This post was published in Doors & Hardware

Each of the codes and standards that we typically refer to for requirements pertaining to door openings contains slightly different language regarding mounting heights of operable hardware. Generally, hardware must be mounted between 34 inches and 48 inches above the finished floor or ground, with exceptions for (a) locks used only for security purposes, and (b) operable hardware on doors leading to swimming pools. But it’s important to understand how the standards differ, in order to fine-tune the requirements for a specific project depending on the code or standard in use.

The International Building Code (all editions to date) requires operable hardware for most egress doors to be mounted between 34 inches and 48 inches above the finished floor (AFF). Locks used only for security purposes and not used for normal operation are excluded. Beginning with the 2006 edition, there is an exception for doors and gates leading to swimming pools, spas, and hot tubs – release devices for operable hardware may be mounted at 54 inches maximum above the finished floor.

The language pertaining to “locks used only for security purposes” isn’t very specific, which leaves this up to interpretation by the Authority Having Jurisdiction (AHJ). The IBC Commentary gives the example of an unframed glass door at the front of a tenant space in a mall, with a lock in the bottom rail. Deadbolts mounted at other heights may be accepted by the AHJ, depending on the occupancy type.

The exception in the IBC for pool doors is meant to address the requirements in some codes which call for pool doors and gates to have latching hardware mounted between 48 inches and 54 inches AFF so that a small child can not operate it. Check your state or local codes to determine whether doors to indoor pools require a special mounting height or if there are other requirements for this hardware.

The ICC standard A117.1 – Accessible and Usable Buildings and Facilities (2009 and 2017) contains virtually identical language to the first paragraph from the IBC, although it does not currently include an exception for swimming pool doors and gates. The IBC Commentary addresses this by stating that “the 54-inch (1372 mm) maximum height is intended to override the maximum 48-inch (1219 mm) reach range in ICC A117.1.”

The 2010 ADA Standards for Accessible Design (effective 03/15/2012) include an important change relative to the mounting height of hardware. In the previous edition of the ADA standard, section 4.13.9 included this statement: “Hardware required for accessible door passage shall be mounted no higher than 48 in (1220 mm) above finished floor.” The standard did not define the low-limit of the hardware mounting height, it only required a mounting location of 48” or less above the floor. This could be interpreted to mean that hardware mounted very low would be acceptable on an accessible door, even though hardware in that location may be impossible for someone using a wheelchair to operate.

The 2010 standard contains language very similar to the IBC – requiring operable hardware to be mounted between 34 inches and 48 inches AFF, and also includes the exception for swimming pools. Instead of an exception for locks used only for security purposes, the ADA attempts to more clearly define locations where existing doors may have hardware mounted outside of the 34 inch to 48 inch range: “Existing locks shall be permitted in any location at existing glazed doors without stiles, existing overhead rolling doors or grilles, and similar existing doors or grilles that are designed with locks that are activated only at the top or bottom rail.”

NFPA 101 – The Life Safety Code requires the releasing mechanism for any latch, other than existing installations, to be located between 34 inches and 48 inches AFF. When an existing security device is allowed on individual living units and guest rooms of residential occupancies, that device must be located not more than 60 inches AFF. Existing panic hardware may be mounted between 30 inches and 48 inches AFF, and the releasing mechanism for other latching hardware may be mounted below 48 inches AFF. The low-limit for existing hardware is not specifically called out in the newer editions of NFPA 101, and older editions of NFPA 101 only included a maximum mounting height of 48 inches AFF as well.

