Until the 2021 edition of the International Building Code (IBC), automatic operators were not mandated by the model codes in any particular locations. However, automatic operators are often installed when a door opening can not meet the accessibility requirements that apply to manual doors. For example:

Until the 2021 edition of the International Building Code (IBC), automatic operators were not mandated by the model codes in any particular locations. However, automatic operators are often installed when a door opening can not meet the accessibility requirements that apply to manual doors. For example:

- The door does not have the required maneuvering clearance or is recessed in an alcove

- The door can not be opened manually within the opening force limitations (5 pounds, maximum, for interior, non-fire-rated doors)

- Two doors in a series do not have the required turning space between them

- The door has a narrow bottom rail or protruding hardware in the area measured 10 inches up from the floor on the push side

In addition to addressing the requirements of the codes and standards, automatic operators are frequently installed for convenience or to facilitate “touchless” operation of the door to help control the spread of germs.

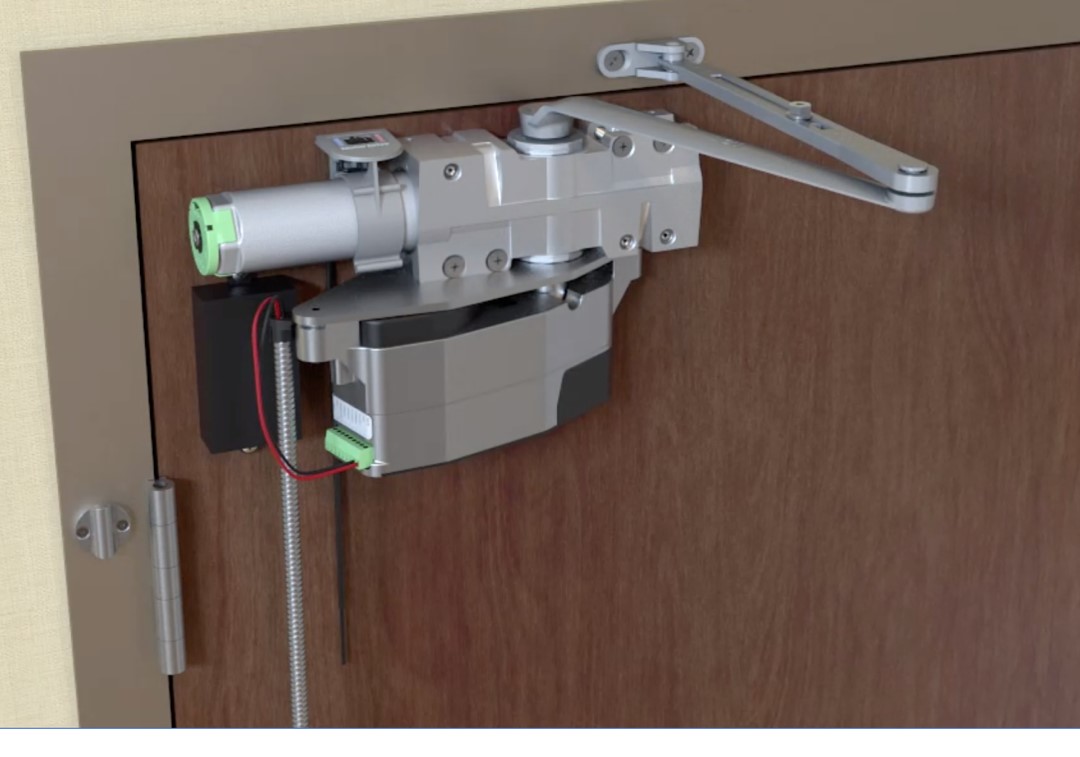

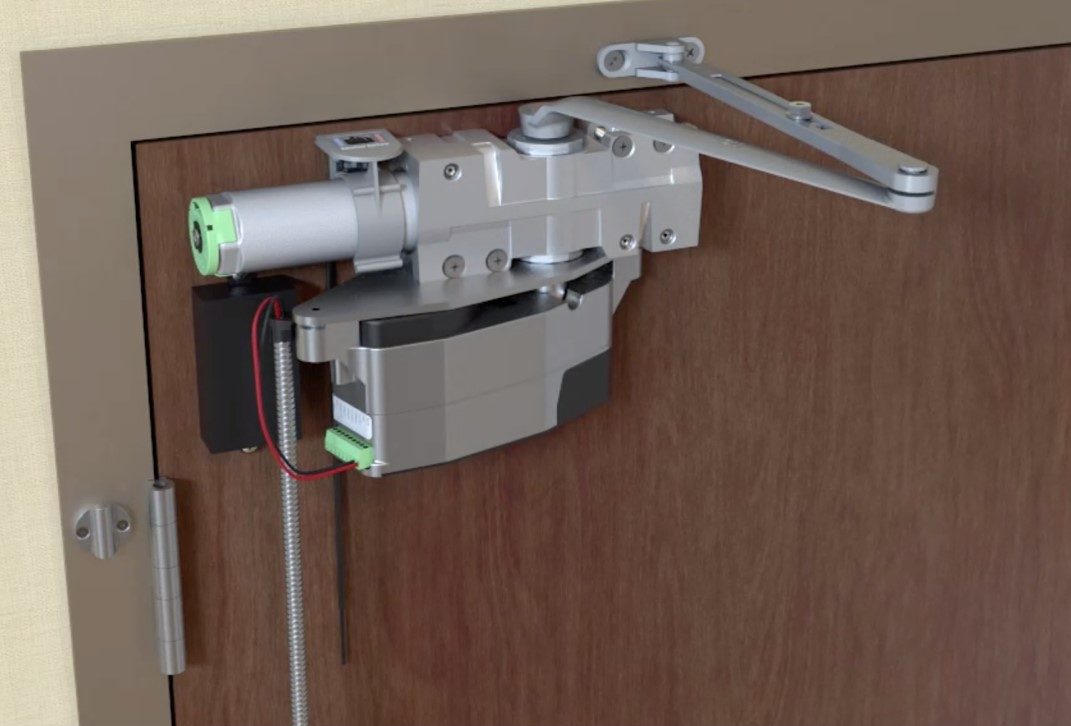

Cost and complexity can be barriers to the installation of a traditional automatic operator, but LCN has created a solution that allows an auto operator to be added to an existing LCN 4040XP door closer. This reduces the cost of the retrofit, as well as simplifying the installation. Check out the video below, download the data sheet, or visit us.allegion.com/lcncompact to learn more.

What do you think?

You need to login or register to bookmark/favorite this content.

Is there a reason not to use one of these instead of a typical auto operator when scheduling hardware?

Hi Travis –

This is a very simple operator, so depending on what features you need, it may or may not be the best operator for your application. I would need to know more about what you’re trying to do.

– Lori

I was just thinking in a general sense, along the lines of durability. I suppose functionality would be the limit in some cases.

I have had an AHJ make the argument that not having the cover on the closer means that you do not have the UL Listed and Tested configuration of a Fire Door. Would that be an issue here> Was the AHJ blowing smoke?

This operator has a cover, but regarding closer covers in general, I can see both sides of the argument. On one hand, the cover is only there for aesthetics – some closers don’t even have covers. The cover does not affect the performance of a door closer on a fire door – the plastic covers melt immediately during a fire door test. On the other hand, where do we draw the line on what can be left off of a fire door without affecting the performance?

I wrote about the closer cover question here, and there were some good comments:

https://idighardware.com/2019/06/qq-closer-covers-on-fire-doors/.

– Lori