This post was published inDoors & Hardware

From a code and standard perspective, there are 3 basic types of automatic operators for swinging doors – Power Assist, Low Energy Power Operated, and Power Operated Pedestrian Doors – also known as Full Power Operated Doors.

- Power assist operators reduce the opening force so the door can be manually opened more easily, but they do not completely open the door without force applied manually. These operators are usually activated by pushing or pulling the door, although occasionally a wall-mounted actuator is used to reduce the force only for users who need that feature.

- Low energy operators are often used when the door will be opened manually by some users and automatically by others. The doors are subject to limitations on opening speed and force, to limit the generation of kinetic energy and the potential for injury, and they must be operated by a “knowing act” (read on). Because of these limits, most doors with low energy operators are not required to have safety sensors, control mats, or guide rails.

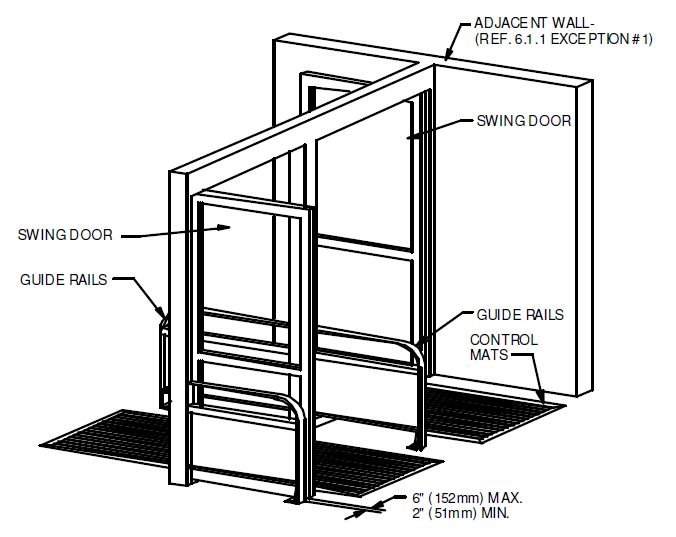

- Full power operators are typically found on high-use openings like the entrance to a grocery store or department store. They are not subject to the same restrictions on speed and force, and require safety sensors or control mats and guide rails to prevent the doors from opening if someone is in the path of the door swing.

ANSI/BHMA A156.19 – Power Assist & Low Energy Power Operated Doors is the standard that applies to power assist and low energy operators; ANSI/BHMA A156.10 – Standard for Power Operated Pedestrian Doors covers full power operators. Both of these standards are referenced by the International Building Code and other publications, so most of the detailed requirements are found in these standards rather than within the codes, but as a referenced standard the requirements effectively become part of the code.

The 2007 edition of ANSI/BHMA A156.19 introduced a requirement for power assist and low energy power operated doors to be activated by a “knowing act.” The knowing act method may be a push plate actuator or non-contact switch mounted on the wall or jamb, the act of manually pushing or pulling a door, or an access control device like a card reader, keypad, or keyswitch.

Prior to the 2019 edition, the standard also made recommendations regarding the mounting location of a knowing act switch including the following:

mounted within one to five feet from the door but not more than twelve feet

mounted within one to five feet from the door but not more than twelve feet- accessible from the swing side when the door is open

- not in a location where the user would be in the path of the moving door

- mounted so the user can see the door when activating the switch

- an installation height of 34 inches minimum and 48 inches maximum above the floor

In the 2019 edition of A156.19, the switch location became a requirement instead of a recommendation, and the location was modified slightly. The knowing-act switch:

- shall be installed within view of the door

- shall be installed between 34 inches and 48 inches above the floor, or as required by the local building codes

- shall remain accessible from the swing side of the door when it is opened

- shall not be located in a position where the user would be in the path of the moving door

- shall require the operator to have an additional time delay of 2 seconds per additional foot of distance from the door if the switch is located more than 7 feet from the center of the door

The 2010 ADA Standards for Accessible Design and ICC A117.1 – Accessible and Usable Buildings and Facilities also contain requirements pertaining to the actuators for automatic doors. Clear floor space for a wheelchair must be provided adjacent to the actuator, and beyond the arc of the door swing. The mounting height is variable, depending on the reach range associated with the location of the switch, but the range recommended by the ANSI/BHMA standards is acceptable for most applications. Actuators must not require tight grasping, pinching, or twisting of the wrist to operate, and the operating force is limited to 5 pounds maximum.

Stepping into the field of a motion sensor is not considered a knowing act. If automatic operation via a motion sensor is desired, automatic doors must comply with the standard for full power operators – ANSI/BHMA A156.10, instead of A156.19. This means that even though the door may have a low energy or power assist operator, it has to meet the same requirements as a full power operator, including the safety sensors or control mats and guide rails. Guide rails are required on the swing side of each door and are typically 30 inches high. For some locations, the need for guide rails may mean that motion sensor operation is not feasible. If certain criteria are met, walls may be used in place of guide rails. When doors are installed across a corridor, guide rails are not required if the distance between the wall and the door in the 90 degree open position does not exceed 10 inches.

