As I’m reviewing and updating these Decoded articles, I can’t believe that some of them were originally written more than 12 years ago. Hopefully they will continue to be a valuable resource for another 12 years and beyond!

This post was published in Doors & Hardware

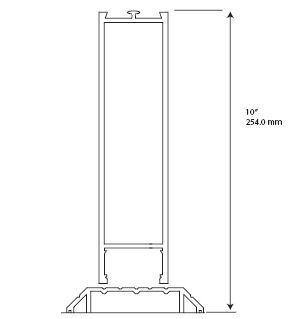

The 2010 ADA Standards for Accessible Design (available for download at www.ada.gov) went into effect on March 15, 2012, and continue to be the edition of the standards that help to ensure compliance with the Americans With Disabilities Act (ADA). This edition of the ADA standards includes a requirement for manually-operated doors to have a flush, smooth surface on the push side, measuring at least 10 inches up from the floor. This was not mandated by previous editions of the ADA standards but was a requirement of ICC A117.1, Accessible and Usable Buildings and Facilities. ICC A117.1 is the accessibility standard that is referenced by the International Building Code (IBC).

The 2010 ADA Standards for Accessible Design (available for download at www.ada.gov) went into effect on March 15, 2012, and continue to be the edition of the standards that help to ensure compliance with the Americans With Disabilities Act (ADA). This edition of the ADA standards includes a requirement for manually-operated doors to have a flush, smooth surface on the push side, measuring at least 10 inches up from the floor. This was not mandated by previous editions of the ADA standards but was a requirement of ICC A117.1, Accessible and Usable Buildings and Facilities. ICC A117.1 is the accessibility standard that is referenced by the International Building Code (IBC).

The text of both standards is very similar, although not exactly the same. For reference, here is the applicable section from the ADA standards:

404.2.10 Door and Gate Surfaces. Swinging door and gate surfaces within 10 inches (255 mm) of the finish floor or ground measured vertically shall have a smooth surface on the push side extending the full width of the door or gate. Parts creating horizontal or vertical joints in these surfaces shall be within 1/16 inch (1.6 mm) of the same plane as the other. Cavities created by added kick plates shall be capped.

EXCEPTIONS:

1. Sliding doors shall not be required to comply with 404.2.10.

2. Tempered glass doors without stiles and having a bottom rail or shoe with the top leading edge tapered at 60 degrees minimum from the horizontal shall not be required to meet the 10 inch (255 mm) bottom smooth surface height requirement.

3. Doors and gates that do not extend to within 10 inches (255 mm) of the finish floor or ground shall not be required to comply with 404.2.10.

4. Existing doors and gates without smooth surfaces within 10 inches (255 mm) of the finish floor or ground shall not be required to provide smooth surfaces complying with 404.2.10 provided that if added kick plates are installed, cavities created by such kick plates are capped.

This requirement appears in the “Manual Doors” section of both publications, so it does not apply to automatic doors. The purpose is to avoid creating a projection that could catch a cane, crutch, walker, or wheelchair and inhibit passage through the door opening, so the requirement applies to the push side of the door only. The 10-inch measurement is taken from the floor or ground to the top of the horizontal bottom rail, extending the full width of the door. Prior to the 2003 edition of A117.1, the required dimension was 12 inches, vs. the 10 inches required by today’s standards.

The 10-inch-high area must have a smooth surface, so there are some types of hardware that are in conflict with this requirement and should not be used on manually-operated doors that are part of an accessible route. This includes the bottom rods and latches of surface-mounted vertical rod panic hardware, kick-down stops and plunger holders, surface bolts, automatic door bottoms, and full-height door pulls that extend into this area of the door on the push side.

The 10-inch-high area must have a smooth surface, so there are some types of hardware that are in conflict with this requirement and should not be used on manually-operated doors that are part of an accessible route. This includes the bottom rods and latches of surface-mounted vertical rod panic hardware, kick-down stops and plunger holders, surface bolts, automatic door bottoms, and full-height door pulls that extend into this area of the door on the push side.

This requirement also affects the door’s bottom rail, the top of which must be at least 10 inches above the floor. If kick plates are added to increase the height of the bottom rail, the space between the top of the kick plate and the glass must be capped, and the joints between surfaces are limited to a 1/16-inch variation in plane. The 2017 edition of ICC A117.1 clarifies that a kick plate applied for the purpose of increasing an existing bottom rail must extend to 10 inches above the floor and to within 1 inch of the sides and bottom of the door.

Sliding doors and doors that do not extend to within 10 inches of the floor are exempt from the flush bottom rail requirement. Tempered glass doors with no vertical stiles and a tapered bottom rail do not have to meet the requirement for a 10-inch bottom rail, although they are still subject to the prohibition on hardware projections. I am often asked about patch fittings for bottom pivots on glass doors. Because they are not continuous across the bottom of the door, and the difference between the plane of the glass and the face of the patch fittings would likely be more than 1/16-inch, I think most AHJs would find patch fittings non-compliant.

Since the standards have become consistent, there has been an increase in awareness and enforcement of this requirement. And if the wider bottom rail results in a wider top rail and vertical stiles, you won’t hear me complaining!

You need to login or register to bookmark/favorite this content.

Storefront installers always want to install sweeps on the push side of the door. When I confront them about it they say it is how they are told to install them. They do not like it when I bring up this code and let them know that the sweep they have installed sticks out more than allowed and that it need to be installed on the pull side of the door where it will actually do some good.

That makes sense – both code-wise and functionally!

– Lori

Very good point that I have forgotten about on some applications with automatic door bottoms!!!! You cannot use surface mount ones in this application!

What about a door that has an undercut of 2” or more, would this comply in your opinion since the code does not specify what height the bottom of the door needs to be?

That’s an interesting question, Phil. I think a large undercut would be acceptable (as long as the door is not fire-rated), because the standard measures the 10 inches up from the floor.

– Lori

To meet the code requirement can you substitute the tempered glass with laminated? Or is the language specifically for laminated only?

Hi David –

I think they used the term “tempered glass doors” to mean a glass door without vertical stiles – some people use the term “all-glass door”.

– Lori