Panic hardware, also known as an exit device (or fire exit hardware when used on fire doors), is designed to provide fast and easy egress to allow building occupants to exit safely in an emergency. Code publications define panic hardware as, “a door-latching assembly incorporating a device that releases the latch upon the application of a force in the direction of egress travel.” Panic hardware may also be used because of durability or ease of use, even when it is not required by code.

Code Requirements

The Life Safety Code (NFPA 101) and the International Building Code (IBC) both include requirements pertaining to panic hardware. Local codes may be different, so be aware of any special requirements for your jurisdiction. The IBC and NFPA requirements vary depending on which publication and edition are being enforced:

- IBC 2006, 2009, 2012 – Each door in a means of egress equipped with latches or locks serving:

- Assembly or Educational Occupancies with an occupant load of 50 people or more.

- High Hazard occupancies (any occupant load).

- IBC 2003 – Each door in a means of egress equipped with latches or locks serving:

- Assembly or Educational Occupancies with an occupant load of 100 people or more.

- High Hazard (H-1, H-2, H-3, or H-5) Occupancies (any occupant load).

- NFPA 101 – Required means of egress doors equipped with latches or locks serving:

- Assembly, Educational, or Day Care Occupancies with an occupant load of 100 people or more.

- High hazard contents areas with an occupant load in excess of 5.

The National Electric Code (NFPA 70) contains requirements for panic hardware on doors serving rooms housing electrical equipment of more than 600 volts or more than 1200 amps (800 amps per the 2014 edition), when the door is within 25 feet of the required working space. The IBC also requires panic hardware on some electrical rooms. (Here’s more information about the NEC requirements.)

The AHJ may request panic hardware in other instances if he or she believes that panic hardware is required for life safety. If a door is not equipped with a latch or lock (push/pull application), the door is not required to have panic hardware. Keep in mind that when an application requires panic hardware, all of the doors in the means of egress from that room or area will typically require panic hardware, including the exit access, the exit, and the exit discharge. The exception to this rule is the code requirement for panic hardware on electrical rooms, which includes only the doors within 25 feet of the required working space.

Other Code Considerations

- Where panic hardware is required, the actuating portion of the device (touchpad or crossbar) must be at least half the width of the door leaf.

- Current codes require panic hardware to be mounted between 34 inches and 48 inches above the floor. Existing panic hardware may have been installed in accordance with previous code requirements.

- A force of 15 pounds applied to the touch-pad or cross-bar must release the latch. Some codes have recently been modified to require door hardware to operate with 5 pounds of force, which has created a conflict between the code requirements.

- No additional locking device (deadlock, chain, padlock & hasp, etc.) may be installed on a door required to have a panic device, and panic hardware may not be equipped with any device that prevents the release of the latch when the touch-pad or cross-bar is pressed. The exception to this is a delayed egress device.

- When panic hardware is used on fire doors, it must be fire exit hardware and the door must be equipped with a label stating “Fire Door to be Equipped with Fire Exit Hardware.” Fire exit hardware is labeled for panic and fire, and is not equipped with a mechanical “dogging” mechanism. An electric latch retraction device may be used to provide dogging for fire exit hardware, as long as the latch projects automatically upon actuation of the smoke detection system.

- If panic hardware is used on balanced doors (doors where the pivot point is located several inches in from the hinge edge of the door) a pushpad/touchpad device must be used and the actuating portion of the device must not extend more than half the width of the door. Crossbar style devices may not be used on balanced doors. The reason for this is that if the actuating portion extended all the way over to the hinge edge of the door, a building occupant could push on the wrong end of the panic device and the door would not open.

- In some jurisdictions, doors and hardware must meet testing requirements for hurricane and tornado protection. Consult the applicable codes and manufacturers’ certifications for compliance information.

Selection Criteria

Style: There are three basic types of panic hardware, dependent on aesthetic requirements, door design, and sometimes other factors.

- The touchpad style is the most common style used for modern buildings, and allows flexibility when electrified options are required – electrified lever trim, electric latch retraction, or delayed egress.

