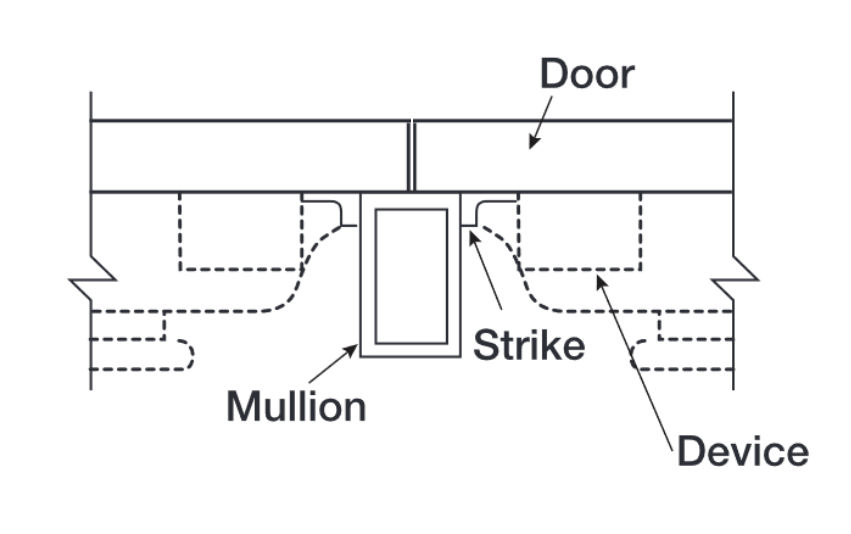

A hardware removable mullion sits behind the meeting stiles of a pair of doors, allowing rim panic hardware to latch into the mullion.

There are two primary types of removable mullions used in door openings – one that is considered a piece of hardware, and one that is part of the frame. The more common removable mullion (the hardware type) sits behind the meeting stiles of a pair of doors, and allows two rim panic devices to latch into it.

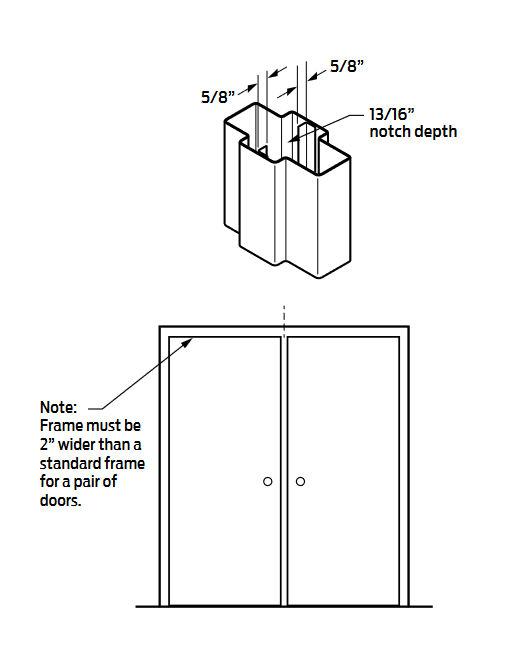

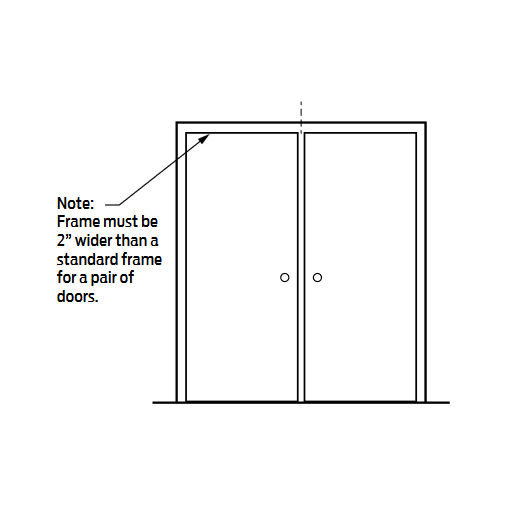

Less common is a mullion made from hollow metal frame material, with brackets that allow it to be removed when the entire width of the door opening is needed. This type of mullion sits between the doors, rather than behind them.

Hardware removable mullions are popular because they allow rim panic hardware to be used on pairs of doors, rather than vertical rod panic hardware. Panic hardware that incorporates vertical rods or vertical cables can be more challenging to keep adjusted properly, and the tolerances at the sill need to be fairly tight, so doors with this hardware require periodic attention. The rim x rim x removable mullion application is typically easier to maintain, and the panic hardware may latch more reliably.

Pairs of doors with locksets and flush bolts can result in some of the same challenges seen with vertical rod panic hardware, so my question is this…would a hollow metal removable mullion be a good application for pairs of doors where the inactive leaf is rarely used?

A hollow metal removable mullion sits between the doors, allowing each door to have a lockset or latchset.

For example, on mechanical rooms, the inactive leaf may only be needed when new equipment is moved through the opening. In health care facilities, corridor doors – including the inactive leaf of a pair – require positive latching hardware; this means automatic/constant-latching flush bolts and sometimes a coordinator. This question actually came to me from a health care facility trying to overcome problems with flush bolts.

Would a pair of doors with a hollow metal removable mullion and locksets on both door leaves be more reliable and require less maintenance than the alternative?

Other than the extra 2 inches of door opening width needed, what are the challenges with this application?

WWYD?

You need to login or register to bookmark/favorite this content.

Carts. Carts. Carts. the three main reasons knob sets and levers fail.Install one piece of panic hardware and automatic flush bolts. This is one less piece of hardware to maintain especially in a hospital setting where laundry service will use and abuse the the opening. Even C/R extra heavy duty will not survive with constant cart abuse!

