I’m in the process of archiving some older articles and updating the ones that are still applicable…this one was due for an update! This article was published in the October 2013 issue of Construction Specifier and won CSI’s Construction Specifier Article of the Year Award!!

Fire doors are an important part of a building’s passive fire protection system, and doors in a means of egress provide life safety by allowing people to exit quickly when necessary. Still, the requirements remain a mystery for many architects and specifiers.

Fire doors are an important part of a building’s passive fire protection system, and doors in a means of egress provide life safety by allowing people to exit quickly when necessary. Still, the requirements remain a mystery for many architects and specifiers.

Simply put, an opening protective in a fire barrier is required to be a fire door assembly, which includes the door, frame, hardware, and glazing. These components are not typically required to be supplied by the same manufacturer—in most cases, they can be separate products that are listed, labeled, or classified for use in a fire door assembly. Occasionally, an assembly will be made of components that have been tested together and must be used to maintain the rating.

This article addresses some of the basic code requirements pertaining to fire doors, in hopes of making them a little less mysterious. The best way to find the answers is through asking the right questions.

Where can I find the code requirements for fire doors?

National Fire Protection Association (NFPA) 80, Standard for Fire Doors and Other Opening Protectives, is referenced by the International Building Code (IBC), International Fire Code (IFC), NFPA 101, Life Safety Code, and other codes and standards. NFPA 105, Standard for the Installation of Smoke Door Assemblies and Other Opening Protectives, addresses smoke doors and is also referenced in these publications.

Some fire door requirements are included within the applicable building or fire code, but NFPA 80 and 105 are referenced for the more detailed requirements. For product-specific issues, the manufacturer’s listings must be referenced. For example, to find out the maximum fire door size available from a particular manufacturer, one should consult Underwriters Laboratories’ UL Product IQ or Intertek’s ETL Listed Mark Directory.

How can I find out more about an existing fire door?

How can I find out more about an existing fire door?

Each fire door is labeled with a permanent label that must remain legible. Fire-rated frames may have a label or embossment from a listing agency. The door and frame labels contain a wealth of information, including the manufacturer, length of time the component is designed to resist fire, whether the opening is to be equipped with fire exit hardware, and whether the door carries a temperature rise rating or is a smoke door assembly.

Fire door labels often include a number allowing manufacturers to access more information about the door’s original construction. Frame labels may state a fire resistance duration longer than that of the door. In this case, the assembly’s rating will be the lower of the two. Some hardware, such as fire exit hardware, will also be labeled, but the information on the label is typically less detailed.

How do I know what fire resistance rating I need?

The building code mandates the required fire resistance rating of a wall in a particular location, and also states the required rating of the opening protective, or fire door assembly. The fire resistance requirements for various types of fire walls, fire barriers, and fire partitions, as well as smoke partitions and smoke barriers can be found in Chapter 7 of the IBC.

The 2012 edition of the International Building Code introduced new tables on opening protectives, which have been carried forward in all subsequent editions. These tables help clarify the opening protective requirements – for example, the table found in Section 716 states that a two-hour exit enclosure requires a 1 ½-hour fire door assembly, and lists requirements for the glazing used in that assembly. The rating of the door assembly is often less than the required rating of the wall, because it is assumed the door will have a lower fuel load as no combustibles (e.g. furniture, storage, etc.) will be piled in front of the door. If a fire door is no longer needed, it should be removed and replaced with construction of the same rating as the wall to accommodate the potentially higher fuel load.

When are temperature-rise doors required?

Temperature-rise doors are designed to limit heat transfer from one side of the door to the other. If there is a fire on one floor of a building, there may be a need to limit the transfer of heat to the other side of the stair door, so building occupants can exit safely down the stairwell without exposure to extremely high temperatures.

