I originally wrote this article in 2012(!), and when someone asked me a question about this topic yesterday, I noticed that the post needed an update. Current information from the model codes and NFPA 80 is now included.

This post was published in Doors & Hardware

Vertical rod fire exit hardware for pairs of doors is available with top and bottom rods and latches, or with the top rod and latch only; this application is known as “less bottom rod” or “LBR”. Eliminating the bottom rods and latches can help to meet accessibility requirements and also allows the floor strikes to be omitted, but security may be affected so the application should be carefully considered. LBR devices have been available from most panic hardware manufacturers for more than 20 years, but I still receive questions about them occasionally – either related to the use of the product on fire doors, or their installation on doors in a means of egress.

Past editions of NFPA 80 – Standard for Fire Doors and Other Opening Protectives did not specifically address less bottom rod fire exit hardware; a clarification has been added to the 2022 edition. The standard requires fire doors to be equipped with an active latch bolt to ensure that the door is positively latched during a fire. Panic hardware used on fire doors must be fire exit hardware, which is not equipped with the mechanical means to hold the latch retracted (AKA “dogging”), and must bear labels from the listing agency for compliance with both panic and fire test standards.

Past editions of NFPA 80 – Standard for Fire Doors and Other Opening Protectives did not specifically address less bottom rod fire exit hardware; a clarification has been added to the 2022 edition. The standard requires fire doors to be equipped with an active latch bolt to ensure that the door is positively latched during a fire. Panic hardware used on fire doors must be fire exit hardware, which is not equipped with the mechanical means to hold the latch retracted (AKA “dogging”), and must bear labels from the listing agency for compliance with both panic and fire test standards.

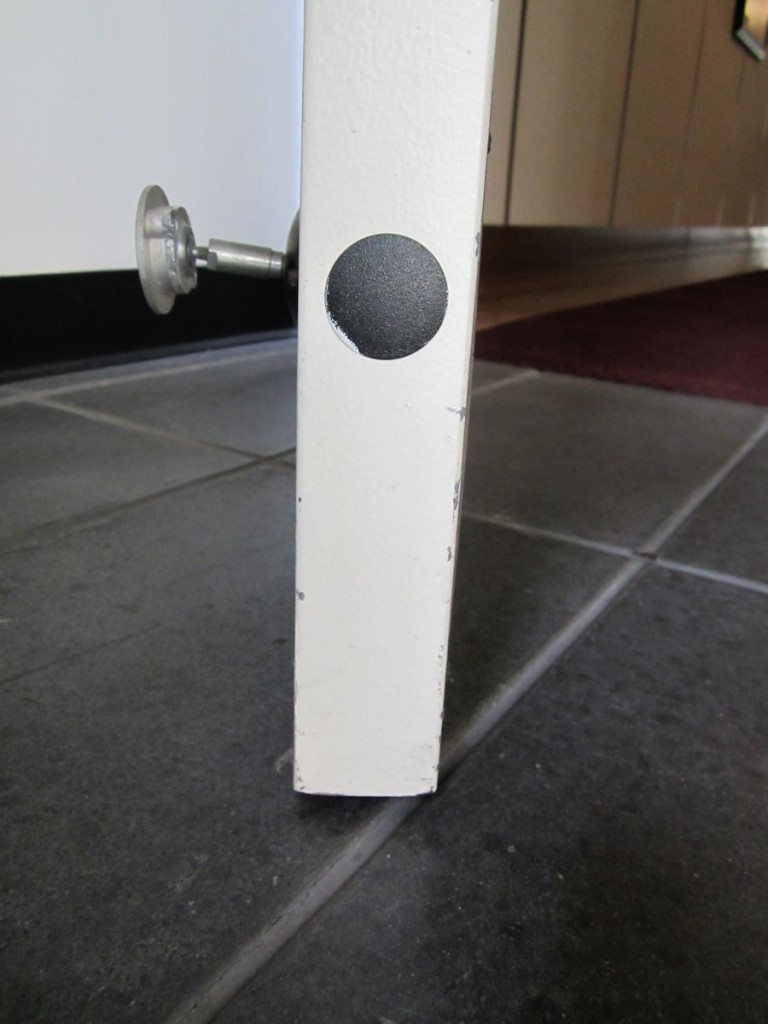

Less bottom rod fire exit hardware has been successfully tested for use on fire doors, and the specifics can be found in the manufacturer’s literature or the listing agency’s directory of certified products. For most applications, an auxiliary fire pin is required in order for the doors to maintain their fire resistance rating. This pin typically mounts between 6 inches and 12 inches above the floor, on the edge of the door, although some manufacturers may have tested their LBR devices without an auxiliary fire pin, or with pins mounted in the bottom edge of the door. The pins remain retracted under normal conditions, and are heat-activated. When the temperature of activation is reached – usually around 400 degrees, the pin projects from the edge of one door into a hole in the edge of the other door leaf (or into the floor if the pins are installed on the bottom of the door). In addition to fire exit hardware, these auxiliary fire pins are sometimes used on fire doors with automatic flush bolts, when the bottom flush bolt is omitted.

