I occasionally publish a post from a guest blogger – if you have a post you’d like to share, drop me an email. Today’s post is from David Gloriso of Allegion. I’d love to hear your opinion on this issue…are electromagnetically-locked doors with door-hardware release safe as currently addressed by the model codes? Or should additional safety measures by required? For more information about the requirements for doors with electromagnetic locks, refer to this Decoded article.

~~~

Specifying door hardware is a complex process. Is everything compliant with all applicable codes? How do you balance safety and security with convenience and efficiency? With electronic to mechanical options, door hardware is not a one-size-fits-all solution. So it’s important to understand when and where certain types of hardware should and shouldn’t be used.

For example, when selecting an electrified locking device for a specific application, a consultant should exhaust all electromechanical options before specifying electromagnetic locks. Why? Because of the inherent nature of an electromagnetic lock. Caution, therefore, is required before proceeding with this locking solution. This is especially true with respect to assembly and educational occupancy groups. In my opinion, electromagnetic locks should never be specified on egress doors in these two occupancies — especially on doors requiring panic hardware.

Why? Let’s take a look at how this product operates. An electromagnetic lock is essentially a large electromagnet in a rectangular housing that is mounted on the door frame and a steel armature mounted on the door. These products use electromagnetism to control the entire locking mechanism. When power is applied to the locking device, an electromagnetic force bonds the armature and lock together, securing the opening with more than 1,500 pounds of holding force. An electric switch is the only means by which access or egress is accomplished.

Why? Let’s take a look at how this product operates. An electromagnetic lock is essentially a large electromagnet in a rectangular housing that is mounted on the door frame and a steel armature mounted on the door. These products use electromagnetism to control the entire locking mechanism. When power is applied to the locking device, an electromagnetic force bonds the armature and lock together, securing the opening with more than 1,500 pounds of holding force. An electric switch is the only means by which access or egress is accomplished.

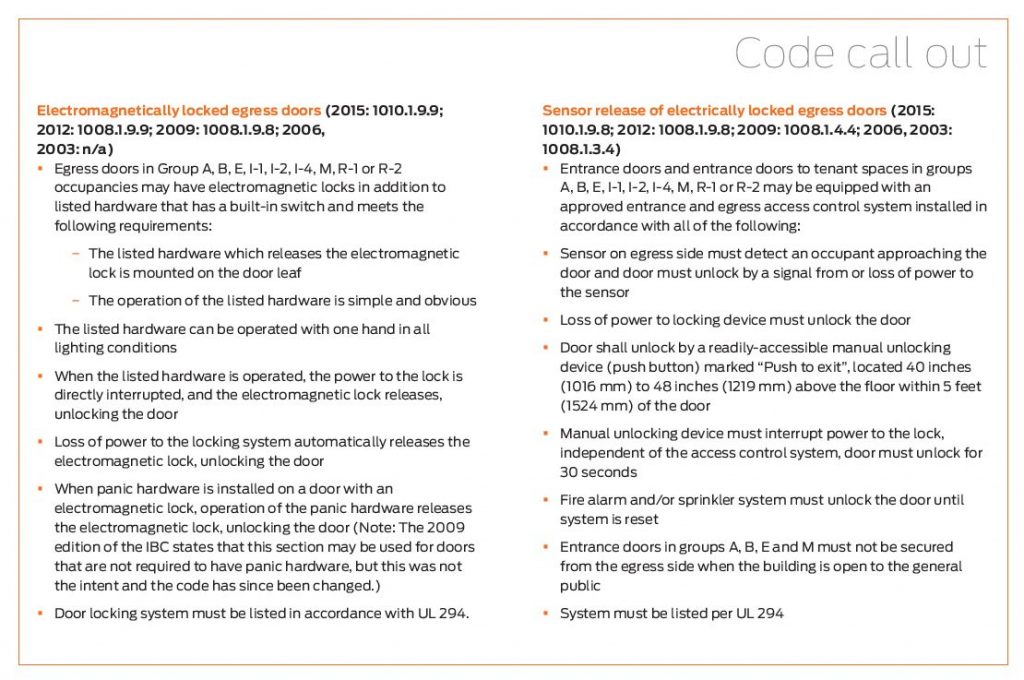

This seems secure, right? It is. It’s very secure, in fact. But is it safe? In my opinion, not when it’s installed as currently allowed by the model codes – with door-mounted hardware to release the lock, and without a secondary switch or connection to a fire alarm or sprinkler system. According to the International Building Code (IBC) and NFPA 101 – The Life Safety Code, if the electromagnetic lock is released by door-mounted hardware, the lock must be unlocked by a switch in the panic hardware, sensor bar or lever handle, and also by loss of power. This could potentially put the building’s occupants at risk should the switch fail during an emergency.