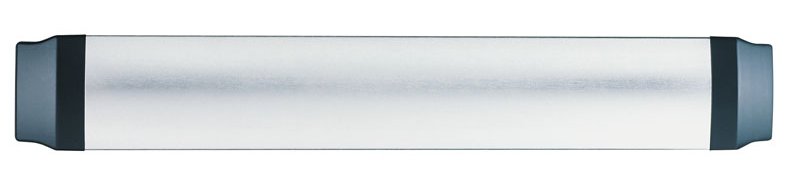

- The crossbar style is often used when aesthetics dictate a minimal silhouette for glass doors, or a vintage look, but the electrified options are sometimes limited because of the lack of space in the device to house electronic components. The width of a door’s vertical stiles must be considered when specifying or supplying touchpad or crossbar style panic hardware.

- Recessed panic hardware reduces the projection of the hardware from the face of the door, but requires a cut-out in the door and may limit the door material to hollow metal.

Type: Various types of panic hardware are available, based on whether it is used on a single or pair of doors, and functional requirements:

- Rim – A rim panic device is surface-mounted on the door, with the latch projecting from the panic device rather than the door edge. This is the simplest configuration of panic hardware, and the easiest to maintain. Rim panics can be used on single doors, or on pairs of doors in conjunction with a removable mullion. The rim x rim x removable mullion is a very secure application for pairs of doors, because the alignment of the doors is less critical than vertical rod devices. A key-removable mullion makes the mullion easy for authorized users to remove.

- Mortise – A mortise panic device has a mortise lock body which is installed in the door, with the panic hardware mounted on the door face but controlling the mortise lock. Mortise panics are less commonly used than rim panics, likely because of the more complex door preparation and product design. For fire rated pairs with a 3-hour label, mortise fire exit hardware is sometimes used in conjunction with vertical rod fire exit hardware on the other leaf, but some manufacturers have successfully tested their products for 3 hours with vertical rod fire exit hardware on both leaves.

- Vertical Rod / Cable – These would typically be used for pairs of doors, and the rods and latches may be surface-mounted on the face of the door, or concealed inside of the door. For concealed applications, there is also a device available which incorporates cables instead of rods, for easier installation and maintenance. Vertical rod fire exit hardware is sometimes installed “less bottom rod” (LBR), which allows floor strikes to be omitted along with the bottom rods and latches. An auxiliary pin is typically required to ensure alignment during a fire.

- Multi-Point – A multi-point device combines vertical rods and a rim device, for 3-point latching. These may be used for security purposes, or to meet windstorm requirements.

Other Options

Trims and Controls – The outside trim or control is used to retract the panic hardware latch(es) from the exterior. The exit-only function has no exterior trim. Nightlatch function is typically used where panic hardware is “dogged” to unlock the door, and may have a cylinder only, a cylinder and a pull handle, or a cylinder with a fixed lever handle. In some cases, a thumbpiece may be used in addition to the cylinder, to provide additional leverage to retract the latches. Lever trim is available in passage, storeroom, or classroom functions, as well as electrified functions. Knobs and thumbpiece trims are also available, although they are less commonly used because of current accessibility requirements.

Finishes – Panic hardware is available in a variety of finishes, including architectural plated finishes, stainless steel (when the base material is stainless steel), and powder coat finishes – both standard and custom colors.

Dogging – The act of dogging a panic device holds the latch(es) retracted to allow the door to operate as a push-pull function. This saves wear and tear on the hardware, and makes it easier for building occupants to use. Dogging may be done via hex-key or key cylinder, and must be specified with the preferred option. The mechanical dogging function is not available for fire doors because the doors must have an active latch bolt for positive latching, but electric latch retraction may be used to provide the same function.

Electrified Functions – Panic hardware can be supplied with electric latch retraction, electrified lever trim, delayed egress, alarms, switches, or other electrified options to meet the access control and monitoring needs of the facility.

Conclusion

For questions about panic hardware options, assistance with special applications, or a complete specification, Ingersoll Rand Security Technologies has more than 100 specification writers and architectural consultants available to help. We are also an AIA/CES approved provider, and conduct a wide range of courses offering AIA continuing education units. For help with code-compliance and product application, explore idighardware.com, where you can ask a specific question using the Help button.

Click here to download a PDF version of this article. Please pass it on if you know someone who can use it.

You need to login or register to bookmark/favorite this content.