The increased use of sprinklers has resulted in reduced requirements for temperature-rise doors. The IBC requires doors in interior exit stairways/ramps and exit passageways to have a maximum transmitted rise in temperature of 450 F (232 C) above ambient at the end of 30 minutes of exposure, but also includes an exception stating temperature-rise doors are not required in buildings equipped throughout with an automatic sprinkler system.

For the convenience of building occupants, how can fire doors be held open in a code-compliant manner?

For the convenience of building occupants, how can fire doors be held open in a code-compliant manner?

Fire doors must be closed during a fire to compartmentalize the building and prevent the spread of smoke and flames. The intent is to protect the means of egress and allow building occupants time to evacuate safely. If fire doors are blocked or wedged open, they will not be able to do their job and protect the building and its occupants.

There are acceptable ways to hold open fire doors, using electromagnetic holders, or closer/holder combinations that contain integral smoke detectors or are initiated by the fire alarm system. When smoke is detected, the doors close, and provide 20, 45, 60, 90, or 180 minutes of protection. Fire doors are sometimes referred to by a letter designation—A for three hours, B for 60 or 90 minutes, and C for 45 minutes (20-minute doors do not have a letter). However, using the number of minutes is the more common practice.

A fire door with a standard closer and no hold-open capability is called ‘self-closing,’ fire doors that close on fire alarm are ‘automatic-closing,’ and fire doors with automatic operators are called ‘power-operated fire doors.’ Doors in this last category are required by NFPA 80 to become disconnected from power upon fire alarm, so they are manually operable and cannot be held open automatically.

What is positive-latching, and is it required for all fire doors?

What is positive-latching, and is it required for all fire doors?

Hardware on fire door assemblies has to have an active latchbolt to prevent the pressure caused by a fire from pushing the door open and allowing smoke and flames to spread. A springlatch found in a standard lockset or latchset is considered an active latchbolt; some fire door configurations require a specific ‘latch throw’ (i.e. dimension of latch projection).

A deadbolt is not an active latchbolt, because it can be held retracted. An electromagnetic lock does not provide a positive latch, because there is no latching mechanism and the locking is accomplished when the electromagnet bonds to the steel armature. Electric strikes used on fire doors must be fail-secure—that is, when power is cut, the latch is securely captured behind the strike keeper. A fail-safe electric strike could allow the door to become unlatched, so such strikes may not be used on fire doors.

How is fire exit hardware different from panic hardware?

When panic hardware is used on fire doors, it must be fire exit hardware, which is labeled for both panic and fire resistance. A door with fire exit hardware will also have an additional label, indicating that it is equipped with fire exit hardware. Fire exit hardware does not incorporate a mechanical dogging feature—the means to hold the latch retracted using a key, thumbturn, or Allen wrench. For fire doors where a ‘push/pull’ condition is desired, fire exit hardware with electric latch retraction may be used, as long as the latch projects automatically upon fire alarm, to secure the door.

Some vertical rod fire exit hardware for pairs of doors can be installed ‘less bottom rod’ (LBR). These devices use the top rod and latch only, with no bottom rod or latch. The advantage is there is no floor-mounted strike, and no bottom rod or latch to become damaged by carts or traffic. This configuration can sometimes cause a reduction in security, because it may be more easily defeated with only one latching point at the top of the door. In most cases, doors with LBR devices are required to have an auxiliary fire pin, which mounts in the edge of one door and projects into a hole in the edge of the other door if there is a fire.

Do fire doors need smoke gasketing? Are smoke doors also fire doors?

Do fire doors need smoke gasketing? Are smoke doors also fire doors?

NFPA 80 and NFPA 105 do not specifically state that fire doors and smoke doors require smoke gasketing. The key is to check the applicable code or standard, such as the International Building Code, for a limitation on air infiltration, typically with a reference to UL 1784, Air Leakage Tests of Door Assemblies, as the test standard.

