Quite a few people have told me that they like the short videos I’ve posted recently (here’s the first, and the second), so here’s another one. Clearly I need to get out more because I’ve had several requests for videos of other applications. Maybe when the rest of my kids go off to college I can start my “van life” and drive around looking for carry bars, swing clear hinges, pocket door closers, and delayed egress locks.

Quite a few people have told me that they like the short videos I’ve posted recently (here’s the first, and the second), so here’s another one. Clearly I need to get out more because I’ve had several requests for videos of other applications. Maybe when the rest of my kids go off to college I can start my “van life” and drive around looking for carry bars, swing clear hinges, pocket door closers, and delayed egress locks.

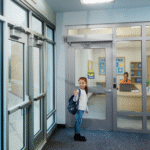

I’m wondering what you think about this door opening…it’s kind of an interesting one as door openings go. It’s the stair discharge for a dorm, leading to the lobby. The upper floors do not include any assembly spaces so the panic hardware is not required, but the door leading from the stairs to the lobby has panic hardware for durability, with no outside trim. The other door has a lockset and an electric strike for access control. You can exit through this door by turning the lever, but most people use the panic hardware instead since the vast majority of traffic is coming down the stairs.

What do you think of this application? WWYD?

Here’s a short video description:

And a few photos:

Here is the pull side…these are Steelcraft Graintech doors (hollow metal doors with wood grain) and I think they look great! But this is a miss…the card reader is to the right of the doors, controlling the electric strike on the LHR leaf, and the entrance to the building is to the left, so everyone using the card reader crosses in front of the door with panic hardware twice before entering the stairwell.

On the stairwell side you can see the panic hardware on the RHR leaf and lever handle on the LHR leaf. I think this is an interesting way to control traffic, as almost everyone coming down the stairs will use the panic hardware, leaving the other leaf for people entering the stairwell.

I know what you’re all going to say…the closer is templated wrong so the arm is wonky. You’re right! But it’s (almost) a good illustration of how the LCN 62A shoe is used to move the closer down to make room for the overhead stop. The top rail of the door should have been a little bit larger to accommodate the stop and the closer.

And by request, here’s a video showing the closer and stop in operation:

You need to login or register to bookmark/favorite this content.

i think 4111’s with s-cush for the closers. those doors more than likely must be rated. the exit device looks to be rated. they should have used an electric lock instead of the strike if it is rated. code or not exit devices are the way to go in dorms.

Looks like the mortise lock’s electric strike and the mortise exit device strike occupy the same area in the mullion. How did that happen? The dust box on the RHR leaf would have to be omitted and the mortise exit device’s latchbolt probably just clears the back of the electric strike. There should be a box enclosing the electric strike too, but that would definitely interfere with the mortise exit device’s latchbolt. Looks like some corners were cut here.

I would have used two rim exit devices (whether needed for exit requirements, or not, because of the abuse they can take) and I would use a low-profile electric strike for ingress access on one leaf. I would have used the Cush arm closer and eliminate the overhead stop. Add a drop plate if needed.

What ever said, I loved this application. It is code compliant and economical. I wonder if the closer Inatallation to clear the OH stop was written on HW Set or was it the installers expertise.

Can say that I much like that arrangement. I realize the door at the bottom of the stair is the left hand door, but there are a few people out there that will always stay to the right and exit the RH door which is this case does not have an exit device.

I’d also want to see what the total number of occupants required to exit the stair is to ensure a 36” door accommodates them. I’m sure it does, but still something to consider.

This whole thing could have been cleaned up using a QEL exit device.

The interference between the closer, the OH stop, and the glazing bead is a good example why I’ve been spec’ing 10″ head sections on doors for years.

I agree with using two exit devices at the interior of the Stair . Although a single panic device and lever handle can facilitate ingress and egress at the Stair, an emergency may warrant exiting thru both doors. Two rim devices would better accommodate multiple Stair occupants exiting the Stair during an emergency.

You’re right, this is an interesting one! I think that double exit-devices makes more sense… but when I think more about what they did here, I wonder if there was some thought put into circulation patterns through those doors; users entering the stair are forced to use the LHR door, and users existing the stair are ‘more likely’ going to use the RHR w/ panic-bar. It kind of forces the circulation/flow of people if there happens to be times-of-day when there are a lot of people using this set of doors at the same time (in both directions).

Should have done the drop plate. They must have missed the note where stops over 3.25″ you mount to the stop effectively needing to move the closer down 5/8″ to avoid that goofy arm application. Though if you did that then the bottom two screws of the closer body would be right on top of the top of the light kit (bottom screws with the stop mount would be 6-15/16″ from top of door by the 4040x62A template and the light kit on a standard FG2 door from Steelcraft starts at 6-31/32 from top of door). I say drop plate for this application to avoid the couple hundred dollar add for non-standard Steelcraft light sizes. But and SCUSH would have solved all the problems.

What is the purpose of installing an overhead stop and a closer on the same door? Can’t the closer also act as a stop?

There are closer arms that incorporate a stop, but a door closer with a standard arm should not be relied on as the means of stopping a door. When a door is subject to high use or abuse, many spec-writers use a door closer with a separate overhead stop if a wall stop or floor stop can’t be used.

– Lori