This post was published inDoors & Hardware

As the price per square foot of real estate rises, sliding doors are becoming more popular in business, residential, and health care occupancies. While swinging doors require approximately 9 square feet of floor area to accommodate the door’s swing, almost no floor space must be dedicated to the operation of sliding doors, which run on the face of the adjacent wall or even inside of the wall (pocket doors).

Manually-operated sliding doors are not always allowed in a means of egress, since the model codes require side-hinged or pivoted swinging doors for most locations. The International Building Code (IBC) currently contains 9 exceptions where swinging doors are not required and other types of doors are allowed:

- Private garages, office areas, or factory/storage areas with an occupant load of 10 or less

- Detention areas (I-3 use group)

- Some types of patient rooms within suites in a health care facility

- Dwelling units in residential use groups R-2 and R-3

- Revolving doors complying with the applicable IBC section, except in high hazard occupancies

- Special purpose horizontal sliding, accordion, or folding door assemblies – power-operated doors that are usually in the open position but may close upon fire alarm – except in high hazard occupancies

- Power-operated doors with the breakout/breakaway feature

- Bathroom doors in residential R-1 dwelling units

- Manually-operated horizontal sliding doors serving an area with an occupant load of 10 or less, except in high hazard occupancies

Item 9 addresses manually-operated horizontal sliding doors, and limits their use to doors serving an area with a calculated occupant load of 10 people or less, in any occupancy with the exception of high hazard occupancies. Many of the requirements for manually-operated sliding doors are the same as those for swinging doors, but it’s important to know where they differ:

Opening Force – According to the accessibility standards, opening force for manually-operated sliding and folding doors is limited to 5 pounds of opening force, maximum. This limitation does not include the force required to release the lock or latch.

Clear Opening Width – The minimum allowable clear opening width for a sliding or folding door that is part of an accessible route is 32 inches. Projecting hardware that prevents the door from sliding completely open will affect the clear opening width.

10-inch High Flush Bottom Rail – Sliding doors are exempt from the requirement for a flush, smooth area extending from the floor to 10 inches up the face of the door. This requirement applies to the push side of manual swinging doors.