As an architect, I appreciate the simplicity of a removeable mullion with rim exit devices.

However, as a high school band dad that helps move marimbas, drum sets, and equipment through a pair of doors with a non-removeable mullion or a removeable one that no one has a key for, I prefer no mullions at all. Mullions just get in the way when you most need them to be out of the way.

I too was a band dad and understand the mullion situation when moving musical instruments. Keyed removable mullions are the best but most schools do not have them. It’s always a struggle. My kid is graduated and done with band so I’m thankful I won’t have to deal with those mullions anymore

Ah yes, the conflict between ease of use and sound transmission.

A mullion really helps cut down on sound coming from the band & music rooms in schools. That gap between the doors is a sound sieve, so the mullion is a great compromise. However, as you state, it doesn’t make it easy for the users when moving large items out of that room.

We need the two doors for moving large items, but we want the mullion for “simpler” hardware and noise reduction. Perhaps a non-keyed removable mullion is better? Everyone has a hex key on them, right?

I could see where a screw-attached removable mullion would work — you’d open both doors, then unscrew the mullion from the egress side, then do your business, then reverse the process to button the opening back up then.

Mullions integrated into the door frame are my go-to choice for security and long term maintenance. It also looks more integrated into the opening; whereas movable mullions always look like an afterthought and are generally disliked universally by architects. Some folks like movable mullions because they can be removed for loading and unloading; but you often see every door in the place using MMs. How many places do you need to bring in oversized stuff?? One? maybe two? Retrofit is another reason to use MMs. If you cannot do that, then Surface VRs are my next choice. But if concealed VRs are to be used i would suggest blowing up the building and starting over (although I have had some success with your cable device). I am very interested in what others have to say about this.

Great answer, Jim .I agree hate the thought of anything concealed. After 47 years as a locksmith and Security Hardware Consultant. I have seen so many failures ,in CVR and SVR devices from user abuse and misuse

The coordinator with auto-flushbolts model requires and an almost perfect door / frame assembly and installation in order to operate smoothly and consistently. Vertical rods are also a challenge to maintain in good working order, especially when they are struck by heavy cart traffic. CVR Concealed vertical rod are not as susceptible to damage but they can be more tedious to adjust.

The objective of the two single doors with removable mullion idea is to simplify the operation and durability of opens that do NOT require double door width traffic everyday. Switchgear, boiler rooms, etc may not require wide openings 24/7. On these openings, the simpler mechanism would require less maintenance for self-closing and self-latching. The removable mullion process would need to be easy to remove and put back though.

I can see where this is coming from, fire door assemblies use automatic flush bolts and coordinators, both of which require as much or more maintenance as vertical rod devices. In cases where the center frame is removed less than once per year this request seems reasonable. The biggest issue I have found is corrosion at the bottom bracket of the removable frame section causing other maintenance headaches.

That’s a good point.

I wonder if it would make sense to fabricate the bottom bracket from stainless steel.

I also wonder if Allegion or other manufacturers can make a hardware or keyed removable mullion version of the hollow metal double ASA strike mullion that mounts between the doors for non-exit device openings.

My standard is 2 rim by key removable. Unless it is a loading dock door where things like a palette jack might be used.

I get lots of fights over this. They say we have to have the full width all the time till I point out most carts are less than 36 and if not how do you get them inside of a single door room.

I have had them fight over the look yet you cant see them from outside.

I am not sure this would work in a hospital with beds being wider.

On doors I really cant use mullion I go with surface LBR by Mortice with open back strike so I don’t have to deal with concealed or automatic flushbolts.

Lori Thanks for addressing this issue .

Do we like door pairs with manual flush bolts? Automatic flush bolts? astragals with door coordinators?

Who makes a latch position sensor for flush bolts???

Hmmm…I’ve never thought about a latch monitor for a flush bolt. For various reasons, I don’t like flush bolts – manual or automatic, or coordinators.

– Lori

Can you please elaborate a little on your issues with flush bolts? I do not like automatic FB’s but Self Latching FB’s are ok IMO. I don’t like coordinators either, though I have had really good success with the ABH 3780 version. Usually I would go with manual FB on mechanical room doors and removable hardware mullion with panics on others or self latching FB with astragal and coordinator. One thing to remember is that most people don’t have early as much understanding about door hardware operation as we do. It needs to be easy to lock/latch etc. IMO for the little bit of extra maintenance required for flush bolts this outweighs the other options. Also, make sure that the closers are adjusted so that the active door closes faster than the inactive door. This reduces wear on the coordinator.

Hi Wes –

I have just seen a lot of problems with coordinators and automatic flush bolts not working correctly, so the door doesn’t close and latch – affecting security and fire protection. Constant-latching flush bolts are more reliable, but another issue is that with flush bolts designed for wood doors, so much of the corner of the door is removed that the doors can end up cracking. I don’t mind mechanical flush bolts too much, but in health care facilities the corridor doors have to be self-latching – including the inactive leaf. This means that corridor doors in health care facilities can not have manual flush bolts.

– Lori

Fully agree with Automatic FB’s as opposed to Self-Latching FB. It is nearly impossible to overcome the pressures of the coordinator and AFB actuators but still maintain the 5 # for ADA. I also agree on the issue for wood doors if using the wood door FB. We use the “Metal door” type for all of our wood doors with much better success. Certain wood door MFG’s are able to do this prep even on a fire rated wood door. (this may be MFG SLFB specific, since some of them come with an additional guide bracket that recesses into the door) Also, I should clarify, I prefer a removable mullion with 2 rim devices over any of the other options if the budget and other factors support it.