Within the same week, I received several questions about the timing for low-energy automatic operators…

Within the same week, I received several questions about the timing for low-energy automatic operators…

What is the required speed for the opening cycle of a low-energy automatic operator?

Is there a minimum closing speed?

How long should a low-energy automatic door stay open?

Are there any code requirements for sequential operation?

The answers to most of these questions are found in BHMA A156.19 – Standard for Power Assist and Low Energy Power Operated Doors. The model codes and accessibility standards do not include detailed requirements for automatic operators but require low-energy power-operated doors to comply with A156.19, so this standard includes a lot of important information that is needed for a code-compliant installation. If you don’t have a copy of A156.19, it can be purchased through BHMA’s website (if you’re an Allegion employee, you can download it from Techstreet).

In the standard, Table I includes the minimum opening time from backcheck to 80 degrees (whichever occurs first) and the minimum closing time from 90 degrees to latch check or 10 degrees (whichever occurs first). The opening and closing times in Table I range from 3 seconds to 5.5 seconds, and the minimum time depends on the door width as well as the door weight. For example, a 3-foot-wide door weighing 125 pounds must open to 80 degrees/backcheck in no less than 3.5 seconds, and close from 90 degrees to latch check/10 degrees in no less than 3.5 seconds.

Table II shows the total opening time to 90 degrees, which depends on the degree of opening where backcheck begins. For example, for backcheck at 70 degrees, the minimum opening time to 90 degrees is the opening time from Table I plus 1.5 seconds. The total minimum closing time is the applicable time from Table I plus 1.5 seconds (Section 4.4).

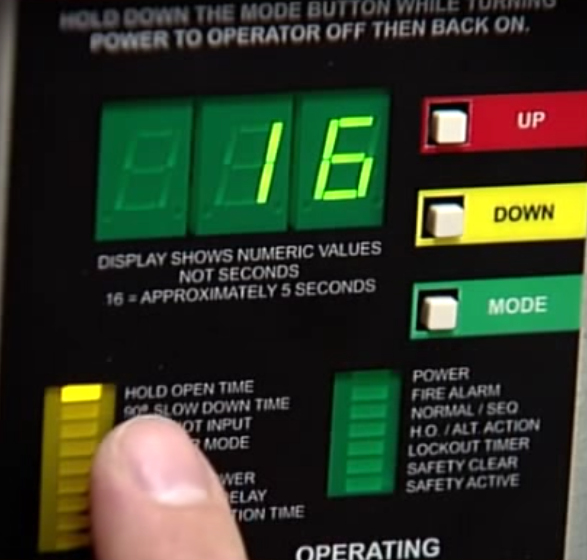

When powered open automatically (not opened manually), Section 4.3 requires the door to remain at the fully-open position for at least 5 seconds. The exception to that requirement is when the door is operated by a pushing or pulling motion rather than a wall-mounted actuator or other knowing act. With push-pull activation, the door must remain in the fully-open position for at least 3 seconds.

Given the original example of a 3-foot wide door weighing 125 pounds, with backcheck at 70 degrees, operated by a wall-mounted actuator, the total cycle time would be (3.5 seconds + 1.5 seconds = 5 seconds total opening time) + (5 seconds hold-open time) + (3.5 seconds +1.5 seconds = 5 seconds total closing time) for a grand total of 15 seconds.

There is one more thing in the standard about time delay – related to the position of the actuator. Appendix A includes supplementary recommendations, including the location of the actuators. The preferred location is within 1-5 feet of the door, and if located more than 12 feet from the center of the door, the appendix recommends adding a longer time delay to accommodate for the required time to travel from the switch to the door. The additional time delay should be a minimum of 1 second for each additional foot of distance (>12 feet).

Sequential operation describes a situation where there are two doors in sequence, usually in a vestibule, and operating one door with a knowing act operates the second door a few seconds later. With this application, building occupants do not have to stop in the vestibule to push another button before moving through the second door. I did not see any requirements or recommendations in A156.19 regarding sequential operation (correct me if I missed something), so each door would have to comply with the requirements for individual doors as described above, and the time delay between the initiation of the first and second doors would be dependent on the distance and speed at which building occupants travel.

For more information, consult A156.19, and if you have questions, you can leave them in the reply box.

You need to login or register to bookmark/favorite this content.

I like the Allegion Auto Equalizer because it is more infrequently used. These operators are slow, so they are less likely to be used as a lazy convenience. This is particularly true of doors secured by some form of electrical control. With the exception of those with disabilities, I need to get the door closed as soon as possible. These auto assist and standard operators take a considerable time to re-close, allowing more opportunity for piggybackers and tailgaters to enter the secured space.

You are correct, there are no requirements listed for sequential operation. Something we can tackle in the next revision of the Standard.

Thanks Len! I was hoping you’d weigh in! 🙂

– Lori

Only issue for any door that is installed as an Accessible door, no matter if it is a Manual Door closer or Energized, the same code applies, the door cannot have more than 15lbs of opening force and cannot close faster than 5 seconds from the 90 deg position to the latch point, they also must have a delay for the closing from the 90-degree position, this time delay is to be a minimum of 5 seconds from the time the door stops moving in the open direction, no matter the position of the door when it stops moving open. When I am sequencing doors, I follow the codes for both doors, and if needed provide a lock-out relay to prevent the second door from working if one door is open. This prevents piggybacking for security doors, and I also provide different timing for persons who require the accessible mode of the door from the security control system. This way you meet the requirements of the customers’ security requirements and accessibility codes.

I question the 15lbs of opening force, with an auto operator on an exterior door?

Hi Chris –

For manually-operated exterior doors, the IBC requires the maximum opening force to be 15 pounds to release the latch, 30 pounds to set the door in motion, and 15 pounds to open it to the fully-open position.

For automatic doors, the IBC allows 50 pounds instead of 30 to set the door in motion, BUT also requires doors with low-energy operators to comply with BHMA A156.19.

BHMA A156.19 requires low-energy doors to open with a maximum of 15 pounds to release the latch, 30 (not 50) pounds to set the door in motion, and 15 pounds to open it fully.

I hope that answers your question.

– Lori

Too many novice installers out there … my favorite saying If at first you don’t succeed… try looking in the waste basket for the instructions… Better yet get certified by spending a few bucks and take an AAADM COURSE . Most of the info you seek is in the product manual on set up . I would state anyone going into this type of field work get certified. Far too many HACK jobs out there