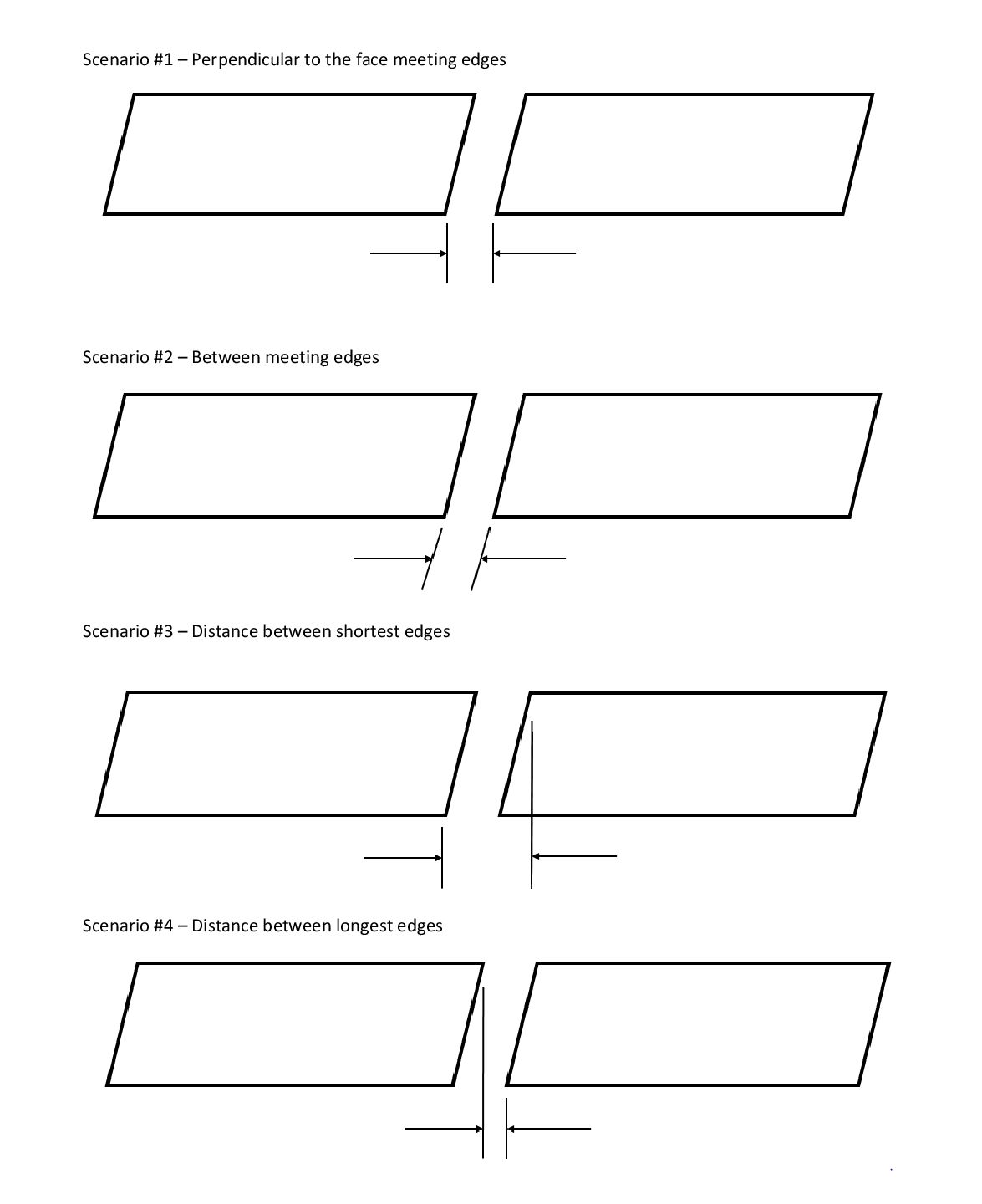

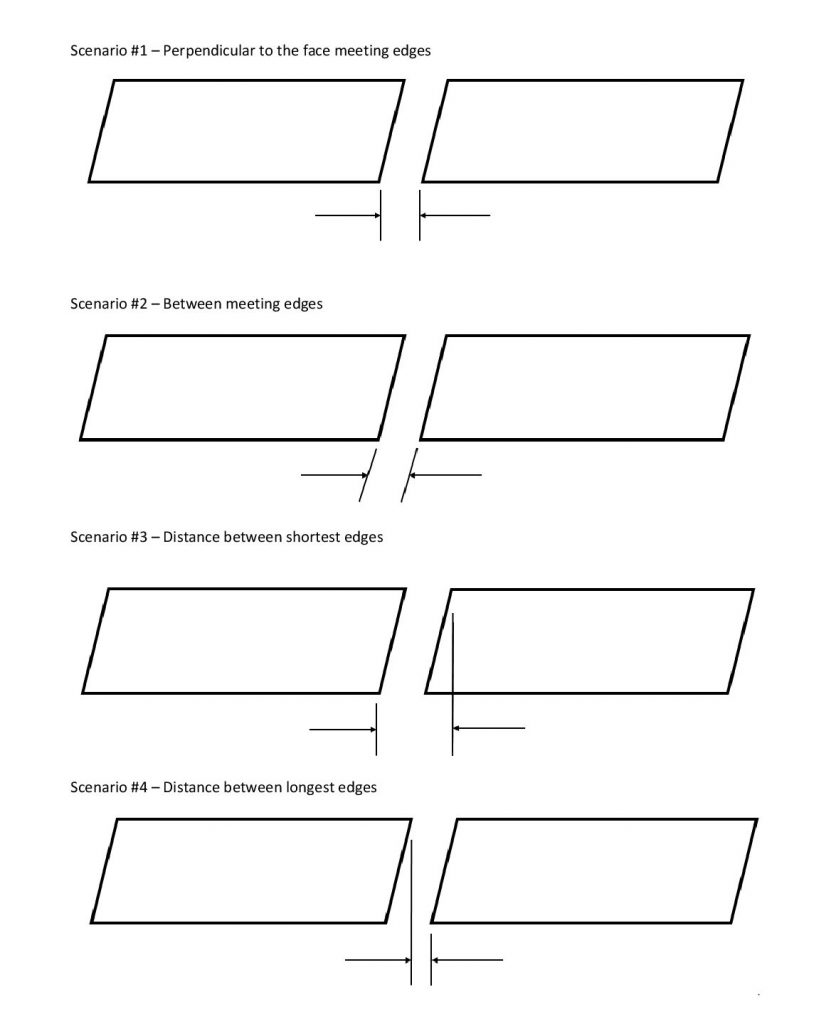

Here’s a question for all of the distributors, fire door inspectors, AHJs, CDCs, and anyone else out there who has an opinion. When you’re calculating the “prefit” door widths for a double-egress pair (and how much clearance there is at the jambs and meeting stiles), how d0 you measure the clearance at the meeting stiles? If the doors are fire doors or smoke doors, how would an AHJ / inspector measure the clearance in the field?

This is not specifically addressed in the codes or standards, so see below for the 4 options, and vote! If you have any thoughts on why the clearance would be measured in a certain way, please leave a comment to elaborate. I know this question is pretty far into the nitty-gritty, but it’s a real question that came across my desk this morning. 🙂

WWYD?

You need to login or register to bookmark/favorite this content.

i think most inspectors would measure the doors as in scenario # 1

Just a comment about prefit door sizes when ordering double egress doors to fit a hollow metal frame. Steelcraft makes the double egress frame head 1/8 inch under your order size for the head so 2 standard width beveled doors fit the frame and give the proper clearance at the meeting stiles. For instance, a 60 head is not 60 but 5′ 11 7/8″ in the net door opening head size.

That’s a very interesting point!