For fire doors and smoke doors in certain locations, the air leakage rate of the door assembly shall not exceed 3.0 cubic feet per minute per square foot (0.01524 m3/s × m2) of door opening at 0.10 inch of water (25 Pa) for both the ambient temperature and elevated temperature tests – for most door sizes, this cannot be achieved without smoke gasketing. The requirements for smoke doors and fire doors depend on where they are used. For example, smoke barriers, smoke partitions, exit enclosures, and corridors all have varying requirements for smoke and fire resistance, and the applicable code sections must be consulted to see if a limit on air infiltration is established.

When does a protection plate on a fire door need to be labeled?

NFPA 80 allows non-labeled kick plates to be field-installed on fire doors as long as the top of the kick plate is not more than 16 inches (406 mm) above the bottom of the door. Many door manufacturers have tested with non-labeled plates up to 48 inches (1219 mm) high with no special requirements, but NFPA 80 currently requires a factory- or field-installed plate to be labeled if it extends above the 16-inch mark.

What are the requirements for hinges on a fire door?

NFPA 80 requires hinges and pivots to be steel base material, ball bearing type, and of a certain size, thickness, and quantity depending on the door size, thickness, and fire rating. One hinge is required for each 30 inches (762 mm) of door height or fraction thereof. NFPA 80 includes criteria for the use of hinges or pivots that do not meet the requirements listed in the standard, for example, hinges of a different material, size, or bearing type. Continuous hinges and spring hinges must be tested and labeled for use on a fire door.

Although it may be tempting to use spring hinges instead of a door closer on a fire door for cost and aesthetic reasons, it is important to note that spring hinges do not control a door the way a door closer does, and they need to be adjusted to keep them reliably closing the door over time. In order to avoid having a fire door that either slams shut or does not close and latch, a door closer may be better-suited than spring hinges for most fire doors.

Can existing fire doors be modified for new hardware?

Can existing fire doors be modified for new hardware?

Field modifications are limited by NFPA 80 to jobsite preparation for:

- surface-applied hardware;

- function holes for mortise locks;

- holes for labeled viewers;

- protection plates; and

- a maximum 3/4-inch (19-mm) wood and composite door undercutting.

Holes drilled in the field are limited by the 2013 edition and prior editions to 1-inch (25-mm) diameter, with the exception of cylinder holes that can be any size. Beginning with the 2016 edition of the standard, the size of the round holes is not limited if the holes are part of the listing information for the product’s installation.

For other modifications not specifically addressed by NFPA 80, the listing agency may be contacted through the door/frame manufacturer to request permission to perform a specific modification in the field. Another option would be to transport the existing doors to an approved facility to modify them, attach new labels, and then reinstall the doors. Fire door assemblies can also be inspected and relabeled in the field by the listing agency if acceptable, but this process can be very costly.

What is ‘positive pressure’ with regard to fire door testing?

Positive pressure testing is a method of testing fire doors that more accurately simulates the conditions of a real fire than the test that was previously used—UL 10B, Fire Tests of Door Assemblies, also known as a neutral or negative pressure test. The International Building Code requires fire doors to be tested using the positive pressure test—either UL 10C, Positive Pressure Fire Tests of Door Assemblies, or NFPA 252, Standard Methods of Fire Tests of Door Assemblies, with the neutral pressure level at a maximum of 40 inches (1016 mm) above the sill after five minutes.

The distinction between the two types of tests is particularly important with regard to wood doors. To successfully pass the positive pressure test, some wood doors require intumescent material—either integral to the door or frame construction or applied after manufacturing. The Window and Door Manufacturers Association (WDMA) describes two types of positive pressure openings:

- Category A doors, which require no additional edge-sealing system (intumescent, if required, is integral to the door or frame); and

- Category B doors, which have applied intumescent material.

A wood door specification should state which type of doors must be furnished for the project.

What is a construction label and when would it be used?

What is a construction label and when would it be used?

