Many of us have experienced a project where the doors were subjected to unexpected wind loads, causing problems with the hardware and the operation of the door. I’m not talking about the occasional wind that comes with a hurricane, tornado, or tropical storm – I mean the everyday wind gusts due to the building location or other factors.

Many of us have experienced a project where the doors were subjected to unexpected wind loads, causing problems with the hardware and the operation of the door. I’m not talking about the occasional wind that comes with a hurricane, tornado, or tropical storm – I mean the everyday wind gusts due to the building location or other factors.

One of my projects with a wind problem was a hotel in downtown Boston. Just as construction ended, someone opened an exterior door to the lobby and it was whipped out of their hand by the wind. This building isn’t right on the water, the door is at street level, and we weren’t in the midst of a hurricane. I had no way of knowing that wind would be an issue, and even if I had, I’m not sure I would have initially been able to talk the architect into the solution we ended up with – a heavy-duty surface mounted closer with a separate overhead stop.

Someone recently contacted me about a door that had been subjected to 60 MPH winds and had injured someone. The question she asked was whether there were code requirements pertaining to the opening/closing cycle of doors in windy conditions. As far as I know, there aren’t. The only thing that comes close is the accessibility requirement which states that the maximum closing speed must be 5 seconds to go from the 90-degree position to 12 degrees from the latch. I don’t know how this would be applied to a door caught by a sudden gust of wind.

My recommended solution was a heavy duty cast iron closer with a separate heavy duty overhead stop. Advanced Variable Backcheck (AVB), which starts the cushioning effect of backcheck earlier in the opening cycle, could help if the door was being whipped open by the wind, but would also make the door more difficult to open. This might be a solution for some doors, but I wouldn’t use it on the main entrance.

So…

- What would you do to improve the situation if a door is being slammed closed by the wind or blown open by the wind? Keep in mind the opening force limitations of the accessibility and egress requirements.

- And what about pressure relief valves (PRV)? The one I tested in the lab would allow the door to slam closed or fly open as soon as I applied abrupt pressure to the door. I wouldn’t want a closer with a PRV on a door in a windy location.

- Finally, whose problem is it when the hardware you specified is not able to withstand the unexpected wind loads? Is it the hardware consultant’s responsibility to pay for the solution? The architect’s? Is there some way to determine in advance that the wind will be an issue?

I’d appreciate your feedback!

Here’s what 40MPH winds look like (no, this is not me):

And a glass door battling high winds (and losing):

And here’s one more broken glass door which has nothing to do with wind but will provide some entertainment value:

You need to login or register to bookmark/favorite this content.

Lori,

do you post the comments/solutions for these type questions..

I’d like to hear what others do.

Russ

Hi Russ –

Yes, hopefully people will leave comments and I will publish them. I sometimes add to the original post.

– Lori

hey lori! balanced doors are becoming more & more popular in korea for the efficiency & mechanical advantage despite the high cost. i hate to admit it but sometimes there’s only so much we can overcome relying on just the door hardware aspect 😉

http://youtu.be/5JcyIiHGLFA

Thanks Tony. Balanced doors could be a good option if the wind condition is known in advance.

We always specify continuous hinges, overhead exposed heavy-duty closers w/heavy-duty rigid parallel arms, and overhead concealed stops at aluminum storefront entrance doors.

Most architects do not like the like the appearance of the exposed closers, but this combination seems to work on school projects in our area.

Hi Lori! I think you used every available option for your particular situation with the exception of an additional positive stop, either wall or floor, which brings me to my question: considering the circumstances, which is more hazardous: an uncontrolled door due to high winds or a tripping hazard from an exterior floor stop? You didn’t mention stop arms on closers but most manufacturers will state in their catalogues that an additional positive stop is required in conjunction with stop arms so it’s kind-of redundant.

Hi Eric –

I used an overhead stop so that there wasn’t a floor stop to trip over. I use closers with integral stop arms a lot, but for high winds I would go with a separate overhead stop like the Glynn Johnson GJ90.