– Lori

Perfect point, this allows Steelcraft’s standard 13/16″ actual door finish size (on wide side) to fit their undersized head with needed or allowed gap. Wood doors should work if sized the same in theory following the math but we all know installers who have to set large double egress frames do not have an easy task, a jamb being off even the slightest or twisted when set can cause many problems when it comes time to hang doors, add partial height edge guards to the mix and the tolerances are that much tighter. Thanks Lori and Clair.

To add to Clair’s point, that’s assuming a hollow metal door (or a wood door that’s 1/4″ undersized). That’s not always the case in wood doors, as they can be made to order any size needed.

It would seem that options #1 and #2 would provide the same dimension if measured at the face. However, I would think that since the code references clearance, then option #2 would be the correct form of measurement since it truly measures clearance through the opening. The fact that the gap is not perpendicular to the face of the door is irrelevant since it is still a gap of a given width.

I can guess that many would choose option 1 as this is the simplest measurement even though it is not the true gap between the doors. I lean toward option two as that is the real gap between the doors and the width of the space allowing air flow. Definitely not options 3 or 4

I went with option #2 because I would use a gap gauge for the measurement. It seems more fool proof than holding a ruler up to it–as you would have to do in option #1. I don’t see how options #3 and #4 are relevant to measuring gaps.

#1 or #2, since they’re both the same, at least that’s what my 5th grader tells me.

#2 – because smoke doesn’t know the door faces aren’t perpendicular to the gap. Mathematically, the width of the gap is a perpendicular measurement across the gap. If smoke were a solid you were trying to prevent from penetrating the door, what is the thickness of a sheet of smoke that would fill the gap? #2 – at it seems obvious to me.

Also, Lori, think of it as if you had drawn a corridor instead of a pair of doors. How would you measure code clearance in the corridor?

I would measure straight across.

– Lori

#2 seems most reasonable, though I could see many AHJs doing #1 as it’s easier. Like Ken said, these should theoretically be the same, but in the field small dimensional and mounting differences could create a much larger gap on one side than the other.

#2

How about similar to #2, but with the doors pushed as far as they will travel against their latches (if the latches are tight, that would be less than #1, but if the latches are sloppy it could be greater.

How would overlapping metal astragals effect this?

I had the same question…it would basically be impossible to measure if there were overlapping astragals on both sides.

– Lori

I agree with Ken. Scenario #1 and #2 would be equal.

Clair is correct regarding the undersized header. Ceco does the same thing.

Somehow, there always seems to be a problem with the door hitting the stop (at header) when it closes.

Thanks for asking! Seems like some agreement so that is good. What will happen is an AHJ/or Inspector will determine #3 or #4 and ask for changes. No matter the code or requirement this happens. An AHJ who is pretty sure they know best.

As I recently reminded my fire code class, if you believe you are right, never argue; just let them know that they will need to cite a code. In California it is the law that they cannot enact any enforment unless they can cite a code. Asking for this simple step, cite the code, almost always wins the day.

George’s analogy work best. #1 would be a diagonal measurement across a corridor which would be greater than measuring perpendicular to the walls like #2. So, #2 would be the correct gap measurement but in easiest vs correct measurement, I see easiest winning out in the field. At the small scale we’re dealing with though, 1/8″ in 2″ bevel, you would need a micrometer to detect the difference. If you draw an exaggerated bevel on paper, the difference becomes quite clear.

As a member of an AHJ, I go with Bob on this. Often these days, the AHJs do not have the budget for any specialized equipment, so Option 1 is a more affordable way for an AHJ to measure. If the initial measurement seems iffy, then we ask for a more accurate measure.

Overlapping astragals would seem to moot the gap requirement as long as they were tested for the rating of the door. The problem with astragals is ensuring that the meeting door planes are parallel and the astragal is snug against the plane.

I use a wedge tool so it is kind of a mix though I picked #2 but it can be #4 if I don’t tilt the wedge.

I noticed after I commented before that the way the arrows are drawn on #2 are actually the same measurement as #1. The arrows should be drawn perpendicular to the bevel lines on #2 but I think we are all interpreting it like that anyway.

