The US Access Board has added a guide to their website, which explains the ADA standards in detail. So far, only Chapters 1-3 have been posted, and most of the door-related information is in Chapter 4, but there is a lot of good information relative to the basic ADA requirements. There are also animations on the site which illustrate wheelchair maneuvering, accessible toilet rooms, maneuvering at doors, and accessible bathing facilities. There are a few things to note with regard to what has been posted on the site so far, particularly regarding Chapter 3. The “Common Questions” section includes these 2 questions and answers:

Must operable parts be usable with a closed fist?

Closed-fist operation is a good performance test but is not required by the standards. Many types of operable parts, such as pull handles, satisfy the requirements even though they may not be operable with a closed fist.

Are turn-key locks prohibited by the standards?

Key locks or key cards are not prohibited by the standards which apply only to the fixed portions of operable parts. Similarly, items dispensed by ATMs and fare machines, such as receipts, cash, fare cards, and vending machine products are not covered by the standards.

These answers are the same as the answers I’ve been giving when these questions were asked, but it always helps to have the US Access Board put it in writing. There isn’t currently a required projection for door pulls, or code language that requires a specific amount of clearance behind the pull to accommodate a closed fist (here’s where I wrote about door pulls). In the absence of prescriptive code language, some have applied the clearance dimension for handrails (1 1/2 inches) to door pulls. There’s nothing wrong with that, but it’s not mandatory to have 1 1/2 inches of clearance behind a door pull unless it is a local code requirement. I have been told by several accessibility experts that there should be enough clearance for a flat hand to slide through, but again, there is no code requirement stating that.

Keys are a tough topic to address, because the accessibility standards mandate operable hardware which does not require tight grasping, tight pinching, or twisting of the wrist to operate. Keys obviously require tight grasping, tight pinching, and twisting of the wrist, so why are keys acceptable and knobs are not? As the Access Board’s response states, the standards only apply to fixed portions of the operable parts (they are using “fixed” to mean permanent, not stationary), and keys are not a permanent part of the lock. A modification may be required – for example, a proximity reader – if a person is unable to operate a keyed lock, but the standard does not prohibit keyed locks in general.

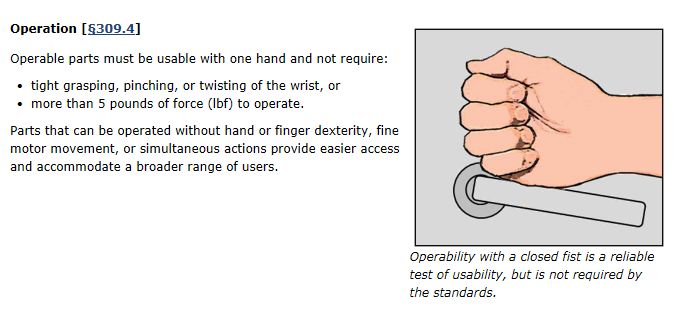

Another interesting item included in the guide is this section on Operation (309.4):

My column in the May issue of Doors & Hardware is about the change to the 2010 ADA which requires hardware to be operable with 5 pounds of force. I was originally told by the Access Board that they recognized there was a conflict between the opening force section (which says the 5-pound opening force does not apply to the force required to release the latch), and the operation section (which says operable parts must not require more than 5 pounds of force to operate). The person I spoke to from the Access Board back in 2012 said she would recommend removal of the 5-pound requirement for hardware. However, the guide reinforces the 5-pound requirement by using an illustration of door hardware with the explanation of this section. If the requirement was going to be removed, the introduction of this guide would have been a good time to make that clear.

Check out the US Access Board Guide to the 2010 ADA Standards by clicking here. I’ll let you know when the guide to Chapter 4 becomes available.

Meanwhile, let me know if you are running into enforcement of the 5-pound force requirement, or have decided to specify/supply products which operate with a maximum of 5 pounds of force to avoid future ADA issues.

You need to login or register to bookmark/favorite this content.

This new ADA update is excellent! Thank you for keeping us up to date with the latest info.

The guide clarifies the questions we have discussed before regarding keys and ADA compliance.

So here’s the question that remains for me when considering the Schlage ND53 or Best 93k-AB function that we have currently specified:

The push and turn button would obviously qualify as a “fixed portion” of the operable part of the lock. This would seem to make this particular function non-compliant. Except when one considers the following:

1 – This function still allows the “locking” operation to be engaged by pushing the P&T button.

