The increase in fire door assembly inspections – particularly in health care facilities – is resulting in LOTS of questions about fire door assemblies. The most FAQ in the last few weeks has been…

When a fire door has more clearance than what is allowed by NFPA 80, can a door sweep and/or gasketing be added to solve the problem?

Excessive clearance is one of the most common problems found with existing fire door assemblies. NFPA 80 – Standard for Fire Doors and Other Opening Protectives limits perimeter and meeting stile clearance to a maximum of 1/8 inch for wood doors and 1/8 inch +/- 1/16 inch for steel doors, when measured on the pull-side face of the door (see below for a change related to 20-minute doors*). For most fire doors, clearance at the bottom of the door is limited to 3/4 inch.

There are many types of gasketing, thresholds, door bottoms, and sweeps that are listed for use on a fire door. However, almost all of these products are designed and tested for use on doors which have clearances within the acceptable limits shown in NFPA 80. Installing this gasketing on a non-compliant fire door assembly will not bring the opening back into compliance.

Crown Fire Door Products invited me to attend a test at UL a few years ago, and I wrote about it for Doors & Hardware magazine. Click on the photo of Uriah Noble installing Crown’s door extender to read the article. Photos courtesy of Leslie Miller, Fire Protection Publications

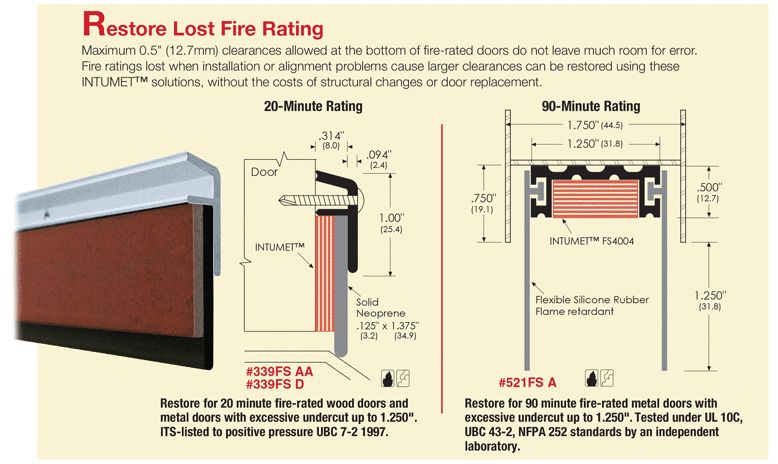

Several products have been introduced in the last few years that are tested and listed for use on fire doors with clearance that exceeds what is allowed by NFPA 80. When using these products, it’s very important to consider the limitations of the product – for example, the maximum clearance that the product has been tested to accommodate, the door/frame material, and the rating.

The 2016 edition of NFPA 80 has been updated to include references to this type of product, allowing their use for doors with clearance in excess of what is allowed by the standard when the products are installed in accordance with their listings. Prior to the 2016 edition, NFPA 80 does not mention any methods of resolving oversized-clearance problems, but the standard does address alternative methods and equivalency, which would allow AHJ approval of listed products even if they are not specifically addressed in NFPA 80.

One thing to keep in mind, which is mentioned in the 2016 edition of NFPA 80 and in the NFPA 80 Handbook, is projection of the latchbolt. If the clearance is too large, latchbolts at the bottom of the door or on the latch edge may not engage the strike securely enough. To determine the minimum engagement, refer to the manufacturer’s listings – according to the NFPA Handbook, most latches are required to engage the strike by 11/16 inch. If gasketing and/or door bottoms are added to an existing door, the assembly must be tested to ensure that the door will still close and latch properly. Shimming the hinges with steel shims may help to decrease the latch-side clearance.

Listed below are the products that I have seen, that can be used when fire doors have excess clearance. If you know of other products, please leave them in the reply box and I will add them.

- Zero International – sweeps and door bottoms

- National Guard Products – perimeter seals and door bottoms, steel stop extender

- Crown Fire Door Products – door stops and door extensions

- Markar Products – edge guards and continuous hinges with edge guards

* The 2016 and 2019 editions of NFPA 80 also allow the extra tolerance of +/- 1/16 inch for high-pressure decorative laminate (HPDL)-faced doors, flush wood doors, and stile and rail wood doors installed in hollow metal frames – when the assembly is rated for 20 minutes. Assemblies of these types that are rated for more than 20 minutes are limited to 1/8-inch clearance between the door and frame, and at the meeting stiles of pairs. Doors constructed of other materials (not including hollow metal doors) are limited to 1/8-inch clearance unless permitted by the door, frame, and latching hardware listings.

You need to login or register to bookmark/favorite this content.

Thank you for the info

Lori,

Would you please send 50 of the laminated cards to me?

Don Hicks

Overhead Door Company Of Atlanta

221 Armour Drive NE

Atlanta GA 30324

Great information, thank you. What is this NFPA handbook, and where can I get a copy? Is it distributed by the NFPA, or an outside source? My concern is the 11/16″ engagement. I’ve researched this everywhere and have yet to find a code that lists how far a latch needs to engage, or penetrate. I’ve seen “minimum throw”, but never engagement. Any help you can offer would be much appreciated. Thanks again.

Hi Robby –

NFPA has handbooks for several of their codes and standards. The NFPA 80-2016 Handbook is available here: http://catalog.nfpa.org/NFPA-80-Standard-for-Fire-Doors-and-Other-Opening-Protectives-P1204.aspx?icid=D729, and there are several editions of the NFPA 101 Handbook here: http://catalog.nfpa.org/NFPA-101-C3317.aspx.