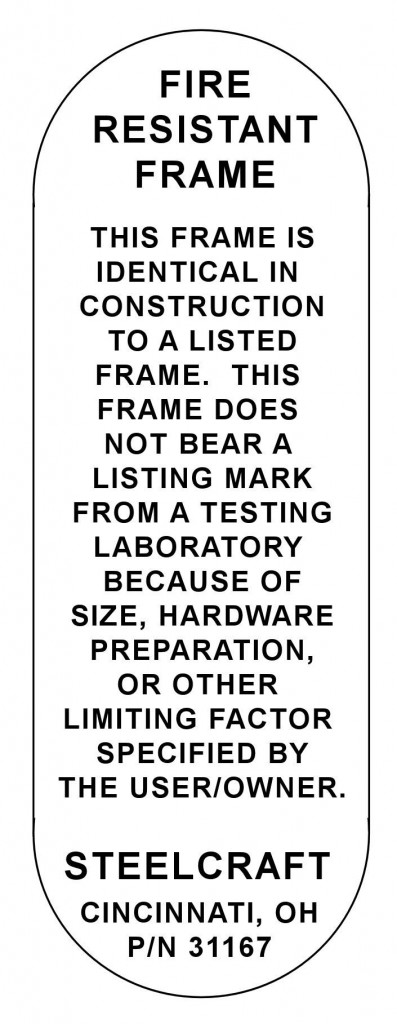

A construction label is applied when a door or frame is used in a location that requires a fire rating, but does not qualify as a rated product. For example, the door or frame may be a size that has not been tested, the jamb depth may be larger (or smaller) than the manufacturer’s listings allow, or the specified hardware may not be included in the manufacturer’s listings. This is not the same as a UL or Intertek label, which certifies the product has been tested to withstand fire for the stated period.

The construction label typically states the door or frame is identical in construction to a listed door or frame, but does not bear a listing mark from a testing laboratory because of size, hardware preparation, or other limiting factor. The construction label does not imply the door or frame is capable of furnishing standard fire protection, but that it is manufactured with the same materials and methods used in the manufacturers’ listings. The label is a means to permanently mark the product so all parties know at a glance the door or frame did not meet the listing requirements. To use a construction label, permission must be granted by the authority having jurisdiction (AHJ).

Are annual inspections of fire door assemblies required for all building types?

Beginning with the 2007 edition of NFPA 80 and continuing with all subsequent editions, fire door assemblies be inspected each year by someone knowledgeable about the requirements. The 2013 edition introduced requirements for fire door assemblies to be inspected after installation and after maintenance work, in addition to annually.

A list of inspection criteria is included in NFPA 80, and written documentation of the inspection must be kept for review by the AHJ. Deficiencies must be repaired “without delay.” This requirement became enforceable when a jurisdiction’s adopted fire code referenced an edition of NFPA 80 published in 2007 or later. Beginning with the 2009 edition of NFPA 101, this code also requires certain egress doors to be inspected annually.

NFPA 80 has always required fire door assemblies to be properly maintained—the 2007 edition just added more detailed requirements and included a specific time frame. Due to improper modifications and lack of maintenance, the condition of many existing fire doors has rendered them unable to perform in the event of a fire. A fire door blocked open with a wood wedge cannot stop the spread of smoke and flames, and damaged latches that have been removed instead of replaced could allow the door to be forced open by the pressure of a fire.

Although a jurisdiction may not be officially enforcing the annual inspection and documentation, fire door assemblies are required to be in good working order. Conducting an inspection and making the necessary repairs can mitigate the risk and liability of having fire doors that will not function properly in a fire. Inspecting newly installed fire door assemblies ensures the building owner has a code-compliant installation to begin with, or allows the deficiencies to be repaired during the warranty period.

The purpose of a fire door is to compartmentalize a building and prevent the spread of smoke and flames. The door shown in these photos protected a nature center and management offices from a fire that began in the maintenance shop. Photos courtesy of Fire Protection Specialist Christopher Taylor, NYS Office of Fire Prevention and Control.

Conclusion

Fire doors can help compartmentalize a building, prevent the spread of smoke and flames, and protect egress routes to allow for safe escape. However, they must be properly specified, installed, and maintained to provide the necessary protection.