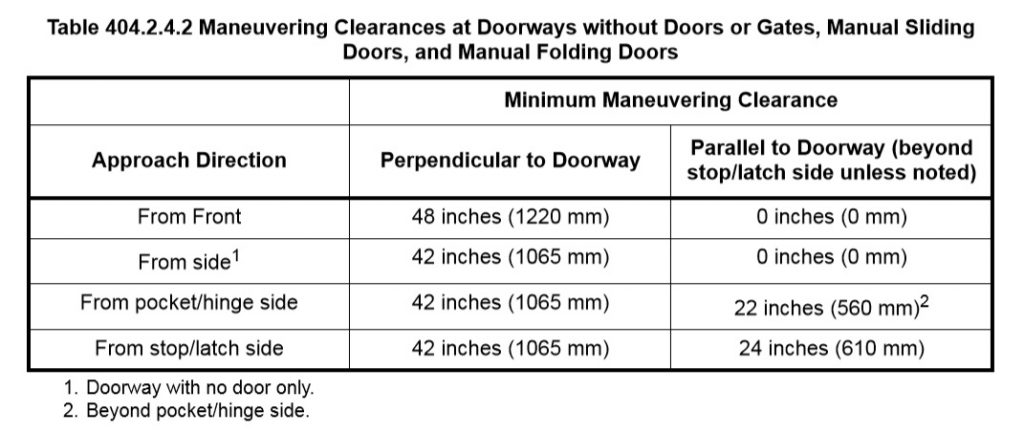

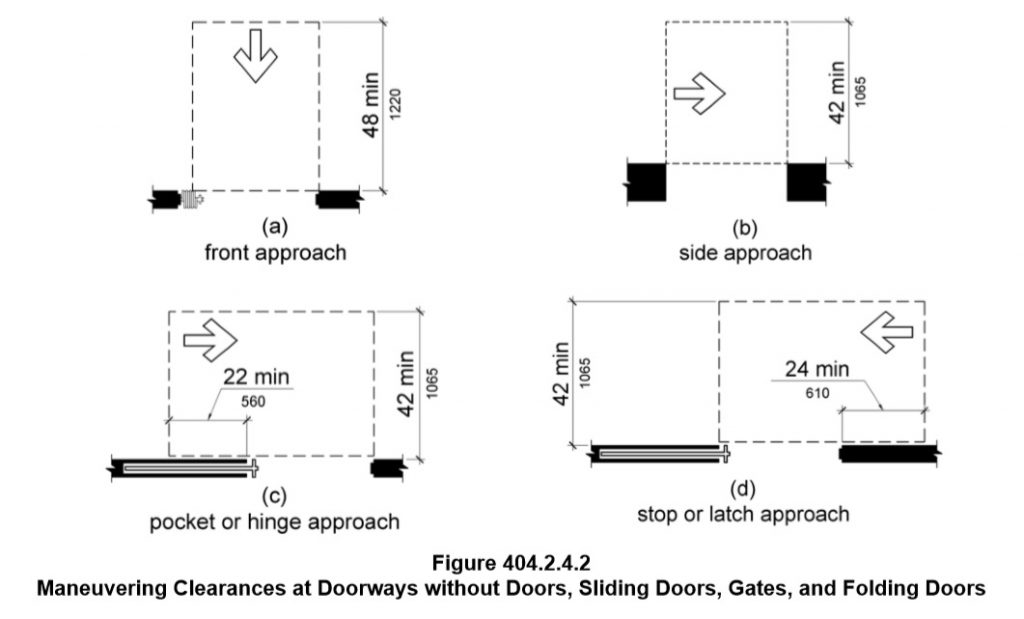

Maneuvering Clearance – The maneuvering clearance required for sliding doors is different from the amount of clearance required for swinging doors, because of the method of operation and the fact that there is no need to maneuver out of the path of the door swing. The ADA standards (free download here) include a table and graphics to illustrate the required maneuvering clearance for sliding doors, as well as folding doors and doorways without doors:

Hardware – Operable hardware on sliding doors must be operable without tight grasping, pinching, or twisting of the wrist, with a limited amount of force, and must be mounted between 34 inches and 48 inches above the floor. One releasing operation must unlatch the door for egress. In addition, the hardware must be exposed and usable from both sides when the sliding door is in the fully-open position. In the past, sliding pocket doors often had an edge pull which required dexterity to operate, and the door would slide all the way into the pocket. Most Authorities Having Jurisdiction (AHJ) do not consider a traditional edge pull operable without tight grasping or pinching, and when the door is in the pocket, the hardware is not exposed and usable from both sides.

To comply with current accessibility requirements, sliding doors are often equipped with surface-mounted door pulls on each side of the door. These pulls prevent the door from sliding all the way into a pocket or completely out of the opening if it’s a sliding door mounted on the face of the wall. When the door is fully open or fully closed, there should be at least 1 1/2 inches of space between the door pull and the frame, as well as behind the door pull. The 1 1/2-inch dimension is a recommendation that is found in the US Access Board’s online Guide to the ADA standards. Keep in mind that the surface-mounted hardware and required clearance will affect the clear opening width when the door is in the fully-open position. Updated pocket-door locks incorporating a retractable edge pull are available, which do not require tight grasping, pinching, or twisting of the wrist and may be acceptable to the AHJ.

NFPA 101 – Life Safety Code

The requirements of NFPA 101 vary slightly from those of the IBC and the referenced standards, so it’s important to refer to the specifics of the codes that have been adopted in a project’s jurisdiction. Similar to the IBC, NFPA 101 requires doors serving most egress routes to be swinging doors, but includes some exceptions in the occupancy chapters. These exceptions include door assemblies meeting the required criteria in dwelling units (Chapter 24), residential board and care occupancies (Chapters 32 and 33), horizontal sliding or vertical-rolling security grilles or door assemblies (Chapters 11 through 43) and horizontal sliding doors in detention/correctional occupancies (Chapters 22 and 23). The code also addresses special-purpose horizontally sliding accordion or folding doors, vertical-rolling door assemblies, revolving doors, and existing fusible link operated fire doors (Chapters 39, 40, and 42).

Horizontal-sliding doors are allowed by NFPA 101 unless prohibited by the occupancy chapters, as long as the door is not serving an area with a calculated occupant load of 10 people or more. The room served by the sliding door must not have high hazard contents, must be readily operable from either side without special knowledge or effort, and the force required to operate the door must not be greater than 30 lbf to set the door in motion and not more than 15 lbf to open the door to the required width or to close the door. The code includes additional requirements for sliding fire doors and sliding doors that are required to be self-latching, such as doors in a health care corridor.

Current accessibility standards require operable hardware for sliding doors to be exposed and usable from both sides when the sliding door is in the fully-open position.

Flush pulls and edge pulls that were once common allow pocket doors to slide completely into the pocket and require a high level of dexterity to operate. This hardware is not generally considered compliant with current accessibility standards, although there are updated pocket door lock designs that may be acceptable to the AHJ.

You need to login or register to bookmark/favorite this content.

I had a home assisted living install

Rated sliding doors

The state assisted living inspector wanted latching hardware.

Owner had a hard time finding hardware

They used something like this::

http://www.trimcohardware.com/products/latching-locking/sliding-door-hardware/trimco-1069-series-ada-pocket-door-pulls/

WOW! A wonderful post! I can’t wait for your ShortCodes series!

