year, with several design changes and positive results! In addition to perimeter clearances up to 3/8 inch, the bottom of the doors in the second test had a 2-inch undercut – much larger than the 3/4-inch limit imposed by NFPA 80. Several system components were installed in addition to the fire door stop – steel channels across the top of the wood door to protect this vulnerable area, at the bottom of the door to reduce the clearance, and a full-height channel on the lock edge. In addition, the Crown Latch Protector was installed under the strike to ensure that the latch was properly engaged even with the excessive clearance. Both the Category A and Category B wood doors successfully passed the test and the tested products achieved a listing for use on wood doors rated for up to 90 minutes.

Two representatives from the International Fire Service Training Association (IFSTA) were on hand to document the test for future use in their instructional publications for the fire service, and have generously allowed the use of their photos here.

The installed Category A and Category B wood doors are examined by Chuck, Courtney, and Uriah Noble, Michael Nicasio of UL, and Dan Hibbs of Eggers Industries.

The Crown Latch Protector installed behind the strike is used as part of the system to ensure sufficient latch engagement.

The masonry wall with two fire door assemblies ready for testing is moved into position adjacent to the furnace.

Testing begins. Three thermocouples remain attached to the face of each door for the first 30 minutes of the fire test.

Inside the furnace the doors can be seen on the left, with the remnants of the veneer visible around the edges of the exposed core.

A cotton pad is used to ensure that there is not sufficient heat/flame transfer to ignite combustibles on the non-fire side of the fire door assembly.

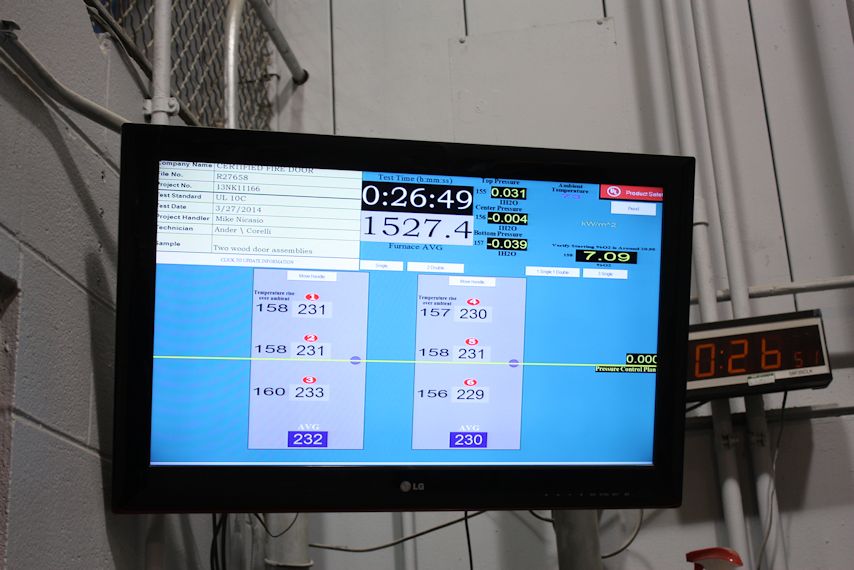

Monitors report the test progress – at 27 minutes into the test, the average furnace temperature was more than 1500 degrees, but on the non-fire side we could stand directly in front of the doors – evidence of the protection fire doors provide.

The Schlage L9000 series lockset remained latched throughout the test as required, although the furnace-side levers melted off as expected. Operable hardware is not required to be functional after the test.

For a 90-minute rated door, the hose stream test is conducted in a pattern across the surface of the door, at 30 psi for 1.5 seconds/square foot.

Because a method for addressing excessive clearance is not currently included in NFPA 80, section 1.5 – Equivalency should be referenced for guidance. NFPA 80 does not prohibit the development of new devices that meet the intent of the standard. Information from the testing laboratory is available for review and approval by the Authority Having Jurisdiction (AHJ).

Photos courtesy of Leslie Miller, Fire Protection Publications.

You need to login or register to bookmark/favorite this content.

I notice that the test doors open INTO the furnace. Are fire tests ever conducted with the doors opening OUT from the furnace? And if not, why not?

That’s a really good question. I looked at the NFPA 252 test standard, and it says:

5.2.1 Swinging doors shall be mounted to swing into the furnace chamber.

5.2.4 Access-type door assemblies and chute-type door assemblies shall be mounted with one door arranged to swing into the furnace chamber and another door arranged to swing away from the furnace chamber.

5.2.7 Surface-mounted hardware (fire-exit devices) for use on fire doors shall be evaluated under conditions where it is installed on one door arranged to swing into the furnace chamber and on another door arranged to swing away from the furnace chamber.

That strike shim looks horrible, I know I could stack 3 strikes and make it look better than that.

Hello, Bryan.

The Latch Protector (strike shim) does look rough. It is a prototype and was handmade for the test, along with all the tests products.

The latch protector you see has rounded corners. The new design has squared edges and looks like it was made for the strike.

The Latch Protector will be made with 1/8″ thick steel, primed, and to the dimensions of the strike prep. As far as I know, it is the only approved product for the latch penetration issue.

Stacking strike plates is not an approved way to bring back the 1/2″ penetration requirement, because the hardware companies have not tested the striker plates for that purpose.

Thank you for commenting on our product. It makes us better!

Best Wishes,

Chuck Noble

What if you have a 90 Minute wood door with a rim exit device- do you order the strike side piece without a cut out?

Hi Jefferey –

Yes, in this situation the strike jamb would not normally have a prep for a strike, but it may be reinforced for the strike.

– Lori