You need to login or register to bookmark/favorite this content.

I don’t know who the author is but this article is very nicely done, and would be a GREAT primer for people with very little knowledge of fire doors.

I’m the author, so thank you. 🙂

Great article Lori !! Congrats !!

Would love to recive a PDF version to keep !!

Thanks …

Kahn

Very good article, particularly on the construction rating and temperature ratings. This should be required reading for anyone designing and or preparing drawings.

Thanks Ronnie!

NFPA 80 Article 6.1.3.4 states that the power operator shall be automatically disconnected when a fire alarm occurs so that the doors closes and latches. In your article you mention that the power has to be disconnected which would mean that a handicap person with limited mobility would be trapped with no way to get out of the building without assistance since the corridor doors would need to be opened manually. If you install a fire alarm relay in series with your door hold open circuit this will cause the hold open to drop out thereby closing the door which meets the intent of this Code article. In this scenario the push pad for a power operated door could still be used by a handicap individual just as a person without disabilities can use the handle to open the door. Whats your opinion on this.

Hi Peter – I actually submitted a proposed change for NFPA 80 that would have done what you suggested, but it didn’t fly. Most doors are not required to have an auto operator in order to be considered accessible. But where an operator is used because there isn’t enough maneuvering clearance on the egress side, the operator is required to have back-up power. And if it’s a fire door, power has to be cut on fire alarm, which creates a conflict between the two requirements. Each situation would have to be addressed with the code official because there is no way to resolve the conflict with the codes and standards as currently written.

Here’s some more information on both requirements:

http://idighardware.com/2011/08/auto-operators-stand-by-power/

http://idighardware.com/2011/03/power-operated-fire-doors/

If the limits on holes are 1 inch how is one to install after market locks , I am refering to the lock LKM7000 by Lock Masters it is fire rated for 90 minutes. They have one hole that is an 1 5/8 only on the front side.

In the real world doors and frames are replaced and not in pairs all the time due to cost and that means the hardware may not have been tested with that set up , so does that mean its not fire rated now?

By the way great article!

thanks in advance.

Hi Tommy –

It looks like the 1 5/8″ hole is for the cylinder. If that’s the case, NFPA 80 allows cylinder holes to be of any diameter – they are not limited to 1″.

With regard to replacing 1 leaf of a pair, I would check with the door manufacturer to make sure it’s acceptable per their listings. It may also depend on what the hardware is…for example, LBR fire exit hardware is typically tested in pairs with the auxiliary fire pin, so you would need to keep those as a matched set.

– Lori

Hi Lori,

It has been a while since we have spoken, I hope all is well.

Interesting part about the protection plate. I never knew that an armor plate could be labeled. I ran into this problem when we installed 46″x 48″ armor plates onto rated doors. They were rejected because they didn’t have labels on them. There were 20 or so with bottom rods attached to them.

The owner hired a third party door inspector who commented on this condition and put into his report that this was a fire code violation. We had a real mess on our hands! The same inspector suggested and accepted the plates after we add an adhesive between the door and plate.

Since this incident I use adhesive any time I install a plate larger then 16″ onto a labeled door. Do you know if this is an acceptable practice?

Thanks, JOBIII

Hi Joe! Yes, it’s been a while!

I don’t know that adhesive is a viable alternative to a labeled plate, but if you tell me who the 3rd party inspector was, I can ask where he got that from.

– Lori

I do not recall what his name was. I try to make the suppliers I am installing for aware of this all the time. Hospitals seem to run into this condition quite a lot.

Just be careful because as far as I know, using adhesive doesn’t solve the problem. I would used labeled armor plates until we eventually get a code change on this issue.

Ill be sure to pay attention to this. Thank you for the feed-back Lori.

very helpful article! thank you Lori!

Hello Lori, Thanks for the article It was truly helpful.