There is a separate section of the model codes that addresses electromagnetic locks released by a sensor detecting an approaching occupant, instead of releasing the electromagnetic lock with door-mounted hardware. For this application, the model codes require two additional safety features In addition to the sensor, the lock must also be released by activation of the fire protection or detection system and by an emergency override button beside the door. I believe that these additional release methods should also be required for electromagnetic locks released by door-mounted hardware.

Evolution of changes

Prior to the 2009 editions of the IBC and NFPA 101, these codes only addressed the use of a sensor to unlock an electromagnetic lock, and did not include the section that applies to electromagnetic locks released by door-mounted hardware. The original section required a primary sensor switch that would detect a person as he or she approached and unlock the door to allow egress. The lock was required to unlock immediately upon loss of power, so battery backup was not allowed. It also had to connect to an approved fire alarm or sprinkler system and required a secondary switch mounted on the wall as a backup means to release the magnet. Specification of electromagnetic locks can be more difficult than specifying other products, as the specifier has to coordinate with multiple systems to ensure that the door will allow code-compliant egress.

In the 2009 edition, the IBC and NFPA 101 introduced new sections which permit electromagnetic locks to be released by a switch in the door-mounted hardware, without some of the release methods required for electromagnetic locks released by a sensor. For the door-hardware-release application, the new model code language did not mandate the secondary switch, and didn’t require the device to be connected to a fire alarm or sprinkler system. These are my two biggest concerns with the 2009 changes. The IBC did, however, state that electromagnetic locks could not be used on assembly or educational occupancies where panic hardware or fire exit hardware was required. But this limitation was removed in the 2012 edition as long as the panic hardware would release the electromagnetic lock.

The reason I believe it was a mistake to omit the backup connections to a secondary switch and fire alarm system is because these devices are unlike other hardware components — electrified or mechanical. With an electromechanical device, there is always a mechanical means to release the latch. But with electromagnetic locks, there is no mechanical means to release the magnetic force that is locking the door. I imagine this is why the model codes included such rigorous requirements in the past. So, I was alarmed to find that the 2012 and 2015 editions of the model codes not only continued with this language, but also permitted these systems to be used on openings in assembly and educational occupancies where panic or fire exit hardware is required.

Concerns

The 2015 editions of the IBC and NFPA 101 are the most current version available, so these practices are acceptable by the code. But I advise architects, specification consultants and others in our industry to consider the concerns before choosing an electromagnetic lock to secure an egress door.

Electromagnetic locks are fail-safe in that the door will be unlocked if there is a loss of power. But what happens if the switch fails, unrelated to a power outage? Electromagnetic locks are designed to be incredibly secure and strong, using 1,500 pounds or more of holding force between the magnet and armature. However, it’s that same force that could impede egress in the event a switch fails, which can happen.

If there is an emergency in an assembly or educational facility, the occupants rely on panic hardware on egress doors to allow them an easy way out of the building. What happens if the switch in the panic hardware fails to release the electromagnetic lock in a panic situation? There is now nearly a ton of holding force keeping that door closed with no mechanical means to override the magnetic holding force. Pushing on the panic hardware will release the latchbolt, but the switch inside has failed, leaving it unable to release the holding power of the magnet. And it’s not connected to a fire alarm or sprinkler system because the code doesn’t require it. In addition to that, there is no secondary switch because, again, the code doesn’t require one.

I wouldn’t want to be in a building where safety was reliant upon a single switch controlling an opening with an electromagnetic lock on it. While Allegion rigorously tests the switches that are used inside its panic hardware and latchsets to release the magnetic force, that’s not mandated across the industry. The cycle requirements for these locking systems are set forth by UL 294 and other industry standards, which do not require the same rigorous testing as the standards for panic hardware. So why would we let the safety of future building occupants rely on a switch without a backup means of unlocking the door? And why would we allow it in assembly and educational facilities?

Solutions that go above and beyond for safety

The best practices are what many architects are already doing on a daily basis. If a project has an opening where panic hardware is required on the push side and the client wants a card reader on the pull side, there are other solutions that can deliver the same functionality.

Electric latch retraction panic hardware. On the pull side, you present a credential and it sends power to the panic hardware, which retracts the latchbolt so you can open the door. From the push side, you don’t have to worry about the holding force of an electromagnetic lock, you don’t have to worry about whether the switch fails. You just use the push pad to open the door, which should require no more than 15 pounds of force.

Panic hardware with electrified trim. When you present your credential on the pull side it unlocks the lever handle, allowing you to operate the lever handle and open the door. Again, on the push side there is no need to worry about any electronics; simply push on the panic hardware and go.