– Lori

Hi Lori

I would like to further explore Mr. Castro’s inquiry as you didn’t specifically address the 11/16″ flush bolt/ strike engagement. Years ago, while attending DHI’s FDAI (600) course, the text book stated that the flushbolt should engage the floor strike one half inch (minimum). At the time, we could not find anywhere in the listings or manufacture’s instructions, stating this required adjustment. I even asked Mr. Pardo. He said that the half-inch engagement is based on a mathematical formula where the margin between the bottom of the door (flush bolt head) and top of floor strike is 1/4″. This is based on 3/4″ flush bolt throw. [After factoring a 1/8″ margin between the meeting stiles.]

We have (again) looked at the UL listings, as well as manufacturer’s installation instructions for several well respected brands, including Ives and DCI. To date, we have not found any dimensions for either projection or strike engagement listed.

Can you direct us further or provide clarification? Thank you.

I have looked for this too, and have not found where it states the specific amount of engagement required. Hopefully someone else will know where to find it.

– Lori

Hi Lori,

The handbook commentary was revised in 2016 from 1/2 in. to 11/16 in.

below is the 2016 handbook commentary.

6.3.1.7.1 *

Clearances dimensions between doors and frames and meeting stiles of paired doors shall be measured on the pull side of the assemblies.

There are potentially grave consequences when the clearances around the perimeter of a fire door exceed the tolerances allowed in NFPA 80. For example, the majority of latching hardware items are required to engage their respective strikes by 11/16 in. (12.7 mm). Consequently, most latching hardware items are designed with latch bolts that project 5/8 in. to 3/4 in. (15.8 mm to 19 mm). On hollow metal doors, the clearance between the vertical edges of the door and frame (and meeting stiles of pairs of doors) is 1/8 in., plus or minus 11/16 in. (3.18 mm, plus or minus 1.59 mm), allowing the maximum clearance to be 3/16 in. (4.76 mm).

When the clearance between the door and frame exceeds 3/16 in. (4.76 mm), it reduces the latch bolt engagement dimension. In a fire, hollow metal doors will deflect, warp, and twist as the temperature of the fire intensifies, but through it all the latch bolts need to remain positively latched in their strikes and hold the doors in the closed position. If the clearances are too great, it is very likely that the latching hardware will fail during a fire and the doors will open, allowing the spread of smoke, gases, and flames.

Significant changes were made to 6.3.1.7 in the 2016 edition. For many years, NFPA 80’s clearance dimensions between door frames and doors remained static. They covered steel doors (i.e., hollow metal doors) and wood doors, irrespective of the door frame material or construction.

It’s important to know that NFPA 80’s clearance dimension requirements for wood doors are based on the clearance dimensions allowed in the fire door test standards (e.g., NFPA 252, UL 10B, and UL 10C). Each of the fire door test standards allows a maximum of 1/8 in. (3.18 mm) clearance dimension between the door frames and doors and meeting stiles of paired doors (no over-tolerances are permitted), regardless of the door frame or door construction. Clearance dimensions for wood doors have remained unchanged for nearly 50 years.

NFPA 80’s clearance dimension requirements for hollow metal doors vary from the fire door test standards by allowing an additional 1/16 in. (1.59 mm) over-tolerance and requiring a minimum clearance of 1/16 in. (1.59 mm); no minimum clearance dimension is required by the fire door test standards. These variances have been part of NFPA 80 since the 1990 edition.

Since the introduction of periodic inspection and testing of fire door assemblies in the 2007 edition, excessive clearance dimensions on existing doors has been one of the most frequently cited deficiencies, especially for wood fire doors. Accordingly, the technical committee pursued research that might provide technical justification for changing NFPA 80’s clearance dimensions for wood doors. To date, no substantive research has been completed that would provide the technical committee with the technical justification needed to support any changes.

Absent the needed justification, the technical committee expanded 6.3.1.7 to address all of the door frame and door construction and materials used on the door assemblies covered in Chapter 6.

Paragraph 6.3.1.7.2 retains the clearance dimensions for hollow metal (i.e., steel) doors; no changes were made to these requirements. These doors can be rated up to 3 hours.

Paragraph 6.3.1.7.3 allows an additional over-tolerance of 1/16 in. (1.59 mm) for flush wood doors, stile and rail wood doors, and HPDL-faced doors, provided these doors are 1/3-hour (20 minute) rated and installed in hollow metal door frames. The technical committee determined that allowing the additional over-tolerance dimension for these particular fire door assemblies would not adversely affect their performance. It should be noted that when these ⅓-hour rated doors are installed in door frames of other materials, the additional over-tolerance dimension is not allowed; this is not clearly stated in NFPA 80, however.

Paragraph 6.3.1.7.4 retains the 1/8 in. (3.18 mm) maximum clearance for flush wood doors, stile and rail wood doors, and HPDL-faced doors that are rated for more than 1/3-hour, regardless of the door frame construction or material.

Paragraph 6.3.1.7.5 limits the clearance dimension on doors that are constructed of other materials (e.g., aluminum and FRP) to a maximum of 1/8 in. (3.18 mm), unless otherwise permitted by the respective manufacturer’s published listings. This provision might also lead to testing other types of door construction with clearance dimensions greater than 1/8 in. (3.18 mm).

New guidance regarding the expanded provisions of 6.3.1.7 appears in Annex A (see A.6.3.1.7, A.6.3.1.7.2, A.6.3.1.7.4, and A.6.3.1.7.5).