1 Question. It stated holes of 1″ can be made so does that mean each hole or a sum of all holes should not exceed 1″?

Asking for hardware mounting like screwed in kick plates, closers…

Hi James –

Each hole can be a maximum of 1-inch diameter. There isn’t a stated limit in the standard on the number of holes.

– Lori

Excellent – Then it seems I can apply a screw mounted kick plate and not alter the UL listing. Your awesome!

What are the requirements for glass-lites in fire doors and can you please explain?

Hi Joyce –

Most fire doors require fire-protection-rated glazing. The allowable size of the vision light depends on the listings of the door manufacturer, the type of glass, and the rating of the door. If you have a specific question, let me know.

– Lori

We are considering installing handicap operators on our restrooms doors at our church. The doors are fire rated doors. Are we allowed to install the operators on fire doors, or are we limited to installing electromagnets which hold the doors open and release, shutting the doors when the alarm is triggered?

Hi James –

It is acceptable to install automatic operators on fire doors as long as the operator is listed for use on a fire door (tested per UL 10C / NFPA 252). You will need to coordinate releasing the latch in order for the door to open – probably with an electric strike. During a fire alarm, NFPA 80 requires the automatic operator to be deactivated.

– Lori

Lori thanks for this valuable information, I am involved in the design of a fire rated door and we are trying to find if there is any information about hinge placement, could they be surface mounted? Thanks!

Hi Cynthia –

There are surface-mounted hinges available that are listed for use on fire doors – just check with the door, frame, and hinge manufacturers to make sure the installation you have in mind is acceptable per their listings.

– Lori

Hi Lori,

Great article!

Can we get more information on smoke doors versus fire doors? Would a 20 minute smoke door scheduled with panic hardware need to have a fire rated exit device?

Hi Tina –

I think a lot of the confusion comes from the fact that people think of 20-minute doors as “smoke doors” when they are actually fire doors. A 20-minute door has to comply with NFPA 80 (smoke doors do not), so if the door has panic hardware it needs to be fire exit hardware.

– Lori

Hello Lori,

Your article mentions “protection plates” are acceptable contingent upon size / rating requirements. Would protection plates allow for surface mounted edge guards to be installed in the field on exg rated doors?

Thanks!

Hi John –

The edge guards are not specifically addressed by NFPA 80 or the model codes. I would recommend checking with the door manufacturer to see what their listings will allow.

– Lori

This is fabulous tip for all of us who has no idea about that. Thanks very much for sharing this important trick with all of us. I really liked your blog.

Lori,

Do you have any resources regarding UL listed Door Position Switches, and more specifically is field modification of a rated door and frame permissible for Listed Door Position Switches?

Thank you

Dan

Hi Dan –

I know we have some that are listed – here’s the data sheet: https://us.allegion.com/content/dam/allegion-us-2/web-documents-2/DataSheet/Schlage_Door_Position_Switch_Data_Sheet_105005.pdf.

What I have been told by UL is that if the installation instructions show a prep for the switch, and it is a round hole of 2 inches or less, it can be prepped in the field without affecting the listing of the door or frame.

– Lori

NOT MUCH IS MENTIONED ABOUT APPLIED PANELS TO THE FACE OF A FIRE RATED DOOR.

OR INLAID METAL STRIPS/REVEALS IN THE FACE OF FIRE RATED DOORS.

ARE THERE SPECIFIC GUIDELINES THAT SHOULD BE FOLLOWED PERTAINING TO THIS?

Hi Stuart –

What is allowed for cladding would depend on the listings of the individual door manufacturer. This article might help: https://idighardware.com/2020/07/qq-cladding-on-a-fire-door-assembly/.

