I know some of you (door closer lovers) will be very excited by today’s Fixed-it Friday special edition!

Nathan Burkhardt of Opening Technologies sent me these photos from a California office building of something I’ve never seen before – an automatic operator on a stall door, with the new style vertical bar actuators:

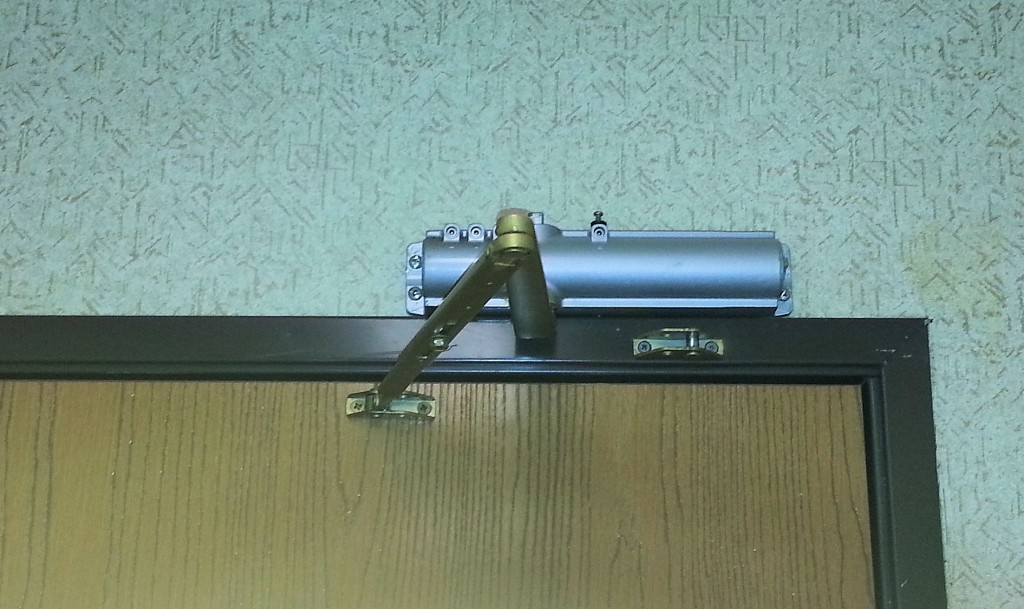

Rich Conroy of Allegion found this poor closer installation. I guess the installer only had drywall screws in his toolbox (and only a couple), and didn’t plan ahead for the trim on the frame.

Jodie Meyers from Phillips-Langley & Associates saw these exterior doors while surveying a school. The old Yale closers and Von Duprin panics (1950’s?) are still working. I see some overhead stops too…maybe GJ 70’s?

Steve Wertman of Allegion found this example of what not to do…

David Moyer of Stanley Security sent me this photo of a nice arched door with the closer mounted incorrectly, and a rock hold-open. Time to call a hardware consultant!

Lee Frazier of Allegion sent me these photos of a “semi-concealed” closer…I hope it never needs to be adjusted or replaced.

David Wiant of Stewart’s Security Service sent these photos of closers mounted on drywall. Bad idea.

Here’s another one from Richard Reichert of Major Lock and Glass Corp…

An epic closer fail, spotted by Glen Buckner of Allegion:

And this one from Dave Bednarczyk of Allegion is for the hard-core closer aficionados…the cush shoe support bracket is installed to accommodate the 5th screw, but the screw is sitting on top of the parallel arm shoe. What’s the point?

You need to login or register to bookmark/favorite this content.

Hello Lori,

ok, you got me reading IDH again, you got my (full) attention this time!

the photos,

1st pic

this is first time I have seen a power operator used on a stall door as well, with this (wall mount) install, are they worried at all about vandalism risk, as I am sure its low enough for a child to reach up and mess with it if they wanted to, nice to also see the new power operator activator bars in use as well.

2 closer pic(closer with drywall screws) that guy must have not really read/understood the instructions, that one I am sure will come loose in time and its not installed on teh FLAT SURFACE of the doorframe, but on the curvy trim. I am sure there will be a callback on that one in short period of time!

another thing I see wrong with the TJ mount, the arm screw that holds the arm to pinion shaft, it’s loose, time to tighten the arm screw!

3rd (school doors with Yale closer and VD panics)

nice finds!! love when schools still have their old original hardware, these closers are the Yale “Compact” 90’s they are still hydraulic, and are adjusted by turning a dial or knob on top of the arm. age of hardware is about right, 50’s and 60’s.

4 (white closer with long forearm) looks like someone was trying to get this one to open a full 180º open and mounted PA bracket near to the hinge jamb to enable this to happen,

did this installer even LOOK at the install directions that came with the (non-Alle) closer? maybe not too graphical to understand?? the way to fix this is to move the frame bracket further away from hinge jamb (may lose some range of motion (max degree of opening, but closer will work better)

another thing I see wrong with that one, the angle of the main arm, (too much pre-load!) when preloading a closer, its put on shaft at 45 degree angle in relative to closer body (when mounted, arm will contact door surface) in this setup, I am sure this closer does not have a latch function (or can close the latch range valve and it will still latch at same rate of speed since the closer’s fluid is only moving though sweep valve.

