Thanks for your patience, everyone. My week “off” was followed by our Thanksgiving holiday, so I haven’t posted as much lately. But I’m back, and I saw lots of doors while I was away.

A question was sent to me recently by Dr. Nabil Hanna of Merryland International in Egypt. I ran out of ideas to help with his situation so I thought I’d see what you all could come up with. I have had many cases in the past where an architect wanted to do something that seemed impossible or at least implausible, and I have sometimes seen AHJs allow applications that might not have been addressed by the code, but met the intent and were acceptable to them. For fire doors, there’s a section in NFPA 80 that addresses the use of new products that meet the intent of the standard:

NFPA 80-2007, 1.4 Equivalency.

1.4.1* This standard shall not prohibit the development of new, modified, or improved devices that meet the intent of these requirements.

1.4.2 It shall be the responsibility of the manufacturer to furnish the information necessary to update the requirements pertaining to such new and improved devices.

1.4.3 For devices not described in this standard, theAHJ shall request descriptive information from manufacturers that is provided by a testing laboratory concerning acceptable methods for satisfactory field installation based on fire tests and engineering studies for operation and maintenance considerations, where applicable.

From Annex A:

A.1.4.1 The development of fire doors and related devices is a continuous process; therefore, this standard is not always current. This standard is intended to be current only at the date of publication.

The doors are supposed to be 90-minute rated. The facility needs a 12′ wide opening to move equipment through approximately once per day. It is also a required means of egress, and the width of egress doors is limited to 48″ wide per leaf. The doors are 9′-6″ high, hollow metal. Some are double-egress and some are standard pairs.

One idea that was suggested was to have a center pair hinged to doors that are fixed in place with constant-latching flush bolts until the 12′ width was needed. There are obvious issues with this – I’m sure the application hasn’t been tested, there’s no stop at the hinge edge to help prevent smoke infiltration, and then there’s the question of how to make the center pair automatic-closing.

So, what would you suggest to the architect to allow for a 12′ clear width on occasion, meet the egress requirements the rest of the time, and meet the intent of NFPA 80 as much as possible? I’m all ears.

You need to login or register to bookmark/favorite this content.

Lori, maybe I am missing part of the issue, but my suggestion would be an overhead coiling fire door with a hinged egress door built into it. They could keep the coiling door open at all times – just have it connected to the fire alarm. The egress door is only used in case of fire when the coiling door would be closed. This link shows an example: http://www.mckeondoor.com/new-product/Fire%20and%20Smoke%20Rated%20Doors%20with%20Egress/Vertical%20Coiling

Just shooting from the hip here…Would pockets be allowed on the perimeter to slide the last 2′ into the wall (could depend on packet and wall construction for fire rating)? This would also require full length welded hinge guards w/ smoke seal to seal the openings instead of a stop. Then for automatic closing… a detachable closer arm with top of jamb mount.

How about removeable HM mullions with a fixed panel between them.

Mount the doors to far outsides of the 12′ opening and mount the mullions with panel in center. Since this would be construction fire rating only, you could use either rim devices or mortise devices on the doors to latch into the mullions.

For ease of removing the middle section, install cylinder keyed threshold & header bolts with extention rods, so you have one keyed cylinder per mullion. And while we are inventing stuff, flip down wheels will assist is rolling the middle panel section out of the way.

On the double egress pairs, change to RH/LHR swing doors from an equal rabbet profile & mullions.

You will have to re-think the standard removeable HM mullion base anchors so that there is not a hinderance to moving the equipment through. That is why I was suggesting the threshold bolts installed into the mullions.

Have you considered vertical acting/coiling fire doors with pass doors, such as McKeon’s Safescape® T2000 Series Fire Door Systems?

I would go for a variance for 6′ plus wide doors first, wide enough to attain the 12′ clear requirement.

Won dor.

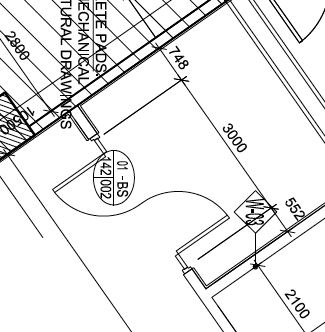

Agree with accordion door IF you can fit the pocket construction into the corridor and still leave 12′. Can’t tell the dimensions of the ‘short walls’ from the drawing. Won’s new cross corridor door (coming out in Jan) will not need a leading edge pocket now, and the main pocket size has been reduced quite a bit. Tell them to call me, we are a Won factory trained and certified dealer. I believe the only non-factory dealer.