– Lori

2022 now. Still a great article. still totally on point

Very informative anyway you have an article pertaining to electronic strike requirements

Gary Gayhart November 2, 2023

Lori,

I work in Detention Group I-3 facilities. We have varying opinions on the fire doors. My opinion is that the detention swing doors have an electromechanical half cycle lock and must have a mortised detention latch installed in the door. The opposing opinion is that the half cycle lock can be set in an emergency to continuously full cycle. I contend that this operation does not maintain full time positive latching

Hi Gary –

I have not worked a lot with detention hardware, but I don’t know of an exception that would allow a fire door without positive latching in an I-3 occupancy. If anything, fire doors that are closed and latched are even more important when evacuation is not possible during a fire.

– Lori

Hey Lori,

Have a question on fire rated interior steel store front doors made by TGP they are non ax model 33 SVR exit devices and since I’m in California I’m getting the inspector saying I don’t meet the 5 pound push for ADA but I tell him they are rated and meet the 15 pound push for a rated opening (we are at 10 pounds) do we still have to meet ADA requirements or am I not understanding something any help would be appreciated

Hi Robert –

Fire doors are exempt from the 5-pound limit of the accessibility standards for opening the door, but they are not exempt from the force limits for operating the hardware. In most of the U.S., the limits of A117.1 and the IBC are used – 15 pounds of push/pulling motion (like panic hardware) or 28 inch-pounds of rotational motion, but in California the 5-pound limit is typically used.

– Lori

What’s the difference between listed, labeled and classified?

Ok since I did not comment between 2013 to 2024,

Comment

Great article.

I think you said you are working on updating the

“Code Reference Guide “

But some codes never change, so still a good starting point reference

Download or order::

https://idighardware.com/guide/

I can’t believe you didn’t comment until now, Charles! 🙂

– Lori

Hi Lori,

Great article as usual.

Is there any push to change what a labeled shop can do in the field? If we’re authorized to label and modify fire doors for a particular manufacturer in our shop, why SHOULDN”T that authorization allow us to perform the same work in the field? We all know that this type of work happens frequently. I’ve worked at distributors that will remove the door from the site, take it to the parking lot and modify the door in their trailer (“an extension of their shop”). I’ve worked at other places that actually do the work in the field without trying to hide it and only one company that actually followed the rule of law and carried the door back to their shop.

It really doesn’t make sense to me why the work MUST be done in the labeled shop. Let’s take a missing door label for instance. What is the point of detaching the hardware (think electric hinge or EPT, auto-operator, continuous hinge, etc.), removing the door, hauling it down 6 floors (risking damage), loading it in a truck/van, unloading it into the shop, adding a fire label (which takes 20 seconds) and sending it back to the field? If we provided the door with the label and we can confirm the door is in the correct location, why not just bring a label to replace the one the painter removed and forgot to re-attach. This happens very frequently.

I’ve been in this field for over 30 years and have never understood the reasoning for only performing this work in the authorized shop. NOTHING is done differently in the shop vs the field.

To go a step further – the agencies that can be hired to perform field work don’t really do their due diligence to verify that the doors they work on are actually allowed to be modified. They ask us (the distributor) to provide all of the pertinent information to prove the door/frame is authorized to be modified as requested. When they arrive on site, they simply watch someone else do the work – they don’t actually do it themselves. They don’t have any way of confirming that the door/frame we take them to is the actual door we provided the information about.

I don’t recommend this and I know the danger in doing so, but I would bet I could get them on site to label a 45 minute door with a 90 minute label and they wouldn’t know the difference. As long as they get paid, they will apply the label based on the info I provided. What would cost an authorized shop about $15 plus a trip charge ends up costing $1,500 for an agency to send someone to witness us drill a hole (or whatever needed to be done).

Hi Eric –

I don’t disagree with you on this, but I haven’t seen anything official that really answers this question. I did notice a change in the 2025 edition of NFPA 80, it now says: Field labeling shall be performed only by individuals or companies that have been certified or listed, or by individuals or companies that are representatives of a labeling service that maintains periodic inspections of production of labeled equipment or materials and by whose labeling the manufacturer indicates compliance with appropriate standards or performance in a specified manner.

The question is how to get certified or listed.

– Lori