In 2017, a fire at Grenfell Tower – a high-rise apartment building in West London – resulted in 72 fatalities and 70 people injured. During the inquires that followed, investigators found that the fire door assemblies leading from the corridors to each apartment did not perform as they were intended. Instead of delaying the spread of fire for 30 minutes as required by the adopted codes, the assemblies failed after approximately 15 minutes.

Fire doors have been under increased scrutiny in the US as well. The requirements for annual fire door assembly inspection are being enforced in all health care facilities that receive Medicare or Medicaid funding. Some fire marshals are enforcing the requirements in other types of facilities in their jurisdiction. Finally, more than 10 years after the inspection requirements were added to NFPA 80 – Standard for Fire Doors and Other Opening Protectives, the deficiencies that could impair the performance of fire door assemblies are being addressed.

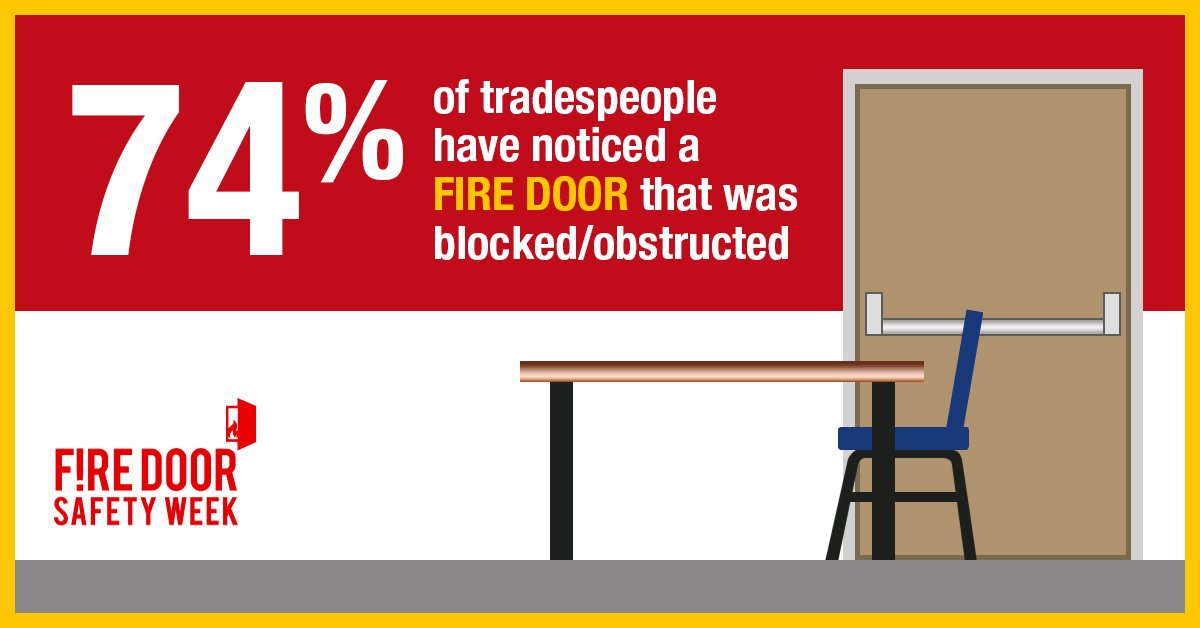

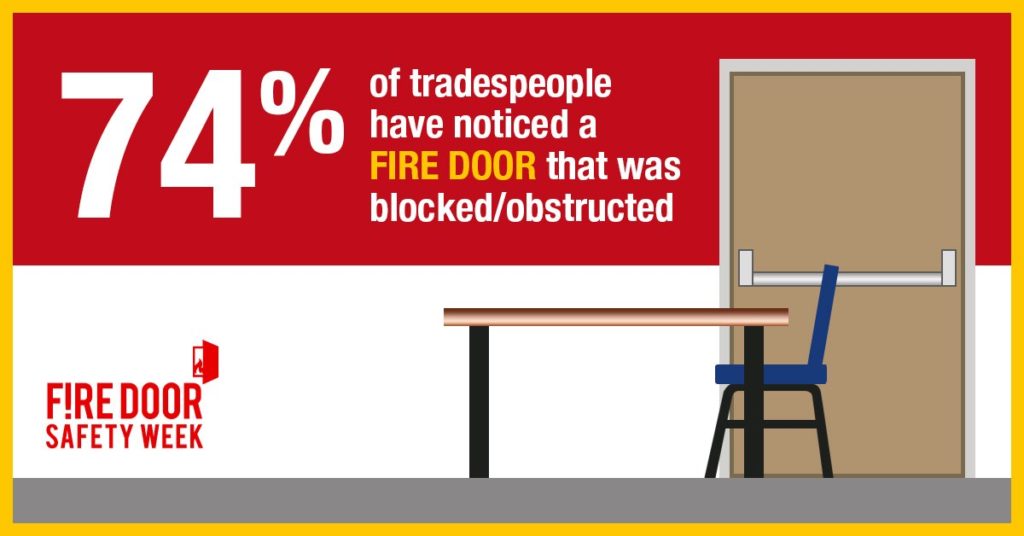

Each year since 2012, the British Woodworking Federation has held a Fire Door Safety Week, to raise awareness about the role fire doors play in a passive fire protection system, and to encourage people to examine fire doors and report problems. The most recent Fire Door Safety Week was held September 24-30. As part of this effort, dozens of educational resources have been created and are available through the Fire Door Safety Week website.

The fire door requirements in the US and the UK differ, but the performance of fire door assemblies is just as crucial regardless of where they are located in the world. I think it’s about time for the US to ramp up education on fire doors and increase the safety of our buildings. We have seen fire door failures in multi-family residential buildings in the US that resulted in fatalities and injuries as well as property loss. We have also seen how properly-installed fire door assemblies can help deter the spread of fire. So what are we waiting for? Let’s get the general public up to speed, in addition to educating fire marshals, end users, architects, members of the door and hardware industry, and others who are involved with the technical aspects of fire door assemblies.

My question for you – especially those of you who are actively involved in specifying, supplying, and/or inspecting fire door assemblies, is this: What resources and materials do we need?

WWYD?