Electric strike. An electric strike can also be used in conjunction with panic hardware. The swipe of a credential energizes the electric strike, allowing you to pull the door open. If you’re leaving, it’s as easy as pushing on the panic hardware.

Electric strikes are also a viable option for openings on which panic hardware is not required. In these instances, a storeroom function lock is usually specified to ensure that the electric strike is the primary means of unlocking the door. Once again, the lever-handle on the inside is always unlocked to allow free egress at all times. It’s a mere mechanical operation performed by an occupant and is not reliant upon any internal switch.

Electrified Lock. Another electromechanical option available for openings that are not required to have panic hardware is an electrified lock. Available in both cylindrical and mortise lock platforms, the electrified lock provides the same functionality one would get from an electric strike. The only difference being that the lever-handle on the locked side of the opening is the part which is electrically controlled. When a signal is received to unlock the opening, the lever-handle is unlocked to allow the authorized individual to enter. Yet, as with the other electromechanical options, the lever on the inside of the opening is always unlocked to allow building occupants to freely egress at all times.

I believe that electromagnetic locks can be beneficial in some applications as a last resort — when all other means have been exhausted. For example, an all-glass door with no metal vertical stiles in a commercial office building would prevent the use of an electrified lockset or electric strike. In these instances, I may recommend electromagnetic locks if panic hardware is not required, but only if the electromagnetic locks are released by primary and secondary switches and are released by the fire alarm or sprinkler system. Ultimately, I follow the pre-2009 model code requirements.

Occasionally hospitals have pairs of double egress doors that need to be locked. Because they are double egress and require panic hardware, securing the opening requires an electromagnetic lock. A card reader is usually what controls the locking and unlocking of such openings. Unfortunately, you cannot use a secondary switch for these applications, but I still make sure that it’s tied to the fire alarm system. In addition, a hospital is a 24/7 facility with trained personnel available at all times. Hospitals are also considered “defend-in-place” facilities, since many of the occupants are incapable of self-preservation. This fact mitigates much of my concern normally associated with electromagnetic lock applications.

The goal is to provide the safest possible environment for the building owner and future occupants, while maintaining the appropriate level of security and convenience. I sincerely hope it doesn’t happen, but I could see an instance where there could be a loss of life because of the way the language is written in the current codes. I hope others will join me in going beyond the current code requirements to ensure safe and secure environments — ones that leave no room for doubt in the event of an emergency.

David S. Glorioso, AHC, is a thirty-three year veteran of the door and hardware industry. He is an architectural consultant at Allegion, previously Ingersoll Rand Architectural Hardware. During his tenure, David has worked in various markets for the company, including Florida, Michigan, Indiana and Ohio. While he has fulfilled various roles within the company over the years, most of his time has been spent developing relationships with the architectural community and assisting the various firms in developing the hardware specifications for their respective projects.

You need to login or register to bookmark/favorite this content.

Very well thought out.

I have felt that there seems to be to many different set ups in the IBC for door release.

Not sure why they cannot be condensed down to one or two???

I had wrestled for a long time, why electronic touch bars could not be used in place of panic hardware? This article along with very good guidance from Lori, backs up why I got away from that thinking.

Yes modern technology is great, but does it meet the intent of the code?

David thank you again for a great article

I would much rather see electrified E option trim used on that panic bar than a maglock.

Otherwise the maglock should be delayed egress with a fire alarm release

In my design practice, I avoid electromagnetic locks at all costs.

Many years ago Mag Locks had been installed on the entrance/exit to a Neonatal Intensive Care Unit (NICU).

Working for a large security integrator at the time, we received an emergency call from the hospital that the door would not unlock either by credential for ingress or exit device/sensor for egress.

All hands on deck we found that the only way to release the door was to kill the power supply in the electrical room.

Post almost a disaster, we found a short in the door frame had created a ground loop that permanently powered the Mag lock.

One in a million but good enough for me to rip out the Mag Lock.

New electrified exit devices were installed that afternoon.

We have lots of them, but we don’t like them. The ones that we still have are all totally fail safe. All switches, wire loops, electric hinges, wire runs must be intact for the door to be locked. If any component fails, the door unlocks. These doors are controlled by a card access system and are a major pain. Some of the doors have switches in the bars. Others have touch/sense type bars and even those tend to unlock the door if the circuit board fails. We have one building with optical bars that have redundant beams across the front of the bar. A spider can leave that building unlocked. We don’t dislike them because of safety, but because they are less secure than mechanical devices. Any failure leaves the building wide open. We probably get a dozen calls a year after hours for an unsecured door.