The calculated Occupant Load (OL) based on the room’s, space’s, or area’s “Function of Space” and the correlating Occupant Load Factor (OLF) will determine whether or not a manual sliding door is allowed in the Means of Egress and not the occupancy of the building. A conference room with a “Function of Space” of “Assembly – Unconcentrated (Tables and Chairs)” in a Group B Business occupancy would be limited to 135 sf maximum area and would have a calculated OL of (9) occupants based on an OLF of 15 sf/occupant. (135 sf / 15 sf per occupant = 9 occupants). An office suite with a “Function of Space” of “Business Areas” and an OLF of 100 sf/occupant would be limited to 900 sf maximum (900 sf / 10 sf per occupant = 9 occupants) if a single manual sliding door was desired.

I made a couple of tweaks to clarify that the exceptions in the IBC and NFPA 101 are based on the calculated occupant load, not the actual number of occupants, and added a link to my Decoded article about how to calculate the occupant load. Hopefully that clears it up.

– Lori

What about flush pulls like this? With a push of a button a grip handle emerges from the edge of the unit:

http://www.accuratelockandhardware.com/home?lightbox=image_1k9z

The “Tight Grasp or Twist” statement is somewhat nebulous, but this product seems to meet the intent (never had it rejected by the AHJ).

I would say that technically that product does not require tight grasping, pinching, or twisting of the wrist, and while the hardware on the door face is not visible and operable while the door is in the pocket, you could project the edge pull by pushing the button. If the AHJ took the time to think about the intent, I think it does meet the intent although at first glance it might not seem to.

– Lori

IBC 1010.1.4.4 Security Grilles (Group B, F, M & S) may be used at the main exit if secured open when occupied.

I’ve used the Trimco 1069 on a commercial office project, but was a bit disappointed. It lacks heft/ feels flimsy/ hooks loosely. Just my opinion. Not that there’s a wealth of better solutions.

Where is it stated (in a code, standard, or reference) that the pulls require the 1-1/2″ clearance on either side of the surface pull? I have been “dinged” for using a flush cup pull, and have changed to surface pulls back-to-back, but have never seen this stated in writing.

It’s not clearly stated in any code or standard that I know of, but based on the ADA Guide (http://idighardware.com/2015/08/guide-to-the-ada-standards-chapter-4/), 1 1/2 inches of clearance is recommended. If the pull is tight against the jamb, it’s difficult to operate. I have had some AHJs interpret this the same way – 1 1/2 inches behind the pull, and 1 1/2 inches between the pull and the jamb.

– Lori

Todd Wyatt, I think your math is off. Because 10 occupants are allowed, 150 SF would be the area limit for that function.

I have to agree here it does say “10” not up to 10

It is also important to note that most patient rooms require an STC rating, not just for the door slab but track system as well. They must also seal for sight lines. If you would like some more information please feel free to contact me. Jaret@serenityslidingdoor.com

Are there opening speed requirements in the NFPA 101 for an overhead coiling door as a means of egress in an S-2 occupancy with less than 10 people? I could not find any requirements. If NFPA 101 does not give any opening requirements would we defer to the IBC requirements, if any exist.

Is hardware required at the bottom of the door to keep it from swinging outward?

Hi Lance –

That’s a good question but I have not seen anything in the codes that requires that. From a functional standpoint it would be a good idea, and it would likely be required per the listings if the door was a fire door assembly.

– Lori

– Lori

I have a sliding door from my living room to my porch an stairway leading to back exit of building. The door is incredibly hard to close. It is a very heavy older style door. It has sometimes gotten stuck trying to close, or fallen slightly of the track at the bottom. It’s frame around the latch is mangled from what looks like a forced attempt to enter or exit apartment. To lock the sliding door from the inside is often challenging with the door not always closing fully to be able to use the latch, which is a inset latch requiring one finger to press up. The door is so old it no longer properly alines with the frame leaving a clear gap on topside, which you can put a finger through an you feel the cold air rushing in during the winter.

I can imagine the trouble you’re having, Peter! Sliding doors look cool and take up less floor space, but they can be tough to keep operating properly.

– Lori

I am working on a small, single story medical clinic. It is unlocked during business hours and locked at night. It has a single sliding aluminum door at the inner and out side of the main entry foyer. They each have a mortise style deadbolt (hook) lock operated by key on the outside and thumb turn on the inside. The building may have a cleaning crew(1 or 2) after hours.

The thumb turns were called out as a safety hazard due to the ability of anyone to lock the doors during day hours. The solution offered was to make key required from both sides, but now egress would be impeded at night. What is the correct solution?