Lori,

Thank you for this great article! As a young architect, it took me several projects/ years to become familiar with all these basics. This will be a useful reference both internally and with clients. With the basics covered, we can make better use of time spent with consultants like yourself!

Thanks Karl! I appreciate the feedback!

Karl,

Take it from a Old Architect. Always dig deeper into the code. Many times there are exceptions, and you owe it to your clients to give them all the options.

I’m glad your following Lori’s blog. It’s a wealth of information and an occasional good laugh.

Jeff

Dear Lori, thank you for the useful “basic”.

Could you please provide images of the types? I am not sure of the difference between “vertical rod” and “multi-point” – on google they appear to be the same thing… Thank you 🙂

There are exceptions to the panic hardware requirement under the the IBC. This is a little misleading because it seems to indicate that panic hardware is required for “A” occupancies of 50 or more and that is not case with exception 1008.1.8.3 item 2. True?

You’re right – there is an exception, although it’s quite limited and I don’t often see it used. I meant to add a note, and I will edit the post. Thanks!

Lori,

I have opened a can of worms…

The discussion involves an existing door with a Rim type exit device installed. The door width is 40″ (odd but true).

The discussion involves the wording of the OBC and I believe the IBC is similar. The “actuating portion” of the releasing device shall extend at least one-half od the door leaf width.

I agree with your note in your article; actuating portion must be at least half the width of teh door leaf.

The discussion is that the existing exit device “actuating portion” extends past the middle of the door as it is installed.

Any guidance here?

Thanks!

Don

Hi Don –

You are the second person to ask me about that in the last year. If I’m understanding you correctly, your question is whether the touchpad would need to be at least 20″ wide for a 40″ door, or whether it just needs to extend past the 20″ midpoint of the door. In the latter case, a device with an 18″ touchpad would work because it would typically start a few inches in from the edge and extend past 20″. BUT…in my opinion that is not the intent of the codes. The IBC says, “The actuating portion of the releasing device shall extend at least one-half of the door leaf width.” NFPA 101 says, “It shall consist of a cross bar or a push pad, the actuating portion of which extends across not less than one-half of the width of the door leaf.” I guess the language could be interpreted either way, but there’s a graphic in the IBC Commentary that helps to illustrate the intent: http://idighardware.com/wp-content/uploads/2011/05/Panic-Hardware-Actuator1.jpg.

An AHJ may interpret it differently, or may allow the 18″ touchpad on a 40″ door even though it’s not quite long enough, but from my research the last time someone asked, that is not the intent of the requirement.

– Lori

Thanks! I feel that I was taught well and agree!

Lori,

I work in the curtainwall industry and am woefully ignorant on the field of door hardware.Ive been eager to learn it but most employers are reluctant to pay a man while training him.Please give me some advice as to when and where I can get formal training on this subject.I am in Cleveland Ohio.

thank you for your attention,

Peter

Hi Peter –

The Door & Hardware Institute offers a lot of courses that might help you (dhi.org). I can help with code-related training…there’s a link on this page to join the notification list for the next online course: http://idighardware.com/decoded-course/.

– Lori

Hi Lori,

In terms of Fire exit vertical rods, is there any sort of advantage or advice based on codes requirement to select surface mounted fire exit vertical rods over concealed types?

Will highly appreciate if you could advice.

Thanks and regards.

Sajjath

Hi Sajjath –

For manual doors, the surface-mounted vertical rod conflicts with the requirement for a 10-inch smooth surface at the bottom of the door on the push side. You can use surface vertical rods “less bottom rod,” but if you want 2-point latching you would have to use concealed vertical rod or concealed vertical cable devices.

– Lori

Thanks Lori, That makes sense to me. Still, How does the door prep for the CVR/CVC impact on the fire rating of the door where as we need not to do any prep for the Surface mounted types?

Also when it comes to the health care sector should we worry about bacterial issues inside the door prep of CCR?

Thanks again.

Sajjath

Hi Sajjath –

As long as the prep for the CVR is done at the factory / in the shop (not in the field), there is no problem. I have not heard of any bacterial issues, so I’m not sure about that.

– Lori

That is really cool how a crossbar style for panic hardware gives a more vintage look on the door. That would be something that I would get for a door for an emergency exit or a backdoor or something. They seem like they would be good for those uses when it comes to panic hardware.