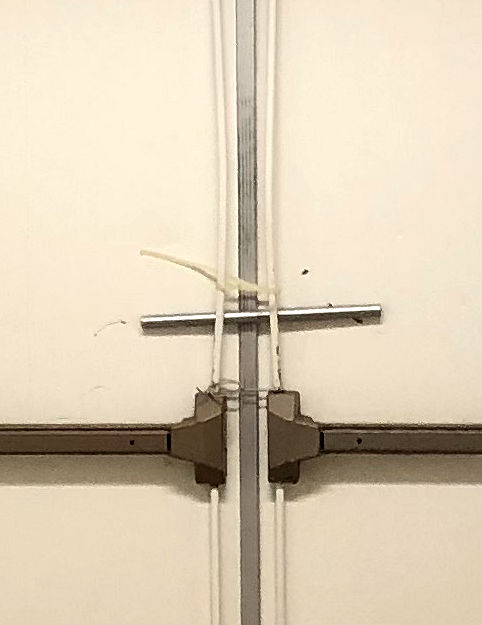

I have always specified removable mullions and rim panic hardware for exterior pairs instead of vertical rod panic hardware whenever possible. Some architects were not initially keen on the idea, but today’s Wordless Wednesday photos from Kelly Reese of Allegion illustrate what can happen to vertical rods over time. (I’m also wondering what happened to the closers.)

You need to login or register to bookmark/favorite this content.

You don’t need a closer if the door doesn’t open.

True! 😀

– Lori

Is it possible that this is in a closed-off part of the building, and maybe they’re tied shut like this because they are awaiting replacements? If not…they sure NEED replacements.

I couldn’t agree more, vertical rod devices are almost always problematic on exterior doors. I recommend single point devices and a key removable steel mullion where full width access may be needed at times. Mullions over 7′ tall should be equipped with two stabilizer sets per pair of doors to prevent flexing. I have removed numerous malfunctioning vertical rods over the years. My two cents.

Our school district is located on an island in a river delta and due to the nature of the soil vertical rod devices pose a huge maintenance issue. We have retrofitted mullions to well over 100 pairs of doors and specify them instead of vertical rods on all new projects. They have reduced repair work orders by a huge percentage and have made our buildings much more secure, in company with our card access/Lock Down system.

Our biggest issue with them is running electric strike wiring through removable mullions to enable staff to remove them for deliveries etc. We are installing QELA devices to avoid wiring in the mullions as an alternative but sure wish there were easily operable connectors available for locations where these expensive devices aren’t needed.

Hi Rich –

Thanks for sharing your insight! The Von Duprin KR4854 (KR9854 for fire doors) is prepped for a 299 strike and a 6111 electric strike, and there is a connector at the top for the strike wiring. It’s on page 37 of this catalog section: https://us.allegion.com/content/dam/allegion-us-2/web-documents-2/Catalog/Von_Duprin_Electrical_Security_Products_and_Accessories_Catalog_109981.pdf. Would that work?

– Lori

I totally agree Rich, we have now gone to QELA devices on all of our mullion applications as well as all of our outside doors even if they are singles. Also everything we do gets an EPT10 now even if the door is not electrified so that were are ready for an easy QEL conversion.

@Lori, the VD Mullion electrical connection is terrible its almost impossible to get your fingers in there and its way too easy to trap the wires in the mechanism. I am very dissapointed that Allegion has not re-engineered this product. I have in a few cases made a bracket and used the Rutherford 9505 ball contacts in areas where the mullions are taken out daily to move carts through. The allows the user to just remove and reinstall the mullion, it looks a bit odd with a bracket attached the mullion but it works great.

We also created a new mounting plate for areas where users need to remove the lower mount to get items through on a regualar basis as removing the anchor bolts loosens the anchor and causes the mount to loosen and fail.

Thanks Keith –

I’ll pass your comments along to engineering.

– Lori

I agree electric strikes in mullions is a huge pain in the butt. they are actually not removable once they are hooked up unless the strikes are equipped with molex ends to simply unplug and fish wires out the end. best bet is going with EPT to electrified exit device.

Hey Lori .I could not agree more . VR devices are constantly breaking down . I like you always spec a removeable mullion and add the appropriate hardware as required. Once installed I seldom if ever have to service the doors again

Where as I do agree that Rim to Rim exit devices are easier for installers and Maintenance, I do not agree that they are better for security or high traffic flow. Removable mullions loosen up over time allowing for extra play in openings which can cause false alarms when they doors are pulled on the the door position switch breaks contact. I have also seen doors with only a center mullion and rim exit devices pulled out at the bottom and then a student being able to reach through the opening and hit the push pad to open the door, This was a pair of 16ga still stiffened doors. I think the kid plays in the NFL now. Center mullions also get removed frequently when large items need to be moved through the opening and they also restrict the flow for large groups. Surface Vertical Rods can be damaged easily and violate ADA requirements at some locations. Some concealed vertical rods are difficult to adjust, but if installed properly and if the maintenance personnel are properly trained, they should be able to maintain the doors. I prefer the concealed vertical cables, but then again they must be installed and maintained properly. The single point adjustment makes this easier than most systems. Since I am on a college campus we have thousands of students passing through openings at any give time during the day, The larger the opening, the less of a bottleneck we will have as students leave and enter the buildings. The two point locking keeps the openings secure when the buildings are locked down and electrified hardware with RX and QEL connected through a power transfer makes for very clean appearance at the openings and a direct single pathway for installation and troubleshooting any issues. Concealed Cables have no ADA restrictions and the latches are strong enough to prevent unauthorized access.

Totally agree!! The only way to go for long term durability!!

We have taken to using these connectors for removable mullions. They only go in one way, install easy, and custodians rarely forget to plug these back in.

https://www.homedepot.com/p/Ideal-102-Model-PowerPlug-Luminaire-Disconnect-25-Pack-30-372/303741498

Thanks Ben!

– Lori