Here is one of the videos produced by the BWF Certifire Fire Door Scheme, which shows why correct specification and installation are so important. Check out the Fire Door Safety Week website for other resources.

You need to login or register to bookmark/favorite this content.

I hate the terms

Fire door, except in construction context

Emergency exit

Fire exit

ETC

Yes maintains and closing fire rated doors or doors, to slow the spread of fire,,

Needs to be put out there for the public to know and understand

If it is an exit call it that

I agree Charles – a lot of people say fire doors when they’re really talking about egress doors.

– Lori

A simple Fire Door 101 video that can be shared by people in the industry on social media and hopefully get to the general public to explain what a fire door is and what it does. I would love to think it would be a PSA that would run on TV, but I think that is just me dreaming.

I’ve got that on my list – thanks Jody!

– Lori

Lori,as I have mentioned to you before,the way specifications are now written ,as to imply intent only, do not know for sure what I need ( you figure it out ) its your responsibility supply the proper hardware and meet all the codes .As long as specifications are written this way they are going to be problems . With the liability of safety and peoples lives at risk, there should be a demand for a complete, clear , and concise specification properly covering the opening as to the requirements.I think this is where you separate a Consultant from someone just selling hardware. Tim Gottwalt had a great article in the CSI Specifier of Feburary 2018 as to the responsibility of the specifier.

Thanks Bob –

When I was writing hardware specs I wrote fairly detailed hardware schedules that included the required components to function correctly and to be code-compliant. Of course I screwed up a few times – it’s easier for the specwriter to avoid making mistakes when the specs are less detailed, but I’ve never been a fan of the vague specs that leave it to someone else to figure out.

– Lori

Better educated inspectors and fire marshals, they tend to be a bit clueless regarding doors and hardware.

I wonder how to best reach people who need more education on doors and hardware. Any ideas? I am always touched when an AHJ asks me for help with an interpretation. That was very rare 10 years ago, and even moreso 30 years ago.

– Lori

New age hardware for old school inspectors…

That could be the class title and part of their continuing education.

Hah – nice!

– Lori