After almost 10 years of writing daily blog posts on code requirements related to doors and hardware, it always surprises me when a question comes along that I’ve never thought about:

After almost 10 years of writing daily blog posts on code requirements related to doors and hardware, it always surprises me when a question comes along that I’ve never thought about:

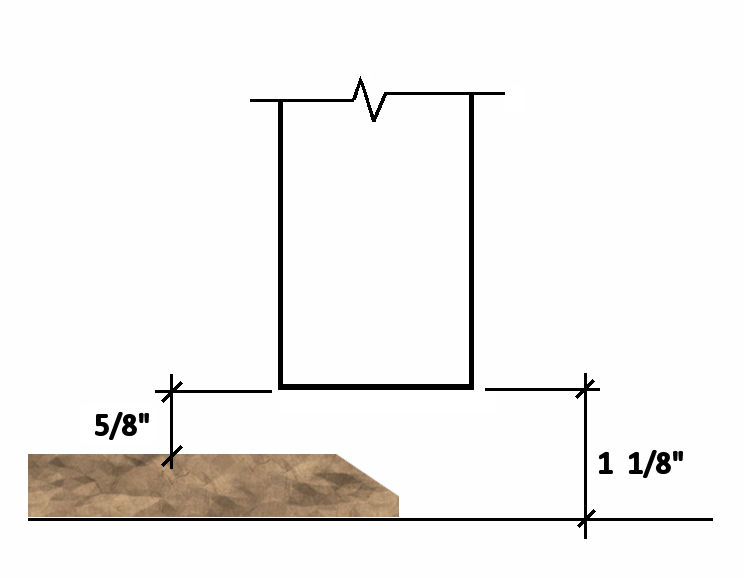

How do you measure the clearance at the bottom of a door when the clearance varies between the push side and the pull side?

I’m sure this is not an uncommon situation, but I could not find a definitive answer. NFPA 80 limits the clearance at the bottom of a fire door to 3/4-inch.* In addition, NFPA 101 limits the clearance at non-fire-rated corridor doors in health care facilities to 1 inch. So is the clearance shown in this drawing acceptable for either of those applications?

I checked with NFPA staff, and they confirmed that the location of the measurement is not addressed by NFPA 80. NFPA’s advice was to coordinate with the Authority Having Jurisdiction (AHJ) regarding where the measurement should be taken.

Do you have experience with this? Where did the AHJ require the clearance to be measured?

WWYD?

* When the bottom of the door is more than 38 inches above the floor – like a chute door – NFPA 80 limits the clearance at the bottom to 3/8-inch.

~~~

Related Posts:

You need to login or register to bookmark/favorite this content.

I would deal with the fire door requirement first the looks issue second, the door was probably not tested with the shown arrangement.

From my experience, standard undercut of manufactured hollow metal and wood doors is 5/8 to 3/4 inch from bottom of frame. Clearance is defined as the dimension from the bottom of the door to the bottom of the floor finish material. Go to https://www.dhi.org/shared/forms/PDFforms/Publications/TechTipJuly07.pdf

Years ago I had a customer with an issue where there was a dip in the the floor at the middle of a double fire rated opening with 5/8″ undercut at the jambs and a 1″ undercut in the middle. The AHJ issued a violation because of the excess undercut in the middle. If any undercut was exceeded then the opening was in violation. The solution we used was to just install automatic door bottoms on each leaf and that fixed the problem.

Interesting question. If the condition you’ve illustrated does not otherwise require under-the-door air make-up, I’d have to interpret conservatively and say that the 1-1/8″ measurement is definitive, and go with a concealed bottom seal. If we need air make-up (gap appears to be too narrow for that in this case, though), then I think we’re looking at extending the threshold.

Most every authority I encountered used a fairly unchanging version of NFPA 80.

1/8th inch gap door to frame.

3/8th inch clearance door bottom and noncombustible sills

3/4 inch door bottom and floors without sills

5/8 inch door bottom and rigid floor tile

1/2 inch clearance door bottom and floor coverings like carpet

It was emphasized that clearance

requirements could only be expected to limit smoke quanity.

The most pesky problems I encounter were floors not being level, poorly anchored frames and loose hardware. I used to think floor clearance was not so important because all the fire gases I encountered were buoyed upward until the day that a hospital staff member set a tray of medications on a energized burner. When I arrived it looked like a white waterfall sinking to the floor and flowing away from the burner top, under the door and out into the corridor. The smell was hard to describe – probably lots of toxic chlorine containing compounds

Clearances on sides, meeting edges of pairs, and head are all supposed to be measured from the pull side. Perhaps the next code edition could be edited to clarify from which side an undercut is to be measured, how to allow for unevenness (this commonly occurs on the sides and head as well), and how to allow for varying floor heights, floor finishes, or thresholds as in this example.

When I was serving as an AHJ I always instructed our staff to consider the minimum and maximum gap or undercut to determine the average. If the average was equal to or less than what the Code allowed I would accept it.

If the maximum gap and undercut around a door is calculated it will equate to “X” square inches, depending upon door height and width. Since doors can be of varying widths and heights the allowance for gaps and undercuts really are arbitrary because different size doors will allow different quantities of smoke to pass across the same barrier. IMO, it does not matter if the area of the undercut is a perfect rectangle, a triangle, or some other irregular shape provided the total area of the gap does not exceed that which is allowed by the rectangular area. FWIW, for the threshold in question I would measure it from the smaller side because that is still the smallest opening the smoke must pass through regardless the direction of flow and I believe this is consistent with the approach to measure the leading edge gap of a beveled door from the pull side which is the narrowest side of the bevel.

Thanks Larry!

– Lori