If your concern with the door clearance at the meeting point is specific to fire listing I would argue that #4 is the correct measurement method. During every UL10B/10C fire test I have overseen, the clearance between the doors for compliance to the standard is taken via #4. The “gap” between doors during the fire evaluation and after the hose stream is measure perpendicular to the face through the depth of the doors. Through openings and deflection of pair doors in the plane of the face is determined via a 90 degree viewing angle which is how #4 would measure. Double egress presents a unique issue due to the bevels being at the same angle and I could probably make a good argument for any of the methods depending on the particular code. Hence the issue Glen touched on.

The #4 drawing is a bit exaggerated but in a real situation, aren’t the high side of each bevel at the centerline of the opening making the #4 clearance essentially 0″? Curries says they back off the stops by 3/32″ from the head centerline so there’s less chance that the doors will hit them.

Fire does not travel in a straight line – the total clearance between the doors is what is called out in the code and the only thing that matters. # 1 and # 2 yield the same dimension as others have pointed out

I find it very interesting that no one (even on this small sample size) can agree on the actual way to measure this clearance. Therefore, the complications and disagreements in the field. In addition, the fact the UL10C (the benchmarks for fire rated hardware and doors) measures via #1 for pretest and #4 for test compliance to the standard adds even more confusion. Paul’s remark about fire not traveling in a straight line is absolutely correct, and yet UL10C do not consider an opening in the protective unit to be a failure unless it can be viewed at a 90 degree angle to the face of the unit (Section 14.3 UL10C). #1 and #2, geometrically, will not always yield the same dimension although the door thickness we typically deal with and the relatively small angle of bevel make this difference negligible in most cases.

#2

I agree that in a perfect world options 1 and 2 would give you the same dimension. #1 is easy to measure in the field with a tape. Either would be easy to test fit using shims of known thickness, assuming no astragals or on only one side. A sloppy fit with an 1/8″ shim would disqualify a pair of wood doors. If it’s snug or you can’t slide the 1/8″ shim between the leaves but the doors operate as intended then you are good to go. Assuming a true 72″ head, I order my wood doors at 35-7/8″ wide (assuming beveled both edges). The two wide faces actually line up, meaning scenario #4 is 0″. The door clearance comes from the parallel bevels. If the HM frame mfr under-sizes their heads at DE frames I just adjust my door width accordingly. If you have a code guy out there measuring each gap you could always oversize your wood doors by 1/32″ each. As long as the doors don’t interfere with each other upon closing, they could actually touch, though I think you’d be pushing your luck if you tried to order them that way. A 1/32″ oversize would still leave a 1/16″ gap between the doors (again, in a perfect world) and they would not interfere with each other. I say #2. We’re concerned about air-flow and if I leave a 1/8″ gap at scenario #4 then I really have a 1/4″ air gap between the doors.

Interesting puzzle for a rainy Sunday! If the measure line in #2 was perpendicular to the stile edges, that would be the best measure of the gap between the 2 parallel lines. This distance would be (very) slightly less than measuring across the face plane of the doors. Maybe an argument to use if a pair is rejected due to a 9/64″ gap measured as in #1.

Ummm … I thought from the text you were talking of the meeting of the doors and the diagrams were looking from above at door edges. If it is double egress, both doors swing the same direction and the bevel on the doors will be opposite. No? If so, the low sides of the bevels will be on the push side and the high sides on the pull side. I am not at a computer to sketch that diagram, but the gap would clearly be measured from the extent of the high sides since at rest that is the point of closest approach.

Hi Martin –

There’s a diagram showing 4 different possibilities…maybe you’re not seeing that?

– Lori

I see the diagrams but this means I do not understand what you are diagramming. I could leave it as “I am Canuck and we do things differently.” However, I will follow the discussion and see what comes up as it still sounds to me like you want the space between the pair of doors when there is no mullion.

The question was how to size a pair of double-egress doors and how an AHJ would measure the clearance between the leaves.

– Lori