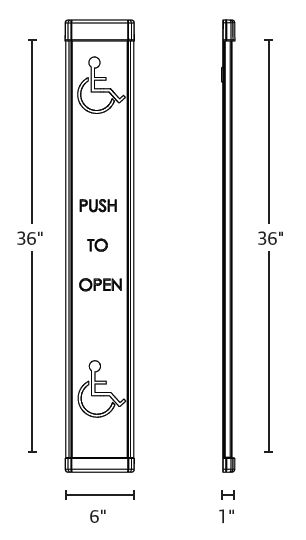

The California Building Code requires two push plate actuators at each actuator location – one mounted between 7 and 8 inches from the floor to the centerline, and the other mounted between 30 inches and 44 inches above the floor. Vertical actuation bars may be used in lieu of two separate actuators, with the bottom of the bar at 5 inches maximum above the floor and the top at 35 inches minimum above the floor. Actuators must be in a conspicuous location, with a level and clear ground space outside of the door swing. The minimum size for push plates is 4 inches, and the minimum operable portion for vertical actuation bars is 2 inches wide. Both types of actuators must display the International Symbol of Accessibility.

The California Building Code requires two push plate actuators at each actuator location – one mounted between 7 and 8 inches from the floor to the centerline, and the other mounted between 30 inches and 44 inches above the floor. Vertical actuation bars may be used in lieu of two separate actuators, with the bottom of the bar at 5 inches maximum above the floor and the top at 35 inches minimum above the floor. Actuators must be in a conspicuous location, with a level and clear ground space outside of the door swing. The minimum size for push plates is 4 inches, and the minimum operable portion for vertical actuation bars is 2 inches wide. Both types of actuators must display the International Symbol of Accessibility.

While all of these requirements have the same basic intent, it’s best to check your state and local code requirements to see which standard has been adopted, and what the specifics are in reference to actuators for automatic operators. Verify the actuator type/quantity, location, and any additional requirements. And keep in mind that additional safety features, including sensors and guide rails, may be required for low energy operators actuated by a motion sensor.

You need to login or register to bookmark/favorite this content.

If a touch less sensor has a 24″ read range would you consider that a unknowing act?

If yes what do you feel the max allowable read range should be?

Hi Brendan,

From ANSI A156.10 – 2011, Appendix E-5 (Not part of A156.10), so a recommendation only, not a code:

“Fixed non-contact switches should have a detection range no greater than 12″ to ensure a knowing act is utilized to activate the door”

Thanks for that answer, Ross!

Please send info. for the ADA vertical actuator, 36’Hx6″W:

1. Hard-wired wall mounted one.

2. Hard-wired weatherproof exterior on bollard (come with bollard), ie free standing.

Do you have 24 volt AC insted of DC switch?

Thank you for your quick response.

A low energy swing door opener is really of great benefits.Knowing its technical data is necessary.Thank you for your answer.

where can I find the code section that requires either two buttons or a vertical bar?

Hi Mark –

In the 2013 California Building Code, it is in section 11B-404.2.9 (c). I have only seen this requirement in the CBC.

– Lori

Hello,

I have an existing 1HR rated door in a 1HR smoke barrier wall. The users would like me to add hand wave sensors to activate the auto opener on the door, allowing easier access for people in wheelchairs.

Because this door needs to limit the transmission of smoke, do I need to tie the power for the operator and or the hand waves into the fire alarm so they loose power?

I am struggling to find this situation addressed in Building or Fire codes. I am in Ohio.

Thanks,

Marla

Hi Marla –

For fire doors, NFPA 80 requires the automatic operator to be deactivated upon fire alarm:

6.1.3.4 Power-Operated Fire Doors. Power-operated fire doors shall be equipped with a releasing device that shall automatically disconnect the power operator at the time of fire, allowing a self-closing or automatic device to close and latch the door regardless of power failure or manual operation.

– Lori

Perfect! This is what I was looking for.

Finally I fount recommendations regarding the mounting location. Thanks.

Lori,

Re: 11B-404.2.9 (c) The lower actuator pad requirement is a subset of the section above it that only deals with the 1 in 8 EXTERIOR condition. It is not a general requirement for all conditions. I don’t think it can be applied to just any condition. I have a well meaning hdw supplier that is insisting that it should apply to the inside of a toilet room door that is being voluntarily supplied with a low power operator, but otherwise meets all accessible criteria (5# pull, maneuvering room etc.) This is obviously a CA project, since this language only shows up in CA. Do you agree?

Hi Michael –

I know exactly what you mean about the requirement being a sub-set of the other requirement, but in my experience it is often interpreted as applicable to all automatic doors – not just the 1 in 8 exterior application. So technically you are right, but it’s all about how the AHJs are actually applying it. If it’s important to California to define the size and location of actuators, that they need the ADA symbol, etc., why would that only be important for the 1 in 8 exterior condition? Know what I mean?

I will ask my coworkers in California to weigh in.

– Lori

Hi Michael,

I know the code is written kind of confusing and it could be rewritten better. It states the 1 in 8 condition that needs an auto operated opening. The rest of the additional comments on that code talks about powered doors in terms of all powered (low-energy) doors where push plates are provided.

You are right that the code is written where it is debatable. In this situation where the hardware supplier is insisting that it only needs one 4″ min diameter actuator on each side of the door for a toilet room, I would have a local AHJ verify and approve that application to be sure.

In my case of specifying actuators for auto operators in California, I always do 2 actuators or one full length on each side of the door.