A couple of days ago, one of our specwriters asked about a closer on a door with rescue hardware, and another specwriter advised him to use a double-acting closer. I was surprised to learn that they weren’t aware of my FAVORITE LCN special template – ST-1895.

In order to explain this special template, I will first describe the use of rescue hardware. If you are already familiar with rescue hardware, skip the next two paragraphs.

Rescue hardware is used on inswinging bathroom doors in facilities where there’s a higher likelihood that someone might fall against the door inside the bathroom, preventing it from being opened to aid the person inside. These facilities include hospitals, nursing homes, and sometimes doctors’ offices. Under normal operation, the door opens into the bathroom, but if someone falls against the door and blocks it, rescue hardware allows the door to swing out of the bathroom.

Rescue hardware consists of double-acting pivots, a spring-loaded emergency stop that can be depressed to allow the door to swing out, and a double-lipped strike plate that extends all the way across the jamb depth of the frame. In some cases, the strike and emergency stop are combined into one product. A door with rescue hardware must be hung in a cased opening frame (a frame without a stop), and should have gasketing at the door edges to seal the gaps for privacy. You can find more information about rescue hardware here.

Rescue hardware consists of double-acting pivots, a spring-loaded emergency stop that can be depressed to allow the door to swing out, and a double-lipped strike plate that extends all the way across the jamb depth of the frame. In some cases, the strike and emergency stop are combined into one product. A door with rescue hardware must be hung in a cased opening frame (a frame without a stop), and should have gasketing at the door edges to seal the gaps for privacy. You can find more information about rescue hardware here.

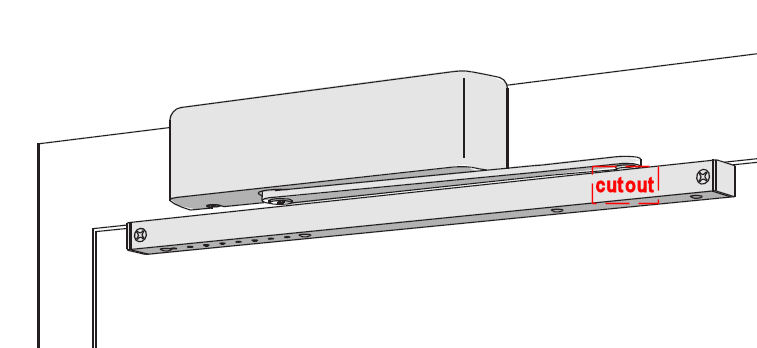

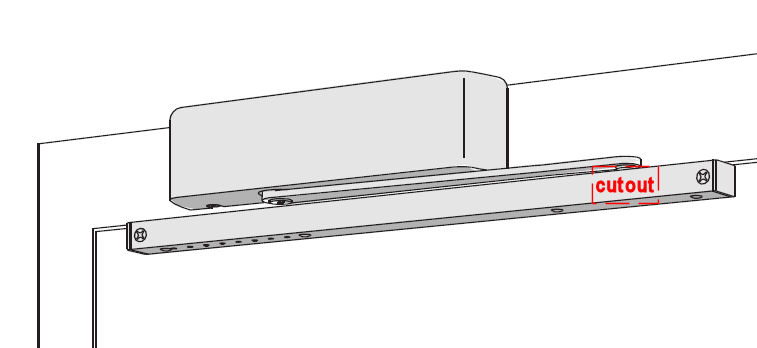

Since the door is typically inswinging but must become outswinging on occasion, a standard closer won’t work unless you do something funky like mount the closer on the corridor side and disconnect the arm every time you want to open the door in the emergency mode. Not a great idea but I’ve learned to never say “never.” You could use a double-acting concealed closer, but the 4020T x ST-1895 offers another option. The closer is mounted inside the bathroom, and the track has a small “window” cutout at the resting position of the roller. Under normal operation, the roller rolls back and forth on the inside face of the track closest to the door face. When the door needs to be opened out, the cutout allows the roller to disconnect from the track. When the door is closed again, the roller re-engages automatically.

What a concept!! What will those LCN engineers think of next?!

You need to login or register to bookmark/favorite this content.

But can it be used when a rated door is required???????

Rescue hardware wouldn’t be used on a door that needs to be fire-rated because the cased opening frame provides no barrier for the smoke.

So cool! Thanks, I never knew about that application before.

hey lori, pretty cool idea done by LCN engineers, to have track style closer with a cutout so people can be rescued when door has to be opened the opposite way. ill keep my eyes peeled for any of these rescue hardware closers from LCN now whats next???? hey, why not a closer that you can adjust by using a computer network or PLC’s on the valves or something of the like (so its easier to adjust the closer after installing, no need to be confused with what valve does what, or be really confused about that evil backcheck selector valve on LCN 4040’s also with this way, adjusting a closer is down to earth and to the point and installer knows what does what and no trips up and down a ladder between adjustments. (Norton door controls already makes something similar called the Norton TRINITY, but during initial setup I think it does involve manual adjusting with an allen wrench) I have had this idea in my head since I was about 12(when my interest in door closers started), but never made one self adjusting or computerized adjusting.

this way all they do is go onto a computer, type in some IP address of the network its connected on or maybe on an electrical port on the closer then adjust that way, when done disconnect.

hey, I never knew you had a FAVORITE template!! my favorite are those that use the EDA arm or H-CUSH parallel arm mounting on push side (both used on 4000 series closers) or the pocket closers that are in a wall recess when door is open (mounted on pull side with closer body on wall and track on door, usually seen in hospitals)

another great interesting post, I love reading about door hardware!

I need to study up on the ST templates a bit more. There are only about 4000 or so I’m not familiar with. This is one I’ll try to remember. I’ve had a time or two when I could have used it.

Lori…..I really needed this recently..too late… I will have to come to your site more often!

Is there an upcharge for this? If so what is it?

Thanks,

Hi Mike –

The list add is currently $150 to the price of the closer.

Well how about that! Almost nine years later and we finally got a spec that calls for ST-1895. They are using indicator deadlocks too so we don’t even need double lip strikes. It’s for a medical office building in Leominster, MA. Lori, did you have something to do with that?

Maybe they saw it on iDigHardware! 🙂

– Lori

Hello,

Does the door require a bullnose edge to be double acting?

Hi John –

It depends on how much clearance there is between the door and frame. I’ve seen this done both ways, but I think a bullnosed edge is more typical.

– Lori

As I was putting together that door order with this closer and modifying the pivot template to accommodate the edge gasketing, I got to thinking that no one seems to get too bothered by the quarter inch or larger gaps in typical bathroom stalls but spec writers and architects want to seal the edges of these doors, which when properly hung have around 1/16″ gap on the pivot side and about 1/8″ at the lock side. If you have a privacy set with a 1/2″ throw on the latch, there isn’t much left sticking in the strike when you under-size for a gasket that protrudes 1/4″ or more.

You’re right, but I for one am more comfortable with a gap in the bathroom stall vs. a gap in the bathroom door in the corridor of my doctor’s office. With that said, I’ve seen plenty of kids peering through the bathroom stall gap.

– Lori

To be double acting, need center hung pivots … but you would need to mount the pivots in an offset condition for this to work. Even then, the door would open into the frame – damage potential? Acrylic vinyl doors are expensive to replace … after trying to implement this template, I’m thinking I may stick with double acting closer.

Any insight on these concerns would be good as I know facility managers prefer surface mount closers over concealed.

Thanks.