I’m currently working with the BHMA Codes, Government, and Industry Affairs Committee to help edit the Commentary for the 2021 IBC. With each edition, we are bringing a little more clarity to the code sections related to doors and hardware. The side benefit of reading the entire door section again (41 pages!) is that it reminds me of the changes that I need to mention here on iDigHardware.

I’m currently working with the BHMA Codes, Government, and Industry Affairs Committee to help edit the Commentary for the 2021 IBC. With each edition, we are bringing a little more clarity to the code sections related to doors and hardware. The side benefit of reading the entire door section again (41 pages!) is that it reminds me of the changes that I need to mention here on iDigHardware.

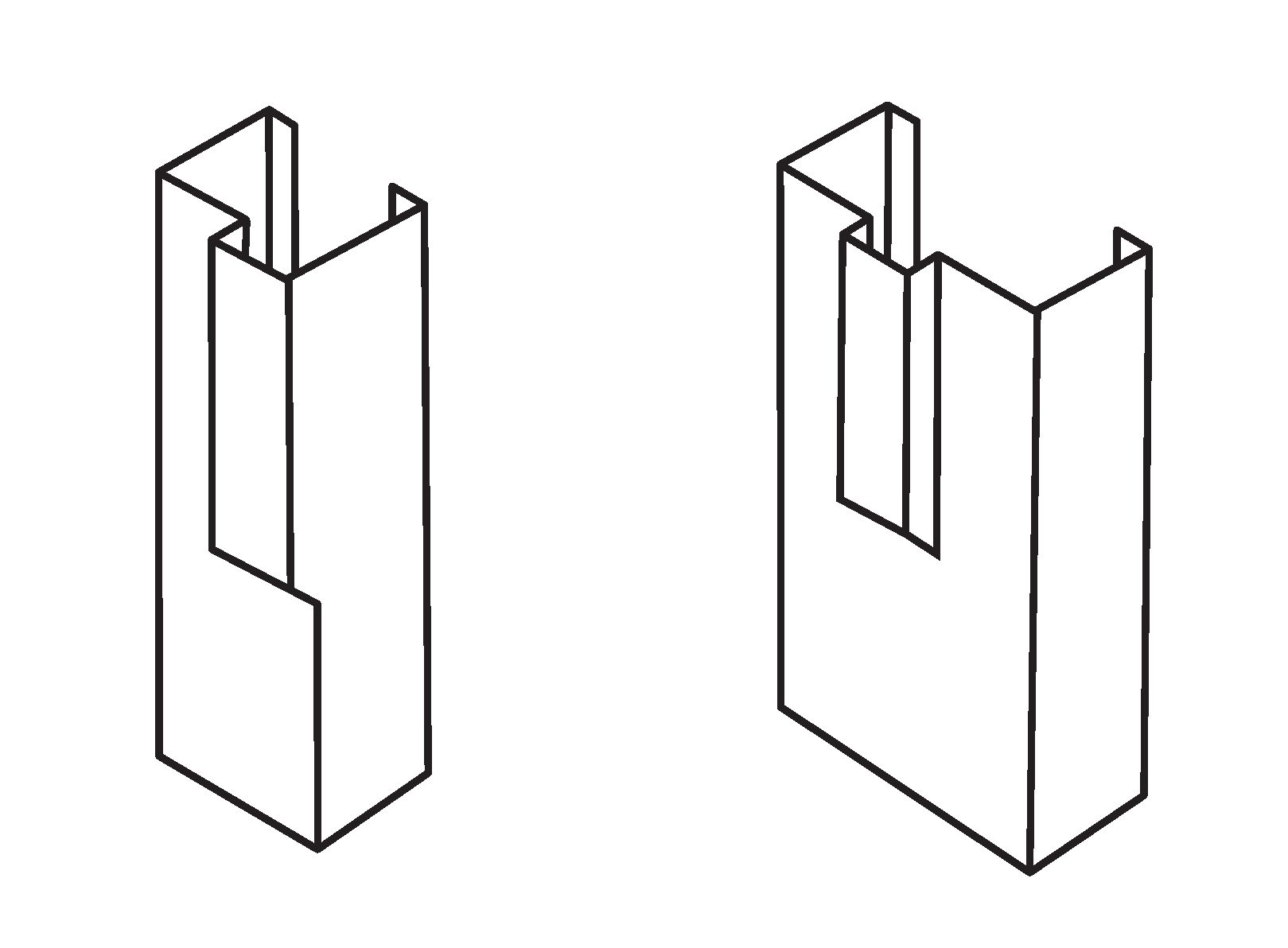

During each code development cycle, BHMA submits dozens of proposals and helps to guide them through the approval process. One of the proposals for the 2021 edition addressed terminated stops on fire door assemblies. These stops are also known as hospital stops or sanitary stops.