I think Glorioso left out an other and much more likely possible failure: A short in the wiring from the switch, which should be normally closed. So if the wire transfer device from the frame to the door, which moves every time the door is cycled, fails with the two conductors touching each other, then the switch has no effect even if it is working correctly.

Good point Zeke!

– Lori

I’m with David. Most of the time there are many other safer, simpler and more secure options.

Lori, I was at a local school recently and doing lock work. When I was ready to leave by the way of the main entrance, as I would I pushed on the panic hardware and the door did not open. I was aware that these doors had mag locks and I had to push a switch on the wall next to the door to get out I was somewhat alarmed with this setup. I do not think we should have these mag locks on these doors.

Hi Leon –

While mag-locks are not prohibited by the model codes in educational occupancies, it’s not acceptable to have only the auxiliary push button as a release device. If I was using a mag-lock in a school I would use the door-mounted hardware to release the mag-lock, to prevent someone from accidentally unlocking the lock by approaching the door to see who is there. When a mag-lock has an auxiliary push button release, the lock is also supposed to be released by a sensor detecting an approaching occupant, by activation of the fire alarm, and by loss of power.

– Lori

It was my understanding (maybe incorrectly so) that the two code sections were to be used together. The paragraph that describes the requirements for the switching built into the panic device was simply to describe and allow that as an option to the motion sensor, and that the balance of the safety items (connection to the fire alarm and emergency egress button) were still required as stated in the original paragraph. I would be interested to hear from a knowledgeable source, like Lori, as to whether that assumption is correct. In the mean time, I operate under that assumption and make sure to include those items any time I find that I’m faced with a maglock on an egress door.

Hi Rex –

The two sections are not intended to be applied to the same application. The IBC Commentary attempts to clarify that…

Under Section 1010.1.9.8 Sensor release of electrically locked egress doors, the Commentary says: “The intent of this section is to provide consistent requirements where an electronically locked door is unlocked by activating devices mounted somewhere other than on the door itself. The unlocking activation is designed to be from a passive action by the occupant (e.g., walking to the door triggering a sensor), but the system includes a required nearby manual unlocking device (such as a push button) as a secondary electrical lock release device.”

Under Section 1010.1.9.9 Electromagnetically locked egress doors, the Commentary says: “The intent of this section is to provide consistent requirements where an electromagnetic lock is released by door-mounted hardware such as a panic bar, lockset/latchset, or touch-sense bar, all of which would be equipped with an integral switch that, when actuated by the normal actions of opening the door, causes the electromagnetic lock to release allowing immediate egress.” In the 2018 IBC, the title of this section was changed to “Door hardware release of electrically locked egress doors” in an attempt to further clarify where the section applies.

There’s nothing wrong with specifying the additional release methods for a door with a mag-lock released by door-mounted hardware, but the fire alarm release and auxiliary push button are not currently required by code for that application.

– Lori

One point that I failed to make is that while we hate mag locks, some of us used to hate vertical rod exit devices even more. (This was before the VD99 cable devices). University students are hard enough on doors without the rods to bend and they always seem to need adjustment (even the concealed ones). Our predecessors used a pair of doors with no mullion and mag locks to avoid the vertical rod devices. This made for two of everything. On the rare chance that a switch failed closed, the other door of the pair would still open both doors. Everything was in series and any failure opened both doors. Our past people have only rarely planned a mag lock for a single door, and we have replaced almost all of those. All of our new installations are some type of electrical latch retraction or electrified trim. Mag locks are a last resort and we only have one pair that is less than 10 years old. It is a delayed egress system into a swimming pool area that is closed at times but still an emergency exit path. We have removed more that two dozen mag locks in the last 5 years.

I’d love to hear about your experience with the concealed vertical cable devices. Maybe a guest blog post? 😀

– Lori

In the case where there are all glass doors which are required to be secured; I’ve looked into a few types of panic handles, which are compatible with full glass doors, that allow you to utilize electric strikes at the top of the door frame (as opposed to a maglock).

I’ve only been able to find two products which currently can achieve this:

– PRL Glass Systems has a panic handle (PL-100a) which works with electric strikes in the top of the door frame.

– CRL Laurence also has a similar panic handle available.

(here is a press release talking about the operation of the handle & strikes: http://www.crlaurence.com/adv/Press_Releases/releases/electric_strike_keeper.html)

Would these be an acceptable alternate to maglocks for all glass doors?

Are there any concerns you can see with using this style of hardware?

Hi Dave –

I have used that type of panic hardware before and I can’t think of any concerns when using the style that latches into the head. The one that latches into the floor conflicts with the requirement for a flush, smooth surface 10 inches up the push-side face of manual doors.

– Lori