The auxiliary fire pin has raised concerns about egress in the past, because once the bolt is projected, the doors no longer allow free egress. It’s important to understand that the pin projects only during a fire, and its purpose is to maintain the alignment of the doors to prevent the spread of smoke and flames. According to Underwriters Laboratories, an auxiliary fire pin with an activating temperature of 400 degrees typically projects 15-20 minutes into a fire test, when the temperature inside the test furnace is approximately 1,400 degrees Fahrenheit. The pin is only actuated when the activation temperature is reached, and at that point the area would not be tenable for building occupants or firefighters.

The tests used for fire door assemblies – UL10B, UL10C, and NFPA 252, do not require the doors to be operable at the conclusion of the test. Most locks and exit devices incorporate fusible links that render the hardware inoperable during the fire test, so the doors remain latched throughout the hose stream portion of the test. The auxiliary fire pin associated with less bottom rod fire exit hardware operates under the same principal. This is addressed in the NFPA 80 Handbook:

At some point during the fire, the latching hardware is designed to become fixed (e.g., unretractable), creating a positive latch that will secure the door leaves in the closed position to prevent the spread of deadly smoke, gases, and flames. All of the nationally recognized fire door tests require the fire door assembly test samples to be fully operable before the tests begin, but they specifically do not require fire door assemblies to be operable after exposure to a fire.

Another issue that has been raised is regarding firefighter access once the auxiliary fire pin has been projected after reaching the activating temperature. In addition to the fact that most latching hardware is designed to become inoperable during a fire, the doors themselves (especially steel doors) are likely to become wedged into the frame. The intumescent material required in some applications may also affect the operation of the door after a fire. Firefighter access will require a halligan bar, even if an auxiliary fire pin is not part of the assembly. And as one fire marshal commented, a door secured by a projected fire pin or inoperable hardware can be a warning to firefighters about the conditions on the other side of the door.

The I-Codes, NFPA codes, and NFPA 80 currently include language which clarifies that less bottom rod fire exit hardware is permitted on fire doors in a means of egress. For the I-Codes, this text was added in the 2009 edition, for NFPA 101 – Life Safety Code, the change was made in the 2012 edition, and similar language was added to the 2022 edition of NFPA 80. Here is where the requirements are currently found in each publication:

IBC-2021:

1010.2.4 Locks and latches. Locks and latches shall be permitted to prevent operation of doors where any of the following exist:

6. Fire doors after the minimum elevated temperature has disabled the unlatching mechanism in accordance with listed fire door test procedures.

Refer to the IBC for additional exceptions in this section.

NFPA 101-2021:

7.2.1.5.1 Door leaves shall be arranged to be opened readily from the egress side whenever the building is occupied.

7.2.1.5.5* The requirement of 7.2.1.5.1 shall not apply to door leaves of listed fire door assemblies after exposure to elevated temperature in accordance with the listing, based on laboratory fire test procedures.

A.7.2.1.5.5 Some fire door assemblies are listed for use with fire pins or fusible links that render the door leaf release inoperative upon exposure to elevated temperature during a fire. The door leaf release mechanism is made inoperative where conditions in the vicinity of the door opening become untenable for human occupancy, and such door opening no longer provides a viable egress path.

NFPA 80-2022:

6.4.4.3* Latching hardware shall be permitted to prevent operation of doors after exposure to elevated temperature in accordance with the listing, based on laboratory test procedures.

A.6.4.4.3 Some fire door assemblies are listed for use with fire pins or fusible links that render the door leaf release inoperative upon exposure to elevated temperature during a fire. The door leaf release mechanism is made inoperative where conditions in the vicinity of the door opening become untenable for human occupancy, and such door opening no longer provides a viable egress path. [101:A.7.2.1.5.5]

Before removing bottom rods and latches from existing fire exit hardware, it’s important to check with the manufacturers of the fire exit hardware and the fire doors, and to follow the required procedures. Doors that were installed before the introduction of LBR devices may not meet the fire test criteria for the use of the product. Retrofit kits are available for some brands of hardware, and the kit may include replacement top strikes that need to be installed, in addition to the auxiliary fire pin. Removing existing rods and latches without following the proper procedures could result in a fire door assembly that is no longer code-compliant.

The photos below show the auxiliary fire pin on the right, and the plastic cap over the hole in the other leaf on the left:

You need to login or register to bookmark/favorite this content.

The FD that serves my facility has absolutely no qualms about tearing open locked doors with a Halligan Tool when on a smoke investigation call, so I doubt they would hesitate to do the same to a door involved in an actual fire.

Chuck

Buy them a release tool

http://traditionstraining.com/panic-hardware-made-easy/

Lori

Great article

You can’t stress enough that when dealing with existing doors, you MUST confirm with the door manufacturer that they have successfully passed the fire test without bottom rods. This option has only been around for less than 15 years, and many doors are much older than that, and would not qualify for use LBR.