Zeke may need two doors if they each have to swing in direction of travel both ways

http://www.cleansealdoors.com/products/265___ssfp_door_page.php

@ same-direction swing, how about unequal leafs? Egress leaf would be 4′ wide, and then have a specially-constructed 8′ wide inactive leaf (definitely on pivots…). Presumption is that the 4′ wide leaf would suffice for exit width. Mag h.o. needed here?

@ dbl-egress: trickier, but again how about unequal leafs? We’d have to treat the inactive leaf in both swing types as a utility door with sufficiently sized bolts (don’t know if manual flushbolts would suffice).

Krieger Specialty Products out here on the left coast, or Overly out your way, can likely build that 8-0 x 9-6 leaf with a provisional label.

Please keep us posted with how you finally resolve this one — thanks for putting it out there. Hope Thanksgiving was wonderful for you & your family.

we came up with a panel solution that has worked previously: A university needed to get equipment through, but not all the time. We designed a standard HMF with an extra 36″ in the middle, and built a 36″ hollow metal panel. We put ASA strikes into each side, and used a piece of angle iron welded to the top (with an 1/8″ gap to allow the door to slide in). It worked by having two technicians (these were steel stiffened doors) lift the panel into place, where it was captured by the angle. We then screwed another piece of angle near the bottom of the door, drilled and tapped for three 3/8″ bolts. We had a threshold in our application, but just as easily could have used a small strike screwed into the floor to hold the bolts. Then, you simply turn the bolts in or out to level and square the door, and presto, you’ve got latching, fire rated opening, while still being able to move large equipment through. Our opening was 9′ wide by 9’6″ high. We did this a few times very successfully.

Contact Rixson Engineering to engineer a set of pivots to handle the weight and frequency of a 6′ x 9’6″ assembly. A 2′ panel could be used with the engineered pivot set attached to the frame. Extra heavy duty UL labeled surface bolts top and bottom could be used to set the 2′ panel in place; half mortise cont. hinges could support the 48″ door attached to the panel. The 48″ doors will need to be held open and conected to the FA system as this application will not be durable.

Any functional door in this opening will not be a tested unit, and thus will be subject to AHJ’s approval.

The unit proposed by you is functional but with the following add ons :

A. Hinged door to have 4nos 6″ x 4.5″ hinges as it has to carry weight of inactive leaf of the center pair door

B. A castor wheel at the leading edge of hinged door to prevent the sag

C. Spring hinges on inactive leaf of center pair door

D. Flat plate astragal fixed on leading edge of hinged door.

Active leaf of center pair door can have butt hinges to suit and a regular door closer.

Hi Lori

I like the original idea of hinge the active egress doors off of the fixed laefs.

Givin that there probably is not a fire reated assembly that exists for this situation the best we can do is use fire rated products and get as close to code as possible.

So here is my idea: The fixed (outside)leafs would be mounted on continuous swing clear hinges with self lacthing flush bolts on the leading edge. The active leaf would be mounted to the fixed leaf with a full surface continuous hinge with vertical rod exit devices for latching (possibly LBR x Fire Pin). I would control all 4 of the doors with a concealled door closer (jamb to door mount similar to Samual Heath Perko Power) Gasketing could be placed in between the fixed and active leafs for smoke control as well as at the perimeter and a non-overlapping astragal at the meeting edge of the active doors. Lastly, magnetic hold opens would be used to hold the doors open during the equipment moving operation and would insure that the doors would close upon alarm signal if they were left open. Of course all of the hardware would have to be confirmed to meet the weight and rating requirements.

To all

Thanks for sharing with your thoughts regarding these unusual openings.

Here are my comments:

1. Using overhead coiling is not accepted as there is no enough room over the top of the doors.

2. Pocket will not work.

3. Mullions also will not working as for the de-assembly of the mullion and the panels is not accepted by the client or the operator.

4. Using of overhead closer will not work as you have to de-assemble the closer arm .

5. Using side jamb Power Matic Perko closer is a good solution , but these closers were tested only for 45 min steel doors or 60 min wood doors but not 90 min.

6. Our decision is to use the original proposal (spring hinges on rebate doors to have a stop) and as Lori mentioned that we can be covered by the NFPA80 Paragraph 1.4

Thanks

Nabil Hanna AHC/FDAI/ACP/CI