My latest Decoded article addresses upcoming changes to the 2024 I-Codes, in addition to the changes affecting electrified hardware that I covered in a previous article. You can find the article on the electrified hardware changes here.

This Decoded article was published in the January/February 2023 issue of Door Security + Safety

.

The model codes and referenced standards adopted in most U.S. states are typically revised on a three-year cycle, and the 2024 editions of the model building codes and fire codes are nearing completion. For the International Building Code (IBC), many changes have already been approved that will affect doors and hardware. The Builders Hardware Manufacturer’s Association (BHMA) Codes, Government, & Industry Affairs (CGIA) Committee has been involved in the code development process for more than 20 years, allowing us to proactively impact the code requirements related to door openings.

A previous Decoded article addressed upcoming changes to the IBC that were related to electrified hardware, including:

- Clarifications on the code requirements for “normal locking arrangements”

- The addition of UL 1034 as an alternative to the UL 294 listing

- A limitation on the use of electromagnetic locks on doors required to have panic hardware

- Additional emergency release methods mandated for stairwell reentry

- A new code section related to electrified locking of elevator lobby doors

Along with these important changes affecting electrified hardware and access control, additional changes and clarifications have been approved with regard to mechanical hardware, door size, and automatic operators. Generally, changes to the IBC also apply to the International Fire Code (IFC). Clarifications to the code will be helpful immediately, even prior to adoption of the new code in a project’s jurisdiction, and five changes related to doors and hardware are summarized in this article.

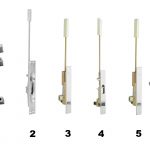

Flush Bolts – Manual, Automatic, and Constant-Latching

The 2024 IBC will include definitions for the types of flush bolts that are addressed by a new table in the code, reducing the confusion caused by the Bolt Locks section in past editions.

ICC Proposal E43-21 – Approved as Modified by Public Comment 1

The section of the IBC called “Bolt Locks” has often been misinterpreted as being applicable to deadbolts. Upon further investigation into the requirements of the section, and by reading the IBC Commentary, it is clear that the section is intended to apply to flush bolts and surface bolts installed on the inactive leaf of a pair of doors. This needed to be clarified to facilitate more consistent interpretations in the field.

There were some other issues with this section as well. For example, paragraphs three and four described locations where manual flush bolts were allowed, based on occupancy type, occupant load, and presence or absence of a sprinkler system. However, the code did not distinguish between fire doors and non-fire-rated doors in these paragraphs. Because of the positive-latching requirements, a fire door assembly would not typically be permitted to have manual flush bolts, even if it met the criteria stated in the code.

The other complication was a lack of familiarity with the various types of flush bolts – manual bolts, automatic flush bolts, and constant latching bolts (as well as deadbolts). These terms will be defined in the 2024 IBC, to differentiate between the types of bolts and the requirements that apply to each. In addition, a table has been added to clarify where each type of bolt is allowed based on occupancy type and calculated occupant load, and whether the assembly is required to be fire rated.

The 2024 edition of the IBC will include a change to clarify the intent of the requirements for a double cylinder deadbolt used on the main entrance of a building or tenant space.

Key-Operated Locks for Main Entrances

ICC Proposal E45-21 – Approved as Modified by Public Comment 1

A change to the 2015 I-Codes resulted in some confusion regarding key-operated locks. The model codes allow these locks – for example, double-cylinder deadbolts – to be installed on certain doors in a means of egress, if the criteria listed in the codes are met. Because the locks require a key to unlock them, they must remain unlocked when the building is occupied to facilitate free egress. The model codes limit the occupancy types where these locks are allowed, require signage stating that the door must be unlocked when the building or space is occupied, and mandate a lock that is readily distinguishable as locked (this is typically interpreted to mean that an indicator is required).

Prior to the 2015 edition of the IBC, key-operated locks were allowed on a building’s main exterior door or doors, in the following occupancy types: assembly (with an occupant load of 300 people or less), business, factory and industrial, mercantile, or storage, and in places of religious worship (no stated occupant load limit). In the 2015 edition of the code, the word “exterior” was removed, and a slight change was made to the required wording of the signage. The intent of the change was to allow this application to be used on the entrance to a tenant space, like a retail stair in a mall.

When the reference to exterior doors was removed, it became unclear where double-cylinder deadbolts were allowed. For example, if an end user wanted to install a double cylinder deadbolt on a locker room, with signage and an indicator, and the occupancy type and load were within the limitations of the code, it was extremely difficult to demonstrate why that did not meet the intent of the IBC.

The change to the 2024 IBC is simple, but an important clarification to show where these locks are intended to be allowed: The doors are the main exterior doors to the building, or the doors are the main doors to the tenant space. Based on this revision, double-cylinder deadbolts could be installed on the main exterior doors, or the main doors leading to tenant spaces, but could not be used on doors to individual rooms or other areas. In addition, the other criteria listed in the code must be met.

Double Egress Pairs in Health Care Smoke Barriers

Double-egress pairs installed in smoke barriers in health care facilities are not typically required to be labeled fire doors or to have positive-latching hardware.

ICC Proposal FS48-21 – Approved as Modified

One section of the IBC that has caused a lot of confusion over several editions of the code is the section addressing double-egress pairs of doors in health care smoke barriers. At one time, the common interpretation was that these doors were required to be fire door assemblies but did not require positive-latching hardware. Because fire doors are required to latch, many of these cross-corridor pairs were equipped with construction labels, stating that the doors were constructed to the same standards as labeled fire doors, but could not be labeled because they were not equipped with latching hardware. In some cases, latching hardware was installed to avoid problems with code interpretations in the field.