2 – This function still allows the “unlocking” operation to function by operating the inside lever.

3 – The only operable part that is not easy to operate is the “turning” operation which only functions to keep the outside lever locked. I would contend that the operable part that allows “keeping” the outer lever locked is NOT hindering the primary ACCESS or even the secondary operations of the lever lock.

Conclusion: The PRIMARY “operable” functions provided by this and most cylindrical lever locks are ADA compliant because the ACCESS OPERATIONS really only include:

1 – Unlatching the door for egress.

2 – Unlatching the unlocked door for entering.

Even the SECONDARY “operable” functions are ADA compliant because they only include:

1 – Locking the door.

2 – Unlocking the door.

Am I missing something?

I’d be interested to know if others disagree with this line of reasoning.

Hi David –

I agree with all of your points, but I have still had AHJs reject the turn-button. I think it does meet the intent of the standard for all of the reasons you stated, but I think there will always be a bit of a grey area.

– Lori

Just today I explained to a school Main tenancy director the difficulty of attaining this goal and convinced him to use ADA operator. In this case a Record 8100.

My name is Ken Stephens with a company called Dustco Building Specialties in Denver, CO. We furnish and install trash chutes that require various ADA and NFPA Fire code compliance. The email chain below is the result of trying to understand the ADA side of the hardware for the trash chutes. The stance from Wilkinson High Rise (the manufacturer of the trash chutes) has been that their lever handles are ADA compliant. The President of Wilkinson just forwarded me an article from a blog that I believe you created from April of 2014 that addresses this issue. Has there been a change to his code requirement as it seems the blog is an informationl site used to state opinion and status of the ADA code rather that a usable reference to substantiate the lever handles compliance. If I am wrong on this please let me know. I am relatively new to this and want to make sure my interpretation is correct.

I understand that per ANSI 117.1, this does not address the “Pull Force” of the doors and perhaps that is a completely separate issue. I am just trying to correctly educate myself on the hardware portion of the ADA code and start there.

I am hoping you are still out there and will share with me your knowledge on the subject.

Thank you and have a great day!

Hi Ken – I’m still out here! 🙂

The information written by me on my site is not an official interpretation of the codes and standards, but the ADA guide referenced in the post where you left your comment is put out by the US Access Board. There is guidance there that is not included in the ADA standard so it could be disputed, but it is used by AHJs to interpret the requirements.

Let me know if you have specific questions, but here are a few things about hardware:

– Operable hardware must be operated with no tight grasping, tight pinching, or twisting of the wrist, and with no key, tool, special knowledge or effort.

– Doors in a means of egress must unlatch with one operation.

– Hardware must be mounted between 34 inches and 48 inches AFF.

– The ADA requires hardware to be operated with a maximum of 5 pounds of force. A117.1 does not include this requirement.

I have more information on all of these requirements. Let me know what questions you have.

– Lori

Hi Lori,

You mentioned “no keyed” access to meet ADA hardware requirement…?

We are using ADA compliant handsets for an office bldg. Our client wants each to be keyed (push button lock/release on inside). Is this going to be a problem??

Thanks,

Susan

Hi Susan –

A key requires tight grasping, pinching, and twisting, so it may be difficult for people with certain types of disabilities to use keys. However, the accessibility standards don’t regulate keys because they are not attached to the door. Locks with a key cylinder on the outside and a push button (not a turn button) on the inside would meet the accessibility requirements, but if there is someone who uses the door regularly and can not operate the lock using the key, the facility may need to make accommodations for that person.

– Lori

Thanks Lori. We really appreciate it. One last question. Do you know of an ADA compliant source for a flush (recessed) pull for a sliding door? We have 3 offices with sliding, surface mounted doors. There’s no need for a lock. I know they have to be “C” or “U” shaped but can’t seem to find any other specs…other than no tight grasping, pinching, etc. The only manufacturer I’ve seen that says their pull is ADA approved is Trimco.

Hi Susan –

I don’t know of a recessed pull that would be ADA compliant, but that doesn’t mean that there isn’t one. The standards are not specific about pulls, although the ADA guide says that there should be 1 1/2 inches of clearance behind the pull so that’s something you can look for. The hardware has to be exposed and usable from both sides when the door is fully open, so the old fully-recessed pulls are no longer allowed.

– Lori