5. (David Moyer’s arch top door closer) looks like another installerthat did not read about my 4 L’s of door closers (Level being one of them!) a drop plate or corner bracket may be a better option for this closer mounting the body “uphill” or “downhill” can cause premature wear on not only the o-rings, bearings in closer, the rack and pinion teeth (side loading, teeth do not mesh properly inside closer) and arm joints as well. the earlier its fixed, the better the lifespan will be for the closer.

6. (semi concealed closer) this is not the first time I seen this happen, I have met a few of them like this at least 2 or 3 times already, one in an office building when i was younger and the second one was at a campground I went to for Memorial day, I also see the forearm is bent on that one too, evidently it looks like the closers were installed BEFORE the ceilng, many times, closers are some of the final stages of a building renovation or fresh build to prevent this type of thing from happening!

7 (closers on drywall) some of these look familiar, (the shoe locations) silly also how the installer left the previous shoe on the door or on the frame when they installed the (non-IR) product don’t these installers realize that drywall is not as strong as a steel frame??? another one i guess the installer is hoping for a callback to earn more money from fixing loose screws or repositioning the arm

8. looks like someone’s attempt at a pocket door mount, (closer mounts to wall, arm to door) most likely another door closer that didn’t come with the installation instructions or was figuring, “who says you HAVE to follow the directions to the word, I want to do it this way!, if it works, do it”

9. yikes, a LEAKER! do they even know when to replace/fix a leaker where this one is located, not only is it at times gross to see (espeically if fluid is RED in color) but can be a safety (and fire) hazard.

I think its time the owner/user of this building invest in an LCN no-leak closer!

10, (5th hole screw) seems like whoever replaced/installed this closer may have simply forgot when they removed the screw and nut from the closer shoe and put it back on the support so they don’t lose it, then put closer up and only paid attention to the 4 screws at frame and not the 5th hole screw, or does not see the importance of the need for the 5th screw support.

Lori, if it’s OK, can I share this post with the group Door Closer Enthusiasts on facebook?? I am sure they all would get a kick out of this post! 😀

-Jess the door closer doctor

Thanks Jess. Of course you can share the post with the group!

I had a service call to secure a door closer. It was a 4041 installed on a 2″ aluminum top jamb without a drop plate.

Hey Lori! As you know, screwy installations like these are near and dear to my heart. No doubt that Joe Lesniak (my mentor, great friend and best hardware instructor ever) would have really enjoyed these. Its like Joe always said, the crazy thing about most of these “installations” is that – – – they WORK!!???!!

Maybe someone needs to come up with electric latch retraction for toilet partition doors if this concept of a power operator catches on!

Note the threshold on the arched door…

Looks like it was cut for an offset floor check which would be the way to go on this door.

But it turned into “We’re installing X…..”

Safecrackin Sammy,

now that I notice that, it appears they used a “dummy” pivot or maybe a floor closer that was just a torsion spring (I have seen one or 2 on eBay that were super old, B****r hinge company made them) but yes, best bet for a arch top door is use a floor concealed door closer, matter it be #25 or #27 Rixson or Dorma’s series BTS 75v or 80 versions.

if you do not want to use a floor closer as an option, best to use a surface mount closer on a corner bracket, like you see being used with a potbelly door closer when they are used on push side of a door.

if in doubt, best to contact the factory for the proper(special) template code and brackets to mount the closer to arch top door.

as with ANY door closer, best for the closer to be LEVEL for it to work correctly (prevent premature wear and damage to arm or closer or frame)

reminder: if using corner bracket with a door closer (potbelly or modern LCN), hand of closer IS NOT same as hand of DOOR (example: RH door, set up closer as LH)

-Jess the door closer doctor

The inswinging handicapped stall door is interesting. I did have a similar application suggested by LCN engineering for a exterior gate but the track on the gate was inverted to prevent water from collecting in it. Also less likely to get fingers in the track. This picture seems to scream ” not enough room for an outswing door so lets make it automatic”

Dear Sir,

We are a Korean company which specializes in the self-closing door(semi-auto) closer which runs without electric power, opening manually by hand but closing automatically.

Please see the video clip attached.

https://www.youtube.com/watch?v=kw_V2i-d6-Q&feature=youtu.be

Depending on the damping system, two models are available as below.

Item: Self-closing door(semi-auto) device

1) Air damping type

2) Oil damping type

If you have any questions, please let me know..

Thank you

Best regards

Hwasuk Yoo / Export team chief manager

Doornics Co., Ltd.

Phone: + 82 2 3409 2590

Fax: +82 2 3409 2100

Email: doornics@chol.com

http://www.doornics.com

Doornics Co. I looked at your video, the dampeners you use are not New, If you go back and look at the Original Dor-O-Matic Sliders and Stanley Auto Air Swings, that both used these type of Dampeners to control the Open Check and Closing Latch to control the final speeds.

I remember the Stanley Monsters, that had a massive Air Compressor in the building to operate the door openers, you just did not want to stand in the way of them when they work, as there was no semblance of any safety for them, same for the Dor-O-Matic Slider, when it was moving it would cut off a hand if you stuck it in the way of the door panel when opening. This was most common, when a person, who did not understand the principles of the Force of High PSI’s, versus ability to control the flow and speeds.

.