– Lori

Lori, we had wind tunnel testing done for a campus in a windy bayside location here in SF, and it helped us choose not only the locations and shelter of doors but also outdoor seating and gathering spots. I think the mechanical engineers used it, too, to predict stack effect. I highly recommend the design assistance. We chose balanced doors at the time, but with California’s tight opening-force restrictions we also often choose power-assist and power-operator devices. Lately, the architects I work with have gone by gut and experience, but a wind study saves a whole lot of guessing and post-construction redesign. When you’re part of the design team, consider asking for a wind study.

Thanks Vivian! Would the hardware consultant ever be expected to have the wind study conducted or would it always be the architect or engineer’s responsibility? I guess what I’m asking is…if there is a door problem after the building is constructed, what is the hardware consultant’s liability if he or she was not told that the doors would be subject to a high wind load? And what’s a ballpark figure for the cost of a wind study?

I don’t know the cost of a wind tunnel study, but it’s the architect who has the information (or a physical model) needed to conduct one. I’ve never heard of a door hardware consultant initiating one, though an envelope consultant might. One hopes that if you ask for a wind study they already have one, or they have useful information like historic wind speed data or measurements at nearby buildings.

Not being told about high winds is a risk, one that should be averted if you ask. If you get incorrect or insufficient information, that paper trail should help.

Hi, Lori! I think it would be very unusual for the door hardware consultant to commission the wind study, because it’s the architect who’ll have all the data and will have more than one use for the results. (It requires either a physical model for the wind tunnel study or the building configuration to create one.) An envelope consultant might be another party who might commission or conduct the study, but generally it should fall to the architect.

Rather, I think asking for the study reduces your risk in a couple of ways: if there is one already, you get to use it, or, if there isn’t, you’ve started a conversation about wind. If there’s no wind study, hopefully the architect has looked up local wind data or gotten measurements at nearby buildings with similar exposure. In many cases, that’s plenty of information; we did our wind tunnel test because there were no existing buildings on the site or with the same exposure as our campus. In a dense city like Boston, measuring the neighbors’ wind speeds at entrances and around corners might have been enough. Now, if you are given insufficient information or incorrect information, you have a paper trail, but hopefully you’ve gotten information you can use to recommend a viable solution.

I don’t know the cost of a wind tunnel test, but a quick glance at my LinkedIn connections seems to suggest that I could find someone who does. Shoot me an email if you still want to explore that.

Lori, interesting that the Boston hotel you featured is close to where the first door closer was invented by Lewis Carey Norton (L.C.N.) in 1876. Norton went to Boston, Massachusetts, to help build the Trinity Episcopal Church. The church was constructed on the Back Bay facing south and west, in the path of powerful sea winds which closed the new church’s doors with thunderous banging sounds. The Rector told Norton that he was not going to stand for all that noise! The doors needed to be controlled. Norton dedicated himself to finding a solution, and he did!

You’re going to love a post that I have coming up! 😀

don’t forget me as well, biggest fan of door closers many brands, including LCN

Lori: i have a feeling this next post of yours has to do with YOUR closer and/or NEDC….. can’t wait to see the pictures of what happened.

Kathi, nice summary of the history of the Norton Door check & spring!!

and yes, Boston is the birthplace of the first door closer

(and now I have a few leaky door closer questions waiting for me, one LOCAL)

-Jess the door closer doctor

I would never forget you Jess!

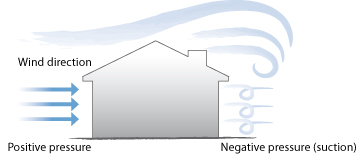

Wind effects can be calculated to a certain extent. Formulas are available. The codes spell out the basic numbers and the formulas show the affects (increase/decrease) on the various faces and surfaces of the building. Architects and structural engineers should be taking these into account since there are other building elements beside doors and hardware which are affected. Wind tunnels are used if the surrounding buildings or terrain make basic calcs complicated. If forces beyond the normal are anticipated the architect has a responsibility to keep all memembers of the design team informed. But that aside nobody is responsible for winds (tornados, micro bursts) that are beyond the code mandated forces.