My next Decoded article addresses a recent study on clearances for fire door assemblies – the results of the testing may surprise you. Please share any input or questions before the article goes to print!

This post will be published in Door Security + Safety

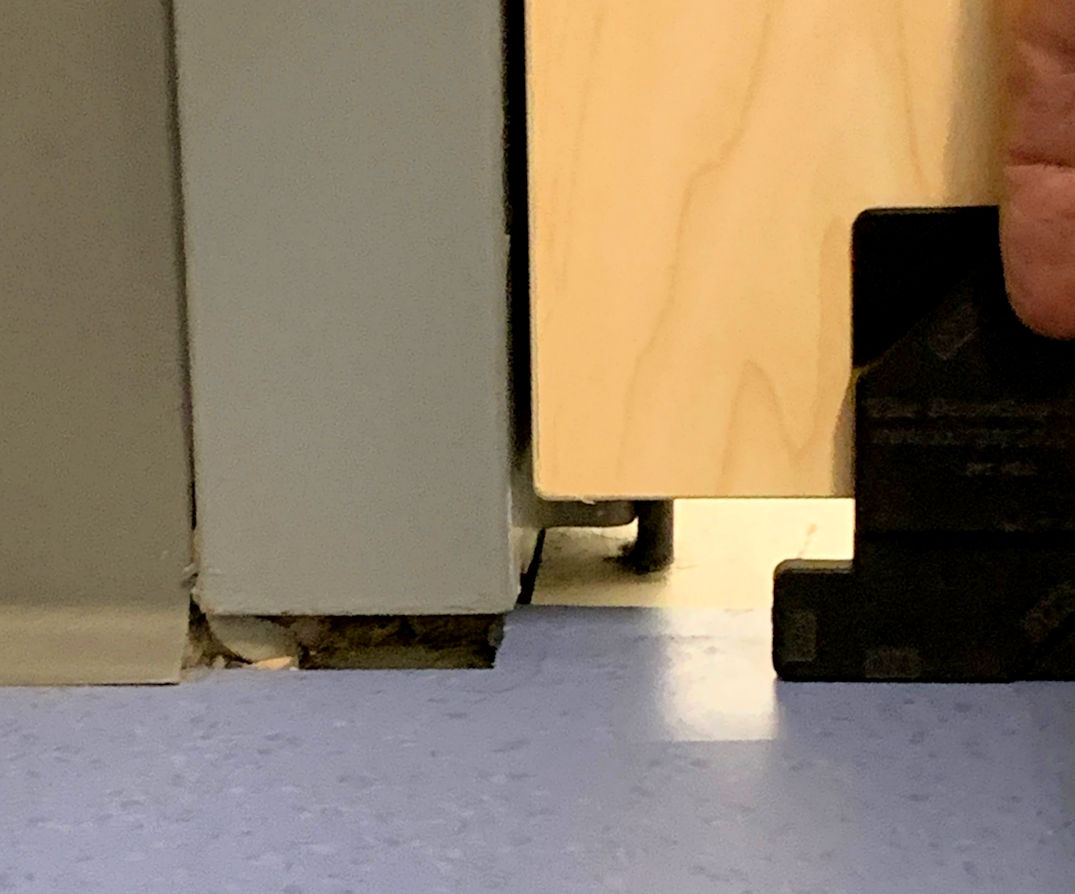

The clearance under this existing pair of fire doors varies from the jambs to the meeting stiles. Photo: Hal Kelton

Fire door assemblies, also known as opening protectives, are designed to protect openings in fire-resistance-rated walls to help compartmentalize a building and deter the spread of fire. These doors, frames, and hardware are required by current codes and referenced standards to be inspected after installation, after maintenance work, as well as annually. The inspection criteria for fire door assemblies can be found in Chapter 5 of NFPA 80 – Standard for Fire Doors and Other Opening Protectives.

Although the inspection requirements are not yet enforced in every jurisdiction across the U.S., health care facilities that receive funding from the Centers for Medicare and Medicaid Services (CMS) are required to conduct the annual inspections. Fire door assemblies in health care facilities play a critical role in the safety of patients and staff, giving them the option of sheltering in place during a fire rather than evacuating.

The Joint Commission and other accrediting organizations for health care facilities have been actively enforcing the inspection requirements in health care facilities with an initial deadline of January 1st, 2018. According to CMS rules, deficiencies found during the inspections must be resolved within 60 days or could put a facility’s accreditation at risk.

Clearance Requirements

Non-compliant clearances around fire doors are among the most common deficiencies found during these inspections. The balance between the limitations on fire door clearance and the ability of the door to function during daily use has been a constant challenge. Facility managers in health care occupancies and other buildings where fire door inspections are being conducted regularly have struggled with the time and resources needed to try to keep doors opening, closing, and latching properly while staying within the clearance limits of NFPA 80.

