A question came up yesterday about whether protection plates labeled for use on fire door assemblies could be installed with screws or if they required adhesive instead, so I did a little research. It seems like this is a potential pitfall that should be considered during the specification and detailing of a project.

A question came up yesterday about whether protection plates labeled for use on fire door assemblies could be installed with screws or if they required adhesive instead, so I did a little research. It seems like this is a potential pitfall that should be considered during the specification and detailing of a project.

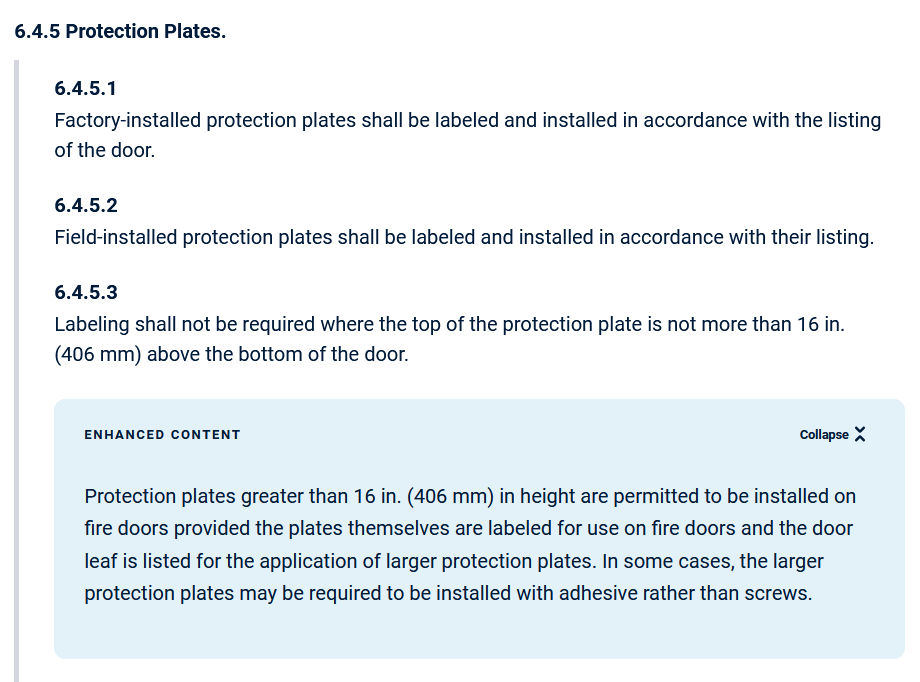

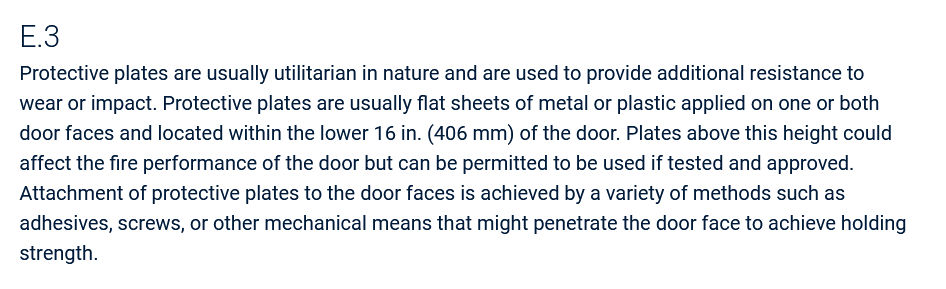

First, I checked NFPA 80 – Standard for Fire Doors and Other Opening Protectives. The text of the standard does not state a required fastening method for protection plates, but the enhanced content in NFPA Link references the possibility that larger plates may have to be installed with adhesive instead of screws (I found this same reference in a previous NFPA 80 Handbook).

There is a related but inconclusive reference in NFPA 80 Annex E – Surface Attachments to Swinging Door Faces:

Because NFPA 80 doesn’t include prescriptive requirements for the attachment of these plates, it comes down to the listings of both the fire doors and the labeled plates. There are some labeled plates that must be installed with screws – adhesive is not permitted by their listings (likely because of how they were tested). I have a Decoded article that mentions this:

All recent editions of NFPA 80 allow non-labeled plates mounted within 16 inches above the bottom of the door, but plates that are mounted or extend above the 16-inch mark are required to be labeled. Beginning with the 2016 edition, the label requirement applies to both factory-installed plates and plates that are field-installed. In both cases, the plates must be in accordance with the listings of the door manufacturer. For example, a door manufacturer’s listings may allow a plate up to 48 inches high, on one or both sides of the door. The listings may also specify the type of material that is allowed, and may require a certain type of fasteners or adhesive to be used. In some cases, the door manufacturer’s listings may allow either labeled or non-labeled plates to be installed, but in order to comply with NFPA 80, the plates must be labeled if extending above the bottom 16 inches of door height.

I checked our Steelcraft listings, and either fastening method for plates is allowed:

But then I checked a wood door manufacturer’s technical information and found that: “for ratings 20-minute through 60 minute, application may be by fastener or adhesive. For ratings of 90-minute, application shall be by adhesive only.”

As a former specwriter, I can see a potential for problems if a plate that is required by the listings to be installed with screws is specified for a fire door that requires installation with adhesive. So my question for you is this:

Is this an issue that arises in the field due to lack of coordination, or is it just overlooked? WWYD?

You need to login or register to bookmark/favorite this content.

All fastening method must be mentioned in the hardware set, period.

I don’t disagree, but I could see this being missed – especially if there are several manufacturers listed in the spec, and there is a combination of plate + door that doesn’t match up.

– Lori

It would be interesting to know how screws vs. adhesive hold up in tests. The testing agencies must know, I’m hoping someone can share their insight.

Hi Glenn –

I’m not positive but I’m guessing plates with adhesive eventually fall off during the test.

– Lori

As a long time installer……..I was on a Hotel job this past summer, and on the Hardware Schedule was noted that 10″ high kick plates were changed to 8″ high per fire code. Was this a “local Code” thing?? I would think that any kick plate or armor plate added to a Wood Fire Door (gyp core) would be a added protection to the the door face .

The only time I’ve used double face tape was on X-ray (lead lined) doors.

Hi Bob –

I don’t know of a code-related reason why a 10-inch kick plate would be changed to 8 inches. That is not the type of thing that would usually be different in the local codes. The main difference in NFPA 80 is that if the plate is installed in the bottom 16 inches of the fire door, the plate does not have to be labeled. If it’s a taller plate or something like a stretcher plate that is mounted above the 16-inch point, the plate has to be labeled, which can affect the attachment method.

– Lori

Bob – local code is permitted to be more restrictive than International Code – NEVER less. So it doesn’t surprise me that your local AHJ / Fire Marshall required them to be shorter than it even was! You would think it would be added protection, but they proved in testing anything higher than 16 inches may possibly distort the door or create other reactions during a fire.