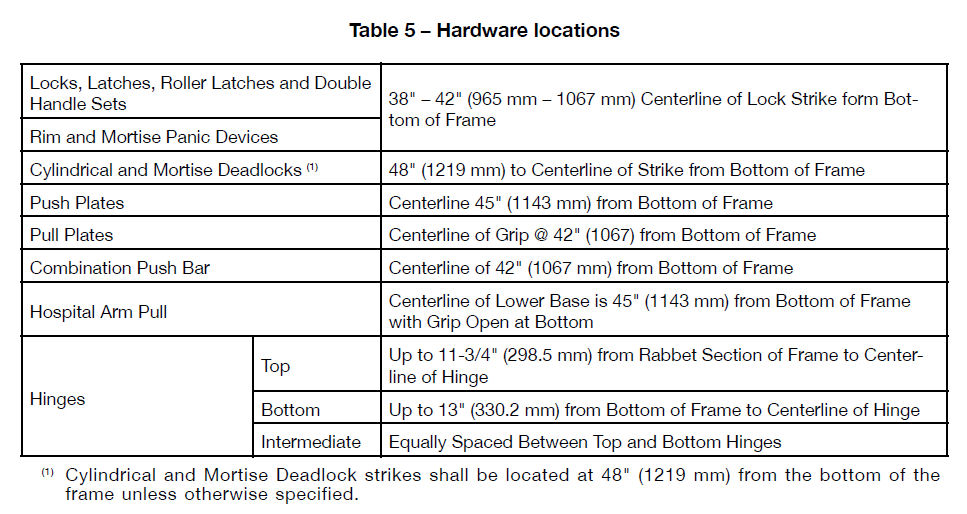

For recommended mounting locations of hardware, consult the Steel Door Institute (SDI) publication ANSI/SDI A250.8 – Recommended Specifications for Standard Steel Doors and Frames. Table 5 includes recommended locations for most products. Hardware not included in the table should be mounted per the manufacturer’s instructions.

It’s important to check your local codes for differing requirements. For example, in Massachusetts the range for accessible hardware is 36 inches to 48 inches AFF instead of 34 inches to 48 inches, and in California, operable hardware must be mounted between 34 inches and 44 inches AFF. The AHJ should be consulted for official interpretations when necessary.

You need to login or register to bookmark/favorite this content.

Hey Lori,

In your investigation, when mounting heights of pulls are discussed, is that typically the CENTER of the pull, or any operating portion? We have an installation where the storefront guy put some offset pulls above the exit device and the center of the 20″ overall pull is definitely above the 45″ (or 42″ or 48″) dimension. However, the “operating portion” of the pull is within that range of heights. If the dimension is to the pull center, then how would that apply if one desires a very long pull, say 48 inches or so? I’ve not seen anything terribly clear on this. Thanks,

Hi Nathan –

I don’t know of anything in the codes that specifically addresses this, but common sense tells me that as long as a portion of the pull is within the required mounting height range, you’re ok. That’s just my opinion – an AHJ may have a different idea. I could ask on the Building Codes Forum if you’d like. There’s a diagram in the Massachusetts Architectural Access Board standards that shows the dimension, and for pulls it looks like they’re dimensioning to the bottom of the pull. You can see the diagram here: http://idighardware.com/2009/06/bottom-rail-deadlock/

– Lori

Measuring height to a usable portion of the trim makes sense to me, too. Thanks!

Lori,

How would you interpret the requirement for a pull bar such as the Rockwood RM5510? It is tapered, so the full height of the pull would not be very accessible. The customer wants to mount it with the very top of it being 52″ AFF, which would put the center of the pull at 46″. Would that meet ADA?

Hi Todd –

Because of the shape I think they might want to mount it a little lower, but the standards are not specific enough to force it. It seems like it would be a little high aesthetically anyway.

– Lori

Lori,

We are in Texas, and are doing a Highrise Multifamily project just outside Downtown Houston. My question is, does a thumb-turn only deadbolt at the Unit Entry (leading into tenants apartment unit) need to be within the 48″ AFF range? Or does this fall into the “security hardware” category? We have completed more than (30) Multifamily projects in Texas, and we have always played it safe, and made sure this Thumb-turn only deadbolt was within the 48″ range. That said, this project is calling for an electronic deadbolt that has a large cover plate. This cover plate is pushing my thumb-turn only deadbolt into the range of 51″ AFF. Is a thumb-turn only deadbolt (these are required in Texas at Residential Unit Entry Doors) fall into the category of hardware used for “security purposes”? If so, 51″ AFF should be acceptable? Your input will be much appreciated.

So you have a better idea of the condition and its hardware. We have a cylindrical passage lever (bottom bore), Electronic Deadbolt (middle bore), thumbturn only deadbolt (top bore – bored only half way through door. only accessible from unit side of door)

Hi Mike –

In my experience, the deadbolt and the latching hardware both have to fall within the 34-48″ AFF area (34-44″ in California). All of the operable parts need to be within this range, including the reader or keypad. You may find a code official who will have a different interpretation, but most of the AHJs I’ve worked with have required all operable parts to be within the allowable range.

– Lori