Over several editions of the IBC, the intent of the code became clear. Labeled fire doors are not required for double egress pairs of doors in smoke barriers in health care facilities. The applicable section of the code includes some other criteria, such as limitations on clearances, the allowable type of hold-open devices (if applicable), requirements that apply to vision panels, and the condition at the meeting stiles. But the 2021 IBC clearly states: In Group I-1, Condition 2, Group I-2 and ambulatory care facilities, where a pair of opposite-swinging doors are installed across a corridor in accordance with Section 709.5.1, the doors shall not be required to be protected in accordance with Section 716.

The referenced section – Section 716 in the 2021 edition – includes the requirements for opening protectives / fire doors, so these double egress pairs in health care smoke barriers are not required to be fire door assemblies. However, there was a line of text left in the 2021 and prior editions that continued to cause confusion: Where permitted by the door manufacturer’s listing, positive-latching devices are not required. Because the doors are not required to be labeled or listed, there are no manufacturers’ listings that could permit the omission of positive-latching devices. In the 2024 edition, this line of text will be removed.

The 2021 IBC introduced requirements for accessible public entrances serving some types of buildings to have automatic operators. These requirements will be clarified in the 2024 edition.

Automatic Operators at Accessible Public Entrances

ICC Proposals E116-21 and E119-21 – Approved as Modified, E118-21 – Approved as Submitted

One of the important changes made in the 2021 IBC added requirements for automatic operators to be installed on the accessible public entrances in certain types of buildings, depending on the use group and the calculated occupant load. In the 2024 edition, some clarifications will be made to this section. The reference to “automatic doors” will be changed to “power-operated doors”, to be consistent with other references in the code. Another change clarifies that when these entrances contain doors in a series – for example, exterior doors and vestibule doors – at least one of each must have an automatic operator.

Clarifications will also be made to the 2024 edition of the IBC to help determine which buildings are required to have power-operated doors for the accessible public entrances. Where a tenant space in one of the applicable use groups has its own exterior public entrance, it will be considered a separate facility and building for the purpose of determining power-operated door requirements. For mixed-use facilities, the code has been clarified regarding how the requirement for automatic doors is applied.

Locks for Multi-Stall Restrooms

A code change was needed in order to allow this deadbolt function to be used on multi-stall restrooms. A key can be used to throw or retract the bolt from the inside, and the thumbturn can be used to retract the bolt for egress.

ICC Proposal P35-21 – Approved as Modified by Public Comment 1

Although most of the BHMA committee’s time is spent on the model codes and referenced standards that commonly affect door openings, occasionally a change to another code or standard is needed. This was the case with the final change discussed in this article.

The International Plumbing Code (IPC) includes a section addressing the type of locks that are allowed on doors serving multi-stall restrooms. The IPC does not permit these doors to have locks that are lockable from inside of the restroom – for example, a lockset with a thumbturn or push button would not be allowed on the restroom’s main entrance door. (Note: Family and assisted-use toilet rooms are exempt from this limitation.)

In recent years many facility managers have expressed a need for multi-stall restrooms to be lockable from within the room. In some buildings the restrooms may be used as a safe haven during an active-shooter event, and an authorized person – like a teacher – would need to be able to lock the door from the inside. Another possibility is where someone cleaning a restroom needs to temporarily restrict access to the room while they are working.

Along with the ability for an authorized person to lock the door to prevent access, it is important to ensure that the egress requirements are met. There is a deadbolt function available that includes key cylinders on the inside and outside of the door, along with a thumbturn on the inside. The thumbturn can be used to retract the deadbolt for egress but will not project the deadbolt. Past editions of the IPC would not allow this function to be used on a multi-stall restroom, but an exception has been approved for the 2024 edition of the IPC that will allow access to be limited while also providing for free egress.

The new exception states that the door serving a multiple occupant toilet room may be lockable from inside of the room by an authorized person using a key or other approved means, as long as the door is readily openable from the egress side with not more than one releasing motion and without the use of a key or special knowledge or effort. The door must also be able to be unlocked from outside of the room with a key or other approved means. To comply with accessibility and egress requirements, the thumbturn must be operable without tight grasping, pinching, or twisting of the wrist. Operable parts of the lock must be mounted between 34 inches and 48 inches above the floor (or as required by state or local codes and standards).

Remember, additional changes affecting electrified hardware were addressed in a previous Decoded article; these revisions should help with more consistent interpretations. Although some changes do not apply until the new edition of the code is adopted in a particular jurisdiction, many are clarifications that can be used immediately to help demonstrate the intent of the code. Editions of the code that have not yet been adopted may be used when requesting a code modification. Be sure to check the adopted codes in a project’s jurisdiction, as they may include state and local modifications that differ from the model codes. The Authority Having Jurisdiction (AHJ) will make the final determination regarding code compliance.

You need to login or register to bookmark/favorite this content.

Hi Lori,

Does single-egress pairs of doors in health care facilities require latching hardware if they are in a smoke barrier, if so, can you reference the code.

I’ve not heard of a ‘constant latching flush bolt’ before, so I have a couple of questions about it:

1) Looking at the catalogue cuts for the IVES ‘constant’ models, why would the top-bolt have a switch on the edge of the door-panel when you have to manually unlatch the bolt anyways? What does that switch do?

2) When would you need to use a set of these instead of an ‘automatic flush bolt’?

[…] be met to install these locks. The section that applies to key-operated locks will be amended in the 2024 model codes to clarify the extent of the requirements. While the amendment clarifies that key-operated locks are […]