The most recent edition of the NFPA 80 standard (2022) mandates the following clearance limitations for fire door assemblies (measured on the pull side of the door):

- Clearance at the head, jambs, and meeting stiles of pairs:

- Hollow metal doors: 1⁄8 inch +/- 1⁄16 inch, maximum

- High-pressure decorative laminate (HPDL)-faced doors, 1⁄3-hour-rated flush wood doors, and stile and rail wood doors installed in hollow metal door frames: 1⁄8 inch +/- 1⁄16 inch, maximum

- HPDL-faced doors, flush wood doors, and stile and rail wood doors with fire ratings greater than 1⁄3 hour: 1⁄8 inch, maximum

- Door leaves constructed of other materials: 1⁄8 inch, maximum, unless otherwise permitted in the door, frame, and latching hardware manufacturers’ published listings

- Clearance at the bottom of the door:

- 3/4 inch, maximum, measured from the bottom of the door to the top of the finished floor or threshold

- 3/8 inch, maximum, or as specified by the manufacturer’s label service procedure, if the bottom of the door is located more than 38 inches above the finished floor (ex. access door or counter shutter)

- Where latches of the hardware project from the bottom of the door, clearance must be in accordance with the hardware manufacturer’s installation instructions – not to exceed 3⁄4 inch.

- Where a threshold is installed, clearance shall be in accordance with the hardware manufacturer’s installation instructions and listings.

Although it may be tempting to allow slightly larger clearances on fire door assemblies in the field, there is no way to know whether larger gaps could negatively affect the assembly’s ability to slow the spread of smoke and flames during a fire. Without the protection offered by code-compliant fire door assemblies, lives could be at risk.

When measuring the clearances on fire door assemblies, it’s important to use a gauge or tool that can accurately measure the gaps. Photo: Hal Kelton

New Research

Several years ago, plans for a research project on fire doors began; the hope was that new testing would demonstrate that larger clearances would not reduce the effectiveness of the fire door assemblies during a fire test – or during an actual structure fire. Because of uneven floors, the normal settling and shifting of buildings over time, and the natural expansion and movement of the doors themselves, many of the stakeholders involved hoped that the bottom clearance could be expanded from 3/4 inch to 1 inch or even slightly larger.

In May of this year, the findings of the study were published by the Fire Protection Research Foundation (FPRF); Fire Door Experimental Testing to Study the Influence of Door Gaps Around Swinging Fire Doors. The report documents 13 fire tests that were conducted on various fire door assemblies in single and pair configurations. Some of the assemblies had the code-compliant 3/4 inch clearance at the bottom, and others had 1 inch of clearance.

Of the 13 tests conducted, the doors in 12 tests did not meet the acceptance criteria of NFPA 252 – Standard Methods of Fire Tests of Door Assemblies. The doors that did pass the fire test were a pair of hollow metal doors with 3/4 inch of clearance at the bottom. The other configurations – with either 3/4 inch or 1 inch of clearance – did not pass the test. One concern that has been raised with the tests used in the research is that the doors did not include the intumescent material that is part of the standard construction of many wood doors today. It is unclear how this may have affected the performance of these doors during the tests.

In addition, the increased airflow through the larger clearances impacted the ability to maintain the required temperature in the test furnace. Even under lab conditions, the tests did not prove that fire doors that were compliant with current NFPA 80 requirements would function as intended, and other factors that could affect the performance of existing fire door assemblies in the field were not tested. The tests that were intended to provide answers, resulted in even more questions. Will fire doors tested to the current standards provide the needed level of protection in an actual fire? Should the test standards be revised? How can the tight tolerances be maintained while still allowing the doors to function?

Conclusion

The clearance under this fire door looks like it is in excess of 3/4 inch at the hinge jamb. Photo: Hal Kelton

Fire door clearance problems can be very tough to resolve in the field. Shimming hinges with steel shims or replacing hinges may help. There are edge guards, continuous hinges, and other products that are listed for use on fire doors where the clearance at the vertical edges exceeds what is allowed by NFPA 80. With such narrow tolerances of 1/8 inch or 3/16 inch at the head, jambs, and meeting stiles, complying with the clearance requirements while still allowing the door to open, close, and latch properly can be a difficult balance.

At the bottom of the door, adding a threshold may help to reduce the gap, but care must be taken to comply with the accessibility standards where applicable. There are door shoes and sweeps that have been specifically tested and listed for use at the bottom of the door where the clearance is greater than 3/4 inch, but be sure to check the limitations on door material, rating, and gap size. Standard door shoes and sweeps do not solve the clearance problem; the products must be listed for use on doors with excess clearance. Recent editions of NFPA 80 address these products by stating: “Products evaluated for fire doors with a bottom clearance in excess of 3⁄4 in. (19 mm) and listed for use at or under the bottom of the fire door shall be permitted where installed in accordance with their listings.”

