Sometimes when I receive a Quick Question, I have to ‘phone a friend’ for help. That was the case with today’s question:

Sometimes when I receive a Quick Question, I have to ‘phone a friend’ for help. That was the case with today’s question:

In our facility there is a mechanical room where we need a removable transom panel in a fire door assembly, to allow for the occasional replacement of mechanical equipment that won’t fit through a 7-foot door. Is this possible?

When the model codes and/or referenced standards include requirements that specifically address a topic like this, I can usually find the answer. But sometimes the answer is not in the codes or standards, and depends on what is allowed by the manufacturer’s listings. For all things hollow metal I call on Marilyn Latham, our senior engineer for Steelcraft and Republic.

Because in this particular case the full height of the door opening is needed very infrequently, a removable transom panel is the most efficient way to handle the situation. I thought maybe a swinging transom panel could be an option (kind of like a dutch door but with the bottom leaf being a standard height door), but this application is not allowed by our listings. Dutch doors are limited by our listings to 4 feet wide x 7 feet 2 inches high, and for the mechanical room in question, more opening height was needed.

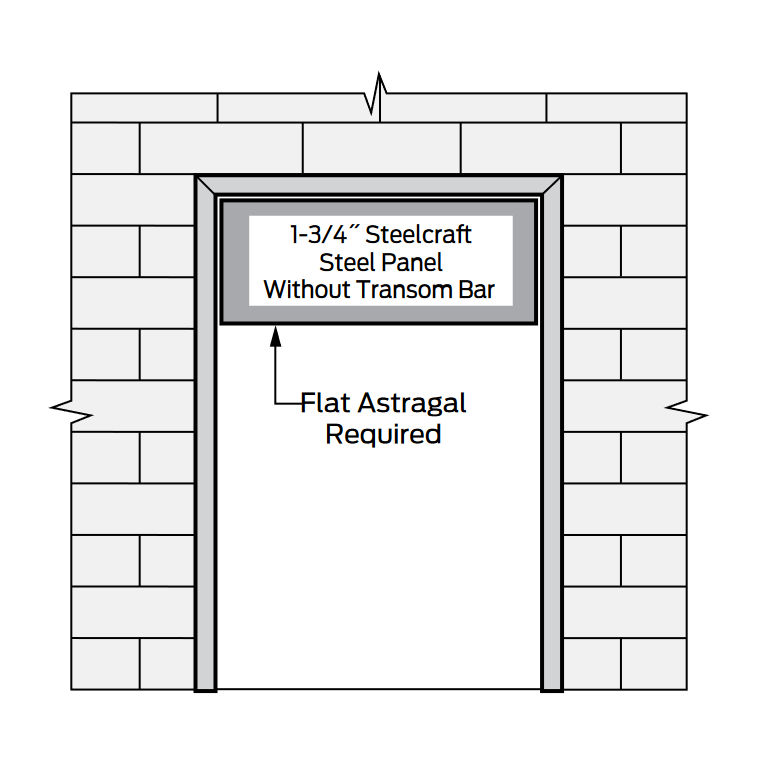

Marilyn advised that a fire door assembly with transom panel and without a transom bar could be constructed in a way that the panel could be temporarily removed and reinstalled after the mechanical equipment was replaced. The detailed information about this application is found on pages 303 and 304 of the Steelcraft Tech Data Manual. The maximum height for a hollow metal panel in this fire door assembly configuration is 48 inches, and an overlapping astragal is required at the bottom of the panel. The maximum fire rating for this assembly is 3 hours for masonry walls, and 90 minutes for stud walls. Refer to the Steelcraft Tech Data Manual for additional information.

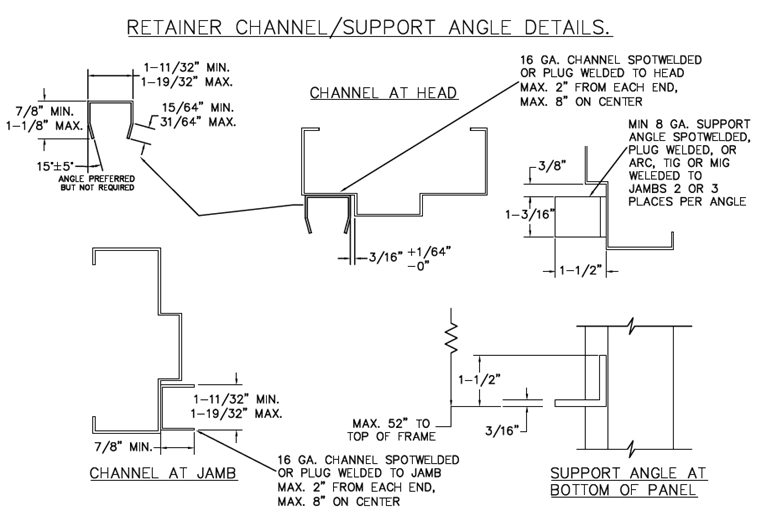

And for those of you who like to study the nuts and bolts, the installation of the panel is detailed below. 🙂

You need to login or register to bookmark/favorite this content.

Interesting

Learn something new all the time.

Have not seen it, did not think it was possible.

This is a great post – smart idea to make it work (and get the stamped rating).

Since the advent of air conditioning, I see no reason for a transom panel. Why not put a 9′ door in a 9′ frame?

Great to know such product/solution! Thanks for sharing/teaching!

Great article! It’s interesting to learn about the requirements for fire door assemblies with transom panels. I’m curious, what are some common mistakes or oversights that architects or contractors make when designing or installing these assemblies, and how can they be avoided?

Thanks

Jim from https://www.sydneyaluminiumwindows.com.au

Great question, Jim. Maybe some readers will weigh in, although this is an older post.

– Lori