I wrote a Decoded article on this topic back in 2014, but at the time the IBC did not specifically state whether terminated stops were allowed on fire door assemblies. During the most recent code change cycle, BHMA’s change proposal was approved, and new language has been added to the 2021 IBC; the complete proposal begins on page 453 of the 2018 Group A Public Comment Agenda (note that the proposal was approved as submitted and was not modified by the public comments).

Although the IBC was previously silent on terminated stops, that does not mean terminated stops on fire door assemblies were not allowed by the IBC. As my earlier article demonstrated, these stops were allowed by the frame manufacturers’ listings. The change to the IBC merely clarifies where the stops are NOT allowed – they are acceptable for use in other locations.

The 2021 IBC will include a definition for terminated stops:

The 2021 IBC will include a definition for terminated stops:

TERMINATED STOPS. Factory feature of a door frame where the stops of the door frame are terminated not more than 6 inches from the bottom of the door frame. Terminated stops are also known as “hospital stops” or “sanitary stops”.

And the following clarification has been added to the code section addressing smoke and draft control doors:

716.2.2.1.1 Smoke and draft control. The air leakage rate of the door assembly shall not exceed 3.0 cubic feet per minute per square foot (0.01524 m/s × m) of door opening at 0.10 inch (24.9 Pa) of water for both the ambient temperature and elevated temperature tests. Louvers shall be prohibited. Terminated stops shall be prohibited on doors required by Section 405.4.3 to comply with Section 716.2.2.1 and prohibited on doors required by Section 3006.3 Item 3, 3007.6.3, or 3008.6.3 to comply with Section 716.2.2.1.1.

This clarification means that if there is a door that is required to comply with this section, and it is required to have limited airflow in accordance with Section 716.2.2.1.1, and the door is installed in one of the following locations, the frame can not have terminated stops (terminated stops are allowed in locations not specifically listed here):

- 405.4.3: Elevator lobby doors in underground buildings where the elevator serves more than one compartment

- 3006.3, Item 3: Elevator hoistway doors where hoistway protection is required by Section 3006.2.

- 3007.6.3: Doors to enclosed fire service access elevator lobbies, with the exception of doors to the hoistway, elevator control room, or elevator control space.

- 3008.6.3: Doors to occupant evacuation elevator lobbies, with the exception of doors to the hoistway, elevator machine rooms, machinery spaces, control rooms, and control spaces within the lobby enclosure smoke barrier.

I hope this helps to clarify this issue…we’re starting work on the 2024 editions of the model codes, so if there are any sections that you think should be changed or clarified, let me know!

You need to login or register to bookmark/favorite this content.

I find it odd that this is being addressed so narrowly to include elevator lobbies and the like, but not smoke partitions, smoke barriers, or smoke compartments. As smoke tends to rise, the lower portion of the door is rarely a concern for smoke leakage. Even when listing agencies test doors, they almost ignore much of the bottom of the door. If the smoke is going to pass through the lower 6-inches, shouldn’t we also worry about going under the door? Will required auto door bottoms be next?

Is there some science which is pushing this change, and if so, why doesn’t the science require a change to other “smoke” doors? This is one of those counter-intuitive changes to the code that ought to have a little more explanation in the code if it’s to be adopted.

Hi Rick –

The locations where terminated stops are not allowed are the same locations where doors are required to comply with the air infiltration limitations when tested in accordance with UL 1784 –

without an artificial bottom seal.

In other locations where the code limits acceptable airflow, the door can be tested to UL 1784 with an artificial bottom seal (a big piece of tape) covering the bottom 6 inches of the door and any gaps there. In those locations, the 6-inch terminated stops would have no effect on the outcome of the test, because that area is covered by the artificial bottom seal.

The code change is clarifying that doors tested WITH the artificial bottom seal can have terminated stops on the frame, and doors that have to be tested WITHOUT the artificial bottom seal can not. I hope that helps.

– Lori

I can recall conversations eons ago about these “sanitary stops”. Having observed both types in actual hospital operation, it is easier to maintain cleanliness when you don’t have to hand detail cleaning the floor areas adjacent to the stop. If they are not clean, folks cast aspersions on the whole process and facility in my experience. Most of the discussion from many years ago centered on the fire and smoke characteristics of the gap between the door and frame. I can remember the AHJ’s in that era noting that in most situations the buoyancy of the smoke kept it above the opening and that except in a heavy fuel load situation, a light hazardous occupancy like a hospital, loaded with detectors and fire sprinklers, they did not pose much problem fire wise.

Once, I personally observed a situation where this was not the case. A nurse set down a plastic tray full of medical items that were plastic in nature in a utility room and left the room. In that time, there were hot plates in utility rooms. Of course, the hot plate was fully on. The fire detector spotted the ionization and we all responded to the room. As we approached the room we saw a dense, heavy white colored smoke flowing out from under the door like fog. A most unpleasant smelling fog it was. So I believe that some burning materials could produce a problem even close to the floor. In a modern hospital, I think this is unlikely, my opinion.

I wish iDigHardware was around in those days, Jerry. Just think of the photos you could have shared! 😀

– Lori

Thanks, Lori!

Always nice to learn new things.