One other way to avoid fire door issues is to help ensure that they are code-compliant from the beginning, by conducting the initial fire door inspection after installation as required by NFPA 80 (2013 edition and subsequent editions). This inspection should be included in the project specifications and will likely reduce future problems for the end user. Without the post-installation inspection, a facility manager may be faced with the responsibility for bring new assemblies into compliance with NFPA 80.

For detailed information on the FPRF research project, the complete report can be downloaded from NFPA.org.

Thank you to Hal Kelton of DOORDATA Solutions for the photos used in this article.

You need to login or register to bookmark/favorite this content.

On the ex AHJ side, I started using the door gap gauge,,, even though I was on the fire side of inspections,

http://doorgapgauge.com/how.htm

and would print out the tolerances and give them to the general contractor.

As you state get it right at least on the install.

My problem was sometimes the actual door was last thing to go in. The frame is set, walls finished, painted, and later doors added.

So here comes the pesky inspector with his handy dandy door gauge tool..

uh oh the door gaps are wrong. OK here comes trying to fix the gap issue,,, the contractor asks,,,, WHAT do we do?

Well I would like to say rip out the frame and start again.

Not sure what the answer is on how they should be installed, to avoid the gap issue????

Good questions. Here’s my thoughts…

Steel Door Institute has decent instructional videos in english and spanish. I recommend writing the project specs to require the GC to review these videos with the drywall and masonry door frame installers prior to installation. Pre-installation tutorials are standard in the specs for our projects. It’s always a safe bet to assume there’s a lack of sufficient education. It’s a reality of construction trades.

I have learned there’s not much point in complaining about the installation problems without trying to provide viable solutions.

English playlist:

https://www.youtube.com/watch?v=O69q6FHR99U&list=PLn2h_vp6a5Dq3NZgZ49b2ibGEdZ2UYKAG

Spanish playlist:

https://www.youtube.com/watch?v=dZZoiwG8pfU&list=PLn2h_vp6a5DpvE8L4nyywNrxBBpmg3m9Y

Aftermarket spreaders can help ensure the frames are set properly. I also show will show them how to check for square and out of plane issues with strings. I’ve been on the lookout for a precision laser capable of quickly checking door frames.

https://shop.justdoortoolz.com/product.sc?productId=107&categoryId=14

Between 50% to 80% of new rated openings fail my first inspection on new construction. This is mostly due to the door frame no being installed properly causing the excessive gaps around the door. When the gap exceeds the 3/4″ on the bottom they usually did not look at the drawing to see that the floor was flush concrete and expected either a threshold or some other type of flooring. I have not seen a new building pass a Fire Rated Opening inspection 100% yet. They are still trying to make corrections on buildings I inspected six years ago.

Fantastic ideas and resources

Hum Frame Spreader,,, seems in the line like a “” Code Stretcher”””

I wonder if increasing the stops from 5/8″ to 3/4″ would help solve perimeter clearance issues? Could allow for some additional margin on the hinge edge and head of pairs, while making the center margin within tolerance. We have had multiple projects where a frame was slightly large, but within manufacturers tolerance, and the doors were slightly small, but within manufacturers tolerance, resulting in the required gaps being impossible to achieve without adding so many gap solution products that the ADA requirements for maximum allowable opening force failed! All of this of course a fight of who was re$pon$ible, since all products met manufacturing tolerances, and the installer didn’t bid adding gap solution products when their frames were very accurately installed. The industry really needs to figure this one out!

How often do gaps around fire doors render them ineffective at blocking the spread of fire in cases where there are no flammable materials nearby? If the wall around a fire door were made of flammable material, a gap at the top of a fire door could allow flames to pass through and ignite the wall above. If, however, there are no flammable materials within a foot of a fire door, flames that pass through a door would be harmless.

Perhaps there should be separate classifications for fire doors which are suitable for use only when there are no flammable materials nearby, and those which would be suitable for preventing the spread of fire even to nearby flammable materials, the former category allowing broader gap tolerances.

Indeed, I wonder if a fire door which allowed some flames to show around the edges might in some cases be safer than one which behaved in “ideal” fashion. If a raging inferno on one side of the door is causing small flames to shoot out around the edges, that would serve as a rather effective warning that the door shouldn’t be opened. If, however, the unburned sign of the door showed no evidence of what was happening on the other side, someone who was unaware of the fire might try to open the door and then be unable to close it, instantly rendering it completely ineffective.

Fires create pressure

Also, the gaps will allow smoke to migrate

Plus the doors are there for a reason,,, normally part of a rated wall

Hello! You were such a lifesaver for sharing with us just how useful steel shims are in wedging our door hinges. A large section of my office building foundation has started to get a bit weaker based on my rough observation yesterday. Not only that, the emergency door at the basement parking is on the brink of getting detached too. I think some experts need to be employed to rectify the situation using the right equipment ASAP.