Building codes have historically contained requirements for safety glass in and adjacent to doors, with an exception that allowed the use of traditional wired glass in fire-rated doors and frames. There was a time when traditional wired glass was the only option for fire-rated doors, but that is no longer the case. The 2003 Edition of the IBC limits the use of traditional (non-safety rated) wired glass to fire-rated doors and frames in locations other than Educational Occupancies. The 2006 Edition of the IBC does not mention wired glass or include the exception regarding its use in fire-rated doors, and requires all glass used in “hazardous locations” to meet the US Consumer Products Safety Commission CPSC 16 CFR, Part 1201. The 2006 Edition also requires safety glazing in hazardous locations to be marked with the manufacturer and safety standard it complies with.

Building codes have historically contained requirements for safety glass in and adjacent to doors, with an exception that allowed the use of traditional wired glass in fire-rated doors and frames. There was a time when traditional wired glass was the only option for fire-rated doors, but that is no longer the case. The 2003 Edition of the IBC limits the use of traditional (non-safety rated) wired glass to fire-rated doors and frames in locations other than Educational Occupancies. The 2006 Edition of the IBC does not mention wired glass or include the exception regarding its use in fire-rated doors, and requires all glass used in “hazardous locations” to meet the US Consumer Products Safety Commission CPSC 16 CFR, Part 1201. The 2006 Edition also requires safety glazing in hazardous locations to be marked with the manufacturer and safety standard it complies with.

Examples of hazardous locations include but are not limited to:

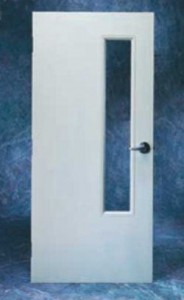

- Glazing in swinging doors except jalousies

- Glazing in fixed and sliding panels of sliding door assemblies

- Glazing in storm doors.

- Glazing in unframed swinging doors.

- Glazing in an individual fixed or operable panel adjacent to a door where the nearest exposed edge of the glazing is within a 24-inch arc of either vertical edge of the door in a closed position and where the bottom exposed edge of the glazing is less than 60 inches above the walking surface (the IBC includes some exceptions to this requirement).

- Glazing in an individual fixed or operable panel, other than in those locations described above, which meets all of the following conditions (the IBC includes some exceptions to this requirement):

• Exposed area of an individual pane greater than 9 square feet;

• Exposed bottom edge less than 18 inches above the floor;

• Exposed top edge greater than 36 inches above the floor; and

• One or more walking surface(s) within 36 inches horizontally of the plane of the glazing.

Exceptions for applications which are specifically noted as NOT being considered hazardous include the following:

- Openings in doors through which a 3-inch sphere is unable to pass

- Decorative glass

- Glazing materials used as curved glazed panels in revolving doors

- Commercial refrigerated cabinet glazed doors

- Glass-block panels.

- Louvered windows and jalousies

- Mirrors and other glass panels mounted or hung on a surface that provides a continuous backing support.

For more information, refer to IBC – 2003 and 2006, section 2406.

You need to login or register to bookmark/favorite this content.

My question has been about whether or not safety glass must be applied to interior doors. This area would be a half circle 7 inch radius at the top of the door. Waiting for my answer, I’m wondering if plexiglass could be alternate method eliminating the cost of safety glass.

Thank you

Hi Richard –

Per the International Building Code, the impact-resistance requirements do apply to interior doors, and would apply to a glass lite of that size. You would need to check your local code and look for a requirement for glass in doors to meet the US Consumer Products Safety Commission CPSC 16 CFR, Part 1201. If your code states that, the glass needs to be impact-resistant. The glass supplier should be able to confirm whether the glass meets that standard, and the newer codes actually require the glass to be marked with that information. I think plexiglass would also have to be impact-resistant.

– Lori

I work in a hospital in N.C. My question is: If fire doors w/wired glass was installed before 1987 is the glass exempt from being fire rated, UL listed, etc.? I’ve heard different theories but I can’t find any documentation to back it up.

Hi Gordon –

Unfortunately, the wording changed in NFPA 101-2012 in such a way that it does not clearly exempt existing glazing from the labeling requirements:

8.3.3.9 Existing installations of wired glass of 1/4 in. (6.3 mm) thickness and labeled for fire protection purposes shall be permitted to be used in approved opening protectives, provided that the maximum size specified by the listing is not exceeded.

I have spoken to NFPA staff about this, and it seems that the change was not intended to mean that all existing glazing required the label, but